Fiber-optic Sensing: Chirped FBGs measure thermal gradients for biomedical applications

Applications such as medical laser thermal ablation and photodynamic or thermo therapies are more effective when there is a real-time spatial understanding of the thermal energy delivered to biological tissue as a function of tissue depth. Using chirped fiber Bragg grating (FBG) fiber-optic sensors, researchers from Nazarbayev University (Astana, Kazakhstan), Universita Campus Bio-Medico di Roma (Rome, Italy), Politecnico di Torino (Torino, Italy), the Institute of Image-Guided Surgery (IHU; Strasbourg, France), the Research Centre of Frascati (Rome, Italy), and the University of Naples Parthenope (Naples, Italy) have developed a new technique that can resolve submillimeter-scale temperature patterns and estimate temperature gradients to advance a variety of thermal biomedical applications.1

Chirped gratings

Most FBGs within an optical fiber are separated by 2–5 mm (center-to-center spacing) and contain gratings themselves that can be a millimeter to several millimeters long. Typical FBG fibers cannot be used to perform submillimeter temperature sensing by looking at the spatial contribution of individual multiplexed gratings. And even though distributed sensors operating in optical Fourier domain reflectometry (OFDR) mode can monitor temperature with 0.1 mm resolution, these reflected systems are bulky, expensive, vulnerable to fiber-bending effects and fiber tip reflections, and cannot operate in real time.

To circumvent these limitations, the researchers instead use large-bandwidth chirped FBGs (CFBGs) that act as a broadband FBG, with the reflection spectrum affected by the temperature and/or strain profile along the entire length of the grating. In effect, the grating itself serves as a distributed temperature sensor at submillimeter scales.

Using a white-light source to interrogate a fiber containing one broadband CFBG, the grating spectrum changes in accordance to the temperature variation in every portion of the grating. By reconstructing the spectral change of the grating, it is possible to estimate the temperature pattern along the whole sensor length, obtaining a temperature pattern with a millimeter-level resolution. This process is accomplished through an optimization routine that dynamically tracks the CFBG spectrum and reconstructs the thermal gradient.

The fiber itself is a standard single-mode fiber with one chirped grating having a 60 nm bandwidth around 1550 nm and a 50 mm sensing length.

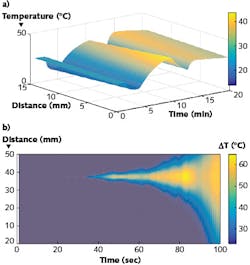

Polynomial gradients and Gaussian gradients typical in thermal ablation profiles can be quantified for tissue lengths from 1.5 to 5.0 cm and depths up to 20 mm using a decoding algorithm (see figure). Actual measurements taken during a thermal ablation procedure easily revealed thermal gradients with an accuracy of 0.5°C at 25°C.

"The possibility of turning a chirped FBG into a quasi-distributed sensor that measures gradients with a short spatial resolution is a significant improvement for biomedical sensors because it combines potential high-speed and low-cost interrogation with millimeter temperature or strain detection," says assistant professor Daniele Tosi of Nazarbayev University.

REFERENCE

1. S. Korganbayev et al., Opt. Fiber Technol., 41, 48–55 (2018).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.