AUTOMOTIVE FIBER: Automobiles make the ‘MOST’ use of plastic optical fiber

MASAHIKO OTAKE

Plastic optical fiber (POF) has been used in automotive networking systems since 1998 after successful introduction by Mercedes Benz, spurring the introduction of the Media Oriented Systems Transport (MOST) standard—a reliable and robust network protocol for an optimized multimedia of entertainment and information. The MOST standard is constructed by the MOST Cooperation (Karlsruhe, Germany; www.mostcooperation.com), which is based on a partnership of carmakers, system architects, and key component suppliers that together define and adopt a common multimedia network protocol and application object model.

The MOST standard specifies POF as the physical data transmission medium based on its light weight, mechanical flexibility and strength, high bandwidth, electromagnetic interference (EMI)-free operation, and easy connection ability. Today, six international car makers and more than 60 key component suppliers have cooperated to enable the adoption of the MOST standard in more than 115 vehicle models, and cars with the latest generation MOST150 protocol technology are on the road in 2012.

Why POF?

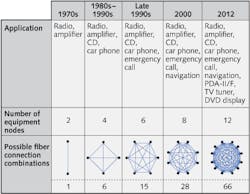

The number of electronic devices in a car increases year by year, primarily due to an increase in the entertainment equipment desired for modern passenger cars—from simple radios in the 1970s to radios, DVD players, TVs, and even GPS consoles. To realize ubiquitous access to multiple digital equipment sites in a car, each equipment site or node must be connected, leading to an exponential increase in the number of communication cables within the vehicle (see Fig. 1).

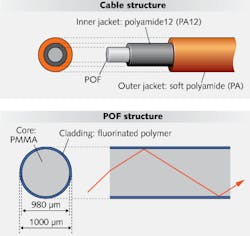

This ubiquitous connection need is a huge problem in networking system designs for automotive fiber from the viewpoint of both physical space and system load. Consequently, POF is specified in the MOST standard to achieve the lowest overall system weight and easiest connectivity. Common POFs in use today typically have a 980-μm-diameter polymethylmethacrylate (PMMA) core and a 1000-μm-diameter fluorinated polymer cladding (see Fig. 2). The fiber is jacketed with polyamide (PA) material to enhance its robustness in vehicle use.The high numerical aperture (typically 0.50 to 0.58), easy connection ability, and mechanical strength and flexibility of POF have cemented its use in automotive infotainment (information and entertainment) networking systems in passenger cars since the late 1990s. A typical automotive POF network uses 660 nm light-emitting diode (LED) sources and photodiode receivers. Transceivers for POF have been mass-produced for more than 30 years, making them a cost-effective networking component.

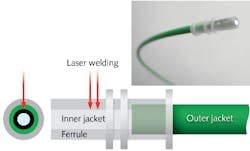

The POF cable and connectors in the MOST standard have a simple structure, making them as easy to produce and connect as copper cables. In an automated production line, end termination is completed in two seconds using a laser welding method (see Fig. 3). An inline POF coupler is used for fiber-to-fiber connection between equipment nodes.MOST network evolution

In 1998, Mercedes Benz adopted the D2B (digital domestic data bus) car networking system architecture using POF for its S-class series of automobiles. The D2B architecture consisted of a ring topology operating at 4–10 Mbit/s and was the first information entertainment networking system that united GPS navigation systems, audio, radio, and car phone. This networking system enabled passengers to control each multimedia source through a central console panel.

With the success of the D2B system, the MOST Cooperation was founded in 1998 to standardize the multimedia networking technology and improve on the D2B architecture. Unlike D2B, the MOST standard was designed as a synchronous network system. A timing master sends the clock asynchronous and continuous data signals to all slave equipment, so that all the equipment is synchronized. This architecture avoids buffering and sample rate conversion.

The first mass-produced vehicle to use the MOST standard was the BMW 7 Series in 2001. After BMW’s adoption of MOST, Daimler, Audi, Porsche, Volvo, and Saab followed, with more than 115 vehicle models adopting the MOST standard today. And in 2012, Audi will continue the MOST tradition by implementing the MOST150 standard on its A3 model. The MOST150 standard again uses a ring topology to achieve its 150 Mbit/s transmission speed to improve the performance of each component used. The speed increase was enabled by enhancement of optical devices (transmitter and receiver) and improvements in LED drivers and network controllers.

Future POF requirements

There are several network protocols for a car network such as low-speed CAN (Controller Area Network), LIN (Local Interconnect Network), and high-speed CAN. Each protocol is classified as being part of the power train, body control, information control, or safety information.

Regarding safety, it has been common practice to prepare the communications network system separately from the body control system to ensure safety. So far, the bandwidth needed for adequate vehicle safety controls is 10 Mbit/s; however, new safety technologies such as advanced driver assistance systems (ADAS) are under consideration by car manufacturers and challenging the current MOST specifications.

The noise-free, weight-saving media features derived from POF networking systems, such as broadband capability, will prompt system engineers to improve the MOST requirements. Fortunately, the standards continue to evolve and already a 105ºC heat-resistant cable has been developed to supersede the former 85ºC cable. Apart from networking, POF can also be used for ambient lighting in a car, addressing both aesthetic functions like cup holders and mood lighting, as well as safety lighting concerns such as door and foot lighting.

Plastic optical fiber has been meeting the demands of the world’s premium car networking systems since 1998. Third-generation MOST150 standards are just now being implemented, but new POF designs are anticipated in order to address not only infotainment but also automotive lighting requirements for this 21st century and beyond.

Masahiko Otake is assistant manager at Mitsubishi Rayon Co., Ltd., 1-1, Marunouchi-1 chome, Chiyoda-ku, Tokyo, 100-8253 Japan; e-mail: [email protected]; www.mrc.co.jp.