CHIRPED PULSE AMPLIFICATION: Synchronized CPAs produce ultrashort pulses for pump-probe experiments

Delay lines that introduce a quantifiable separation between laser pulses are necessary for time-resolved experiments in ultrafast science such as pump-probe spectroscopy. In many cases, experiments require variable delay between pump and probe pulses spanning the femtosecond to nanosecond range. In order to achieve such a large dynamic range with femtosecond step sizes, engineers at Newport Corp. (Irvine, CA) have developed a technique using two synchronized chirped-pulse amplifier (CPA) systems where a variable time delay on the seed pulse of one of the amplifiers can be introduced.1

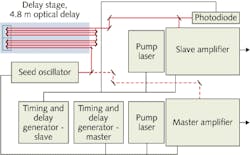

Synchronization on the femtosecond scale is accomplished by seeding two electronically synchronized amplifiers from the same oscillator. The dual-amplifier technique eliminates the influence of the delayed beam parameters on pump-probe experiments when several meters of optical delay is introduced.

Dual amplifiers

The system consists of a seed femtosecond oscillator that is fed into a beamsplitter; 80% of the reflected signal is sent to an optical-delay line that seeds into the slave amplifier and 20% is sent directly to the master amplifier (see figure). The optical delay line consists of a stage with 0.6 m travel and two corner-cube retroreflectors that allow eight passes of the beam for a 4.8 m total computer-controlled optical delay. Before entering the delay line, a 2X telescope reduces the beam divergence.

Because the seed pulse is divided into two replica pulses from one oscillator, the jitter between the output pulses from the two amplifiers is minimized. By delaying the slave-amplifier seed replica pulse in this dual-amplifier setup, the delay between two amplified pulses can be controlled. For an 80 MHz oscillator repetition rate, a controllable delay time up to 12 ns (with uncompromised beam quality) between two amplified pulses is possible.

The delay-time resolution of the setup is defined by the accuracy of the motorized delay line and stability of the optomechanical components. By choosing appropriate components, better than 30 fs resolution can easily be achieved. “Since CPAs run in saturation regime their output doesn’t depend on changes of the seed beam size when several meters of variable optical delay are introduced,” says Ruben Zadoyan, senior director of the Technology and Applications Center at Newport Corp. “As a result, the energy, pulsewidth, and spatial properties of the output of the slave amplifier remain unaffected. This approach will facilitate experiments interrogating dynamics of systems on large time scales with high time resolution.”

REFERENCE

1. “Synchronization of Two Spectra-Physics Spitfire Pro Amplifiers for Pump-Probe Experiments,” Newport Application Note 43; http://assets.newport.com/webDocuments-EN/images/14076.PDF.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.