FIBER LASERS: Pulsed fiber lasers reach 50 kW peak power at < 100 ps pulse duration

MOTOKI KAKUI

Pulsed fiber lasers (PFLs) are widely used for micromachining applications because of their excellent beam quality, compactness, maintenance-free operation, and high wall-plug efficiency. In particular, master-oscillator power-amplifier (MOPA)-type PFLs feature great flexibility in pulse duration and repetition rate when using a directly modulated laser diode as a seed laser.1, 2 In most cases, however, the peak power is in the range of 10-20 kW and the typical pulse duration is longer than 10 ns, which can cause undesirable thermal effects—such as debris buildup or dross and recasting (debris that re-solidifies on the object being worked)—during materials processing applications. In order to avoid thermal damage, ultrafast pulses with durations in the femto and picosecond range are typically used for ablative material removal with minimal heat-affected zone.

Ultrashort pulses are currently provided by mode-locked lasers such as solid-state Ti:sapphire designs, and fiber lasers manufactured by companies like IMRA America (Ann Arbor, MI), Raydiance (Petaluma, CA), Genia Photonics (Lasalle, QC, Canada), PolarOnyx (San Jose, CA), and others. But it is well known that Ti:sapphire and other mode-locked lasers are bulky and expensive—typically priced at $150,000 or more. In addition, the mode-locking operation requires precise alignment and the pulse duration is rigidly determined by the hardware structure; namely, the cavity length and the gain bandwidth. Ultrafast fiber lasers rely on complex pulse compression designs, and the practical applicability of these lasers is similarly limited by high cost. Finally, ultrashort pulse lasers do not always produce acceptable process results for many kinds of composite materials containing metal, plastic, glass, and other materials. Nanosecond pulses, for example, are preferable to picosecond pulses in the case of tin-oxide (SnO2) layer ablation on thin-film solar cells.3

To optimize process performance and value, users are seeking compact and cost-effective lasers that feature a widely tunable pulse duration that ranges from pico to nanoseconds. At Photonics West 2011 in San Francisco, CA, Sumitomo Electric Industries presented its SumiLas PFL featuring a variety of operational modes. In the standard mode, the pulse duration can be varied from 1 to 20 ns with a typical output power of 15 W at 1060 nm. The short-pulse mode also provides up to 50 kW peak power and adjustable pulse durations of 60 ps to 1 ns with average power up to 15 W. A long-pulse mode offers 1 µs pulses and 15 W. In any mode, the repetition rate can be varied from 100 kHz to 1 MHz. A green SumiLas operating at 530 nm with 5 W average power is also available.

Pulse-trimming technique

SumiLas achieves its performance by using a directly modulated laser diode as a master oscillator (MO). For wide pulse-duration tunability, a pulse generator (PG) has been developed that offers two operational modes; namely, a high-speed binary signal in Mode-A, and an arbitrary amplitude signal with a time constant of 100 ns in Mode-B. Mode-A is used for both the standard and the short-pulse mode of SumiLas.

Switching between the standard and the short-pulse modes is accomplished through pulse trimming, wherein a dichroic filter with a carefully optimized cut-off wavelength selects a portion of the MO output that is delivered to the amplifier stage (see Fig. 1). The initial overshoot output region of the filter is used for the sub-nanosecond short-pulse mode while the convex-shaped primary region is used for the standard and long-pulse mode. Pulse-duration flexibility is achieved by controlling the electronically modulated MO pulse duration and shape. For the standard mode, the full-width half maximum (FWHM) of the optical output pulse can be tuned from 1 to 20 ns. Using Mode-B of the PG, 1 µs pulses are obtained by compensating the transient response of the PA by tailoring the shape of the electronically modulated MO pulse such that it rises very slowly and gradually.

In the short-pulse mode, the FWHM of the overshoot pulse of the MO is always much shorter than 1 ns—typically in the range from 100 to 200 ps. Amplifying the initial overshoot pulse with a specially designed power amplifier (PA) enables high peak powers.

Power amplifier design

By careful control of the gain/extraction distribution in the PA, output pulse durations from 60 ps to 1 ns with peak powers greater than 50 kW are possible. For the short-pulse mode, note that the initial overshoot portion of the MO is followed by a pedestal region with duration of several nanoseconds. The extremely high-gain PA is designed so that the initial pulse is selectively amplified by the intense transient response of the population inversion of ytterbium (Yb) ions. At the same time, the nanosecond pedestal region is suppressed by the spectral gain non-uniformity.

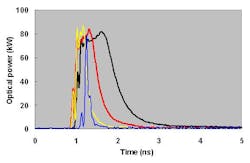

Since the average power of the initial overshoot signal is much lower than that of the original pulses by more than 20 dB, the optical power launched into the PA almost vanishes. Unfortunately, the risk of self-pulsation within the PA steeply increases for lower input power (namely the MO output power) and/or for higher gain, which could result in catastrophic damage of the various optical components or even fiber fusion. Moreover, the population inversion near the input end of the Yb-doped fiber becomes very high, which results in photo-darkening—an increase in the background optical fiber loss due to permanent damage within the fiber itself.4 To overcome these difficulties, the power excursion along the PA has been carefully designed and the Yb ion concentration has been optimized along the fiber length, enabling high peak power, pulses as short as 60 ps, and peak powers as high as 80 kW (see Fig. 2).5The wide-ranging pulse-duration tunability for SumiLas is useful in a variety of applications including thin-film solar cell processing, surface texturing, the ablation of polyimide, transparent-material processing, and micro-welding of metal tissues. Exploration of new applications including light detection and ranging (LIDAR) is currently under investigation.

REFERENCES

1. K. T. Vu et al., Opt. Exp. 14, 23, 10996-11001 (2006).

2. S. T. Hendow et al., ICALEO 2009, Orlando, FL, paper M209 (2009).

3. S. Tamaoki et al., ICALEO 2010, Anaheim, CA, paper M1306 (2010).

4. J. Koponen et al., CLEO/Europe 2005, Munich, Germany, paper CP2-2-THU (2005).

5. United States patent #7532391

Motoki Kakui is a project manager at Sumitomo Electric Industries, Ltd., 1, Taya-cho, Sakae-ku, Yokohama, 244-8588, Japan; e-mail: [email protected]; http://global-sei.com.