Brillouin optical time-domain analyzer is sensitive over a 72 km fiber length

Brillouin optical time-domain analyzer (BOTDA) sensors can be used to monitor lengths of optical fiber many kilometers long for the distribution of temperature and strain along the fiber. Scientists at Nanjing University (Nanjing, China) and Guangxi Normal University (Guilin, China) have developed a BODTA that has a fine enough resolution to be used to locate localized irregularities in the fiber.

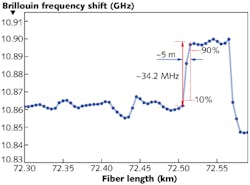

A BOTDA relies on the interaction of a continuous-wave (CW) probe signal with a counterpropagating optical pump pulse via stimulated Brillouin scattering (SBS). The return signal is changed in power by fiber irregularities. In the new sensor, coherent detection lowers the noise, and a double-sideband probe beam (containing both the Stokes and the anti-Stokes component) helps to reduce nonlocal effects that otherwise wash out the localized signal. The BODTA was used to measure along a 72.6 km fiber with 5 m resolution (the figure shows data taken, including a short section of fiber heated about 30°C higher than the rest of the fiber) and an estimated temperature uncertainty of 1.8°C, with no Raman amplification needed. The BODTA technique requires light to be input at both ends of the fiber; if there’s a fiber break, the setup can also be used from one end as a coherent optical time-domain reflectometer (COTDR) to determine the break position to 100 m spatial resolution. Contact Xuping Zhang at [email protected].

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.