TEST & MEASUREMENT: Optical tests rise to the challenge of specialty fibers

DAVE KRITLER, FREDERIC SCHILDMEYER, AND BRADLEY MATSON

It seems like optical fiber is everywhere today, installed in our offices, schools, hospitals, and homes, and even in the cars we drive and the planes we ride. From the apparent ubiquity of fiber-optic communications systems, one could conclude that this once "high-tech" technology has fully matured, as the optical fiber at the core of these systems seems like a commodity. Although the casual observer might believe that the quality-control (QC) testing performed by optical-fiber producers is minimal, measurement challenges still remain for both in-process and final QC testing of standard telecom and datacom fibers.

Unlike the early days of the communications industry, measurement challenges are now more productivity related than technical. This is largely due to two factors: first, industry standards have been implemented for virtually every critical fiber parameter and, second, commercial test equipment has been available to measure all critical fiber parameters in an efficient and cost-effective way. The main problem conventional fiber manufacturers face today—besides dealing with the obsolescence of test equipment brought to market during the telecom boom—is ensuring that their test capability is evolving to enable the most precise and fastest measurements possible.

The situation is quite different in the comparatively young specialty-fiber world, where there are few industry-standard measurement conventions, and where the commercial test equipment designed for conventional fibers is either not quite the right fit or totally inadequate. But, as it was in the 1980s and 1990s, this mismatch of measurement needs and capabilities in a growing market is what drives suppliers of production test equipment like Photon Kinetics to develop the kind of test solutions that specialty-fiber manufacturers need to refine manufacturing processes and reduce costs—truly helping optical fibers to become as ubquitous as they seem to be.

Post-bubble challenges and opportunities

Fiber manufacturers who survived the capacity contraction that followed the bursting of the bubble are generally experiencing improved market conditions for their products. Thanks to network build-outs to the neighborhood, to the office, and to the home, demand for conventional fiber and cable is higher than it was a few years ago. However, a highly competitive market environment means that margins continue to tighten and pressure remains on manufacturers to keep a lid on production costs and, if possible, reduce them.

This objective is challenging: fiber production facilities built during the boom and then mothballed during the bust have aged, and so has the test equipment that was purchased to support the expansions. Bringing production capability back up to date is never straightforward. This is true even for test equipment, as instruments purchased during the boom almost a decade ago may be just around the corner from obsolescence. Compounding the challenge is the fact that many fiber manufacturers lost highly experienced test personnel during the bust. Together, these factors can seriously impact test productivity, production cost, and output.

But the glass is nowhere near empty. Increased sales volume for conventional fibers means that upgrading production capability can at least be considered now. Relatively new products such as optical time-domain reflectometers (OTDRs) optimized for production testing, easy-to-use tools for temporarily coupling fibers to test equipment, and test automation software that integrates test instruments with manufacturing information systems can all help to achieve production goals and even improve the productivity of inexperienced test technicians.

Meanwhile, on the other side of the market

In contrast with conventional fibers, the market environment for specialty optical fibers has been considerably more dynamic over the past few years. Specialty optical fibers are not only continuing to be used in telecom applications for components such as fiber amplifiers and in datacom applications for short-distance links, but they are also critical to a wide range of relatively new applications in the industrial, defense, medical, and automotive fields.

Large-diameter plastic fibers are being used for high-bandwidth data networks in luxury cars, and graded-index plastic optical fiber (POF) designs are now providing competition for conventional, laser-optimized multimode fibers in some 10 Gigabit Ethernet applications. Large-core silica fibers are being utilized for the delivery of semiconductor laser power, and rare-earth-doped, double-cladding single-mode designs are being used to generate and precisely deliver laser power for a variety of medical and industrial applications. And then there are the wide range of single-mode specialty fibers that are critical to the function of gyroscopes, instruments that log temperature of oil wells, and other fiber-based sensors.

The markets for specialty optical fibers are diverse, and many of them are growing. Manufacturers are reacting to improving prospects by investing in facilities to increase production capacity and upgrade capability. Like conventional fiber manufacturing, an essential tool for achieving either of these objectives is test equipment. Manufacturers need to find faster, more automated means of characterizing the unique properties of their fibers—and the preforms that are used to make them—to increase production capacity.

Although it may sound simple, the problem is that the vast majority of the production-oriented test and measurement equipment on the market today was designed for conventional, silica-based optical fibers: 7- to 62.5-µm-diameter cores with 125 µm claddings. These instruments were not designed to accommodate the range of fiber diameters or variety of geometries found in the specialty world or the materials used to construct these fibers, nor were they designed to measure all of the parameters that specialty fiber manufacturers are interested in.

Over the past few years, we have attempted to fill some of this information void by focusing development resources on evolving our line of production test equipment to address the unique measurement requirements of the specialty fiber manufacturing industry.

Geometry of large-diameter fiber

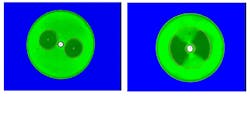

These fibers are not only larger in diameter than conventional fibers, but can also have numerical apertures that are much higher, up to 0.4 NA (see Fig. 1). Both characteristics make these fibers impossible to measure on conventional fiber geometry systems. However, modifications to the optics of a conventional fiber system enable the standard characteristics of these fibers to be measured (including core and cladding diameters, noncircularities, and core/clad concentricity).

Polarization-maintaining fiber and preform geometry

Polarization-maintaining (PM) fibers may also have larger (or smaller) diameters than conventional fibers, but their primary differentiator is the presence of stress rods embedded in the fiber cladding that create the birefringence necessary for polarizations to be maintained (see Fig. 2).Graded-index POF transmission

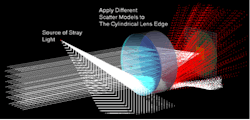

Current graded-index plastic optical fibers (GI-POF) manufactured with perfluorinated polymers have low attenuation, high bandwidth, and geometries that are similar to some conventional silica-based fibers. However, the unique optical characteristics of the polymers make measurement of a number of optical properties more challenging. Photon Kinetics has modified several measurements systems to accommodate these fibers. These include systems for characterizing a fiber's transmission properties including attenuation, bandwidth, differential mode delay, and chromatic dispersion, as well as geometric properties such as refractive-index profile (see Fig. 4).Test-equipment requirements

While the optical-fiber market has indeed matured greatly over the past decade, it is not to the point where the testing of optical fibers during the manufacturing process has become optional. Manufacturers still perform comprehensive characterization of every fiber produced, and often at several process stages. Testing strategies are driven by the intensely competitive market environment for standard optical fibers, which requires manufacturers to obtain measurement data at the lowest possible cost.

Nonconventional, specialty-fiber manufacturers share this need for high-quality measurement data, but they also have unique measurement requirements due to unique properties of the fibers they make. In the past, manufacturers satisfied these requirements with custom or home-built test equipment. But as the demand for their products has grown, so have their testing needs. Today's specialty manufacturers need test equipment that is more precise and more automated than their slower, difficult-to-maintain home-built systems. Fortunately, they can take advantage of much of the instrumentation that was developed for standard fibers. In most cases, factory-proven test systems for standard fibers can be modified to meet the unique needs of specialty-fiber manufacturers, giving them the same capability to produce higher-quality products and reduce manufacturing costs.

Dave Kritler is marketing manager and Frederic Schildmeyer and Bradley Matson are senior measurement engineers with Photon Kinetics, 9305 SW Gemini Drive, Beaverton, OR 97008; e-mail: [email protected]; www.photonkinetics.com.