Wolfsburg, Germany - I have been invited by Volkswagen (VW) to attend a conference titled Neueste Entwicklungen der industriellen Lasertechnik, which roughly translates into Latest Developments of Industrial Laser Technology. This is a now an annual event presented by Volkswagen, ALAW/University of Michigan, and the IZB (International Suppliers Exchange) that is organized by Wolfsburg AG to be a platform for the latest developments and trends from the realm of the automobile industry.

At a pre-conference dinner attended by the speakers and invited guests there was sufficient time to discuss the latest developments with representatives from six automobile companies. Courtesy prevented me from taking copious notes on the many tidbits about laser activity that crossed the table over dinner. And I expected to hear many of these at the conference itself.

My concern the next day results from a look at the pre-printed proceedings, which include the presentations of 13 featured presenters and not the comments of five invited panelists in a session tilted Trends with Automotive OEMs.

I willingly accepted the invitation to attend this meeting because I am anxious to learn all that I can about the use of lasers in European automotive manufacturing and assembly operations. Frankly, what is happening, laser-wise, in automotive is driven primarily by what takes place in Europe. But the conference starts off with a six-speaker session on laser technology (CO2, disc, diode-pumped solid-state, fiber, and diode). It must be a German thing, wanting to know as much about the laser technology as they do about the engines in the cars they buy. Now, I see nothing wrong with this except it is typically a feature session at any conference that deals with lasers in the auto industry, and frankly it is beginning to wear a little thin.

My opinion, save the laser technology for a different venue and spend the time digging deeper into the systems and the applications. For example Norbert Höppe (Reis Robotics) and Dr. Peter Rippl (Kuka) gave us a look at laser robot system developments. Rippl is always a pleasure to listen to, except that he packs 60 minutes of valuable information into a 30-minute time slot, supported by slides so intense with data that I spend hours deciphering them later, showing the value of pre-published proceedings.

That said, and in a more upbeat mood, I responded positively to a presentation by Peter Busuttil (Comau Pico) who talked about a tube cutting application, featuring a laser robot system, at a well-known but unnamed leading U.S. motorcycle manufacturer. This system is also used to weld the bike frame using high-power Nd:YAG lasers from TRUMPF.

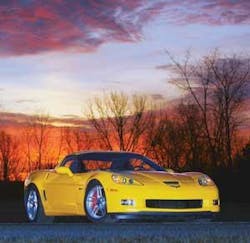

Richard Marando (Dana Corp.), Hans Hornig (BMW Group), and Masahiro Nishio (Toyota Motor Company) gave us a look at laser processing on the international scene. Marando talked about his company’s experience with lamp- and diode-pumped solid-state lasers and fiber laser cutting and welding applications on frame and body components, and he featured the new Corvette Z06 that uses high-power solid-state lasers to weld the aluminum transmission tunnels assembly. Hornig traced the history of laser welding at BMW from the earliest roof welding operations to the current laser brazing and hybrid welding applications on the new Series 5 and 6 vehicles. Nishio gave an overview of the many laser welding applications at Toyota on roof, trunk lid, cowl, and doors explaining how the laser improves fit, finish, and ride rigidity. Unfortunately he chose not to identify the various models that were shown in the photos he used to diagram the applications.

The closing session, a panel discussion led by Frank DiPietro, featured Per Lindal (Volvo), Klaus Loeffler (Volkswagen), Ricardo Yuba Sans (SEAT), Ralf Bernhardt (Daimler Chrysler), and Masahiro Nishio (Toyota) who were each given a few minutes to show some technology but were essentially grouped to answer questions from the more than 180 attendees. This group tantalized us with displays of countless applications that once again prove that the innovation in high-power laser and laser systems technology continues to be led by the auto industry.

Loeffler stated that 16 percent of the hot formed steel joints on the new Passat are laser welded, including a scanner application on the rear deck, and that laser brazing is used on the roof-to-side ring. He also said that VW had installed 17 TRUMPF laser cutting cells to trim hot formed parts. Yuba Sans said that SEAT is using laser brazing on the roof joint of the Vitro and that the entire underbody of the Sprinter is laser brazed. They use 23 lasers in 11 manufacturing cells. Lindal showed the A pillar of the C-70 , which is laser welded with a laser brazed cover. Finally, Bernhardt showed aluminum door inners of the S Class Mercedes that are laser welded with the company’s Robscan welding system.

All in all, the format of this conference with considerable time allowed for dialoging makes for an enlightening meeting that allows attendees to carry away useful information that can be applied in their plants. We understand that VW intends to continue these meetings and we look forward to the next session. - DAB