Fiber-based sensor has 1 cm resolution to quickly detect structural problems in bridges and dams

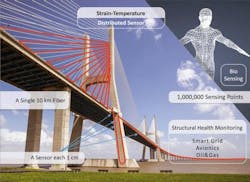

| A 4.5X-faster strain-temperature sensor measures 1 million sensing points over a single 10-kilometer of standard fiber. It could be useful for monitoring the integrity of large structures (dams, aircraft, bridges) and for biomedical sensing. (Credit: This work is a derivative from Vasco da Gama Bridge by Duncan Rawlinson used under CC BY-NC 2.0 and licensed by Alejandro Dominguez-Lopez, University of Alcala, under CC BY-NC 2.0) |

There is great interest in using fiber-optic distributed sensors to continually monitor the structural health of large structures such as dams or bridges. With 1 million sensing points, a newly developed fiber-optic distributed sensor could offer significantly faster detection of structural problems than is currently available.

Fiber optic distributed sensors are ideal for monitoring infrastructure because they can be used in harsh environments and in areas that lack a nearby power supply. If a single fiber is placed along the length of a bridge, for example, changes in the structure at any of the sensing points along the optical fiber will cause detectable changes in the light traveling down the fiber. Although the popularity of fiber-optic distributed sensors is growing, they are currently used primarily to detect leaks in oil pipes and to monitor for landslides along railroads.

Alejandro Dominguez-Lopez and his colleagues from the University of Alcala (UAH) in Spain and the Swiss Federal Institute of Technology (EPFL) now report the first fiber-optic distributed sensor that can sense strain and temperature changes from 1 million sensing points over a 10 km optical fiber (that's one sensor per centimeter of fiber) in less than 20 minutes.1

The new sensor uses Brillouin optical time-domain analysis, which requires pulsed and continuous-wave laser signals to interact. The new sensor is about 4.5 times faster than previously reported sensors with 1 million sensing points. The researchers demonstrated that they could measure the temperature of a hot spot to within 3 degrees Celsius from the end of a 10-kilometer long fiber.

"With fiber-based sensors, it is possible to precisely detect erosion or cracking before a dam fails, for example," said Alejandro Dominguez-Lopez from the University of Alcala (UAH) in Spain, from the research team that developed the new sensor. "Earlier detection of a problem means it might be possible to prevent it from getting worse or could provide more time for evacuation."

Source: https://www.eurekalert.org/pub_releases/2017-05/tos-nfs050417.php

REFERENCE:

1. A. Dominguez-Lopez et al., Optics Letters, Volume 42, Issue 10, 1903-1906 (2017). https://doi.org/10.1364/OL.42.001903