Fiber-optic Components: Saturable absorber uses both single-mode and graded-index multimode fibers

In mode-locked lasers, saturable absorbers are critical components for the creation of ultrafast pulses. Unfortunately, carbon-nanotube (CNT)-, graphene-, or semiconductor saturable absorber mirror (SESAM)-based saturable absorbers often have a narrow bandwidth range, high cost, and limited robustness (in terms of lifetime) as power levels increase—even if applied to side-polished or tapered optical fibers.

Alternative methods of all-fiber-based saturable absorbers offer much higher power thresholds and have been demonstrated by researchers at China Jiliang University (Hangzhou, China) and the National Institute of Metrology (Beijing, China).1

GIMF, nonlinear multimodal interference

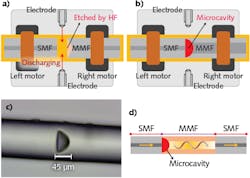

The self-phase modulation (SPM) and cross-phase modulation (XPM) effects that occur because of nonlinear multimodal interference (MMI) in graded-index multimode fibers (GIMFs) had not previously been able to produce a saturable absorber effect. However, the researchers acid-etched a GIMF (23.7 cm long) to produce a microcavity because of the different corrosion characteristics of the core and cladding. This GIMF with microcavity was then fusion-spliced to two sections of standard single-mode fiber (SMF) to produce a microcavity-containing SMF-GIMF-SMF structure (see figure).

As the GIMF section of fiber is bent, its mode-field distribution is varied, which increases the nonlinear SPM and XPM effects within the fiber and its cavity, leading to a change in the self-focusing length and thus creating a saturable-absorber-equivalent effect.

Critical to the operation of this all-fiber saturable absorber is the bending state of the spliced fiber section and the ability to maintain higher-order modes within the optical fiber section. Compared to other saturable absorbers, this all-fiber design is low in cost, easy to fabricate, and has a much higher damage threshold than hybrid fiber designs.

Quantitative analysis of the saturable absorber was performed using a fiber laser pumped by a 400 mW, 1480 nm laser diode using a 1480/1550 nm wavelength division multiplexer (WDM) into a 1.2 m section of erbium-doped gain fiber with peak absorption of 55 dB/m at 1530 nm. The saturable absorbing section of SMF-GIMF-SMF fiber was placed between a polarization controller and an output coupler on the fiber laser to induce mode-locking.

At a pump power of 92.3 mW, a 14.34 MHz pulse repetition rate was observed with interpulse intensity fluctuation of <5% and pulse energy of 49.2 W peak power.

“Compared to other saturable absorbers such as graphene and other 2D materials that are attached to the end face of the fiber or deposited on tapered or side-polished fiber, the main advantages of our device are its simple preparation method, long service life, and, more importantly, the high damage threshold for scaling up the pulse energy and peak power in mode-locked fiber lasers,” says Zhaokun Wang, a researcher at China Jiliang University. “All the fibers used in the device are commercial fiber, and only simple corrosion and fusion-splicing operations are required.”

REFERENCE

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.