JEAN-FRANCOIS SEURIN, ROBERT VAN LEEUWEN, and CHUNI GHOSH

High-power vertical-cavity surface-emitting laser (VCSEL) technology has been in development for a number of years and is finally coming to maturity, with applications that now include high-power solid-state-laser pumping including replacement of flashlamps, high-energy speckle-free illumination, material ablation, and medicine.1 This technology is replacing the incumbent technology of edge-emitting lasers in demanding applications. Users are seeking out high-power VCSEL arrays for applications where a much higher level of reliability, higher operating temperature, good-quality uniform flat-top beam profile, and simpler packaging and lower cost are required. Vertical cavity laser arrays are now available with a continuous-wave (CW) power of several hundred watts and quasi-CW (QCW) power of greater than 800 W from arrays that are only several millimeters on a side.

VCSEL array power levels

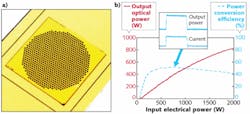

In a VCSEL, the two mirrors forming the laser cavity are grown epitaxially on the wafer and are separated by a gain medium consisting of multiple quantum wells.1 Single-device multimode VCSELs now deliver a maximum power of 5 W, while singlemode devices deliver a maximum power of 1 W. Multimode 2D arrays can deliver a CW power of 230 W (limited by thermal roll-over) from a 5 × 5 mm chip with a 0.22 cm2 emission area, corresponding to a power density of 1 kW/cm2 at 976 nm pump wavelength. Such 2D VCSEL arrays have demonstrated several desirable properties, including a narrow spectral linewidth (0.8 nm), a stable emission wavelength with respect to temperature (0.07 nm/K), and a circular, uniform, low-divergence beam (17° full divergence angle) without the need for optics. This is in contrast to edge-emitters, which typically exhibit a 3 to 5 nm spectral linewidth, a strong dependence of the emission wavelength on temperature (about 0.33 nm/K), and an elliptical, high-diverging output beam (greater than 35° divergence in one direction is typical). Singlemode VCSEL arrays delivering more than 100 W of power have been built and used mainly in illumination applications requiring narrow-divergence beams.

High-power 2D VCSEL arrays can also be used in QCW operation, in which case the power levels and power densities tend to be much higher (see Fig. 1). The output power under QCW operation of a 2D VCSEL array of 5 × 5 mm chip size (0.22 cm2 emission area) designed for 976 nm emission exceeds 800 W, and the peak power-conversion efficiency of the array is 52% at a 500 W output. Furthermore, the output power level remains constant during the 250 μs pulse, which is important for certain QCW pumping applications.

High-temperature operation is important for users who need to use diode-pumped lasers or illuminators outdoors or in other harsh environments. The high-temperature-operation ability of VCSEL arrays allows them to be used without chillers, instead relying on a simple water pump, radiator, and fan cooling—much like cooling a car engine. Indeed, it has been shown that VCSELs can be operated at temperatures up to 200°C.2 In contrast, chillers are required when pumping solid-state lasers with edge-emitting lasers, and the water temperature needs to be maintained within a tight range to avoid wavelength drift of the pump diodes.

Solid-state laser pumping

Recently high-power, high-efficiency 2D VCSEL arrays emitting at around 808 nm have become available and are being used as pump sources for diode-pumped solid-state (DPSS) lasers—for example, high-energy Q-switched Nd:YAG lasers for blue and UV applications that include underwater transmission, LIDAR, designation, rangefinding, and so on.3, 4 High-power VCSEL arrays are particularly well suited for constructing compact side- and end-pumped DPSS lasers, as the arrays can be arranged in a layout optimal for uniform pumping of the gain medium. We have used VCSEL modules of four 2D arrays to deliver more than 800 W average power in 250 μs pulses for end-pumping a Q-switched 1064 nm Nd:YAG laser, obtaining an energy of 40 mJ per pulse. For end- and side-pumping applications, 2D VCSEL arrays can potentially be assembled directly against the facets of the gain medium without the need for optics or isolators.

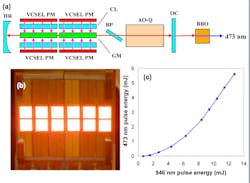

We have used VCSEL modules containing several 2D arrays for side-pumping of a passively Q-switched 1064 nm Nd:YAG laser that was frequency-quadrupled to produce 0.8 mJ, 266 nm UV pulses of 2.7 ns duration. In addition, we used the same VCSEL modules to pump an actively Q-switched Nd:YAG cavity operating at the 946 nm transition, which was frequency-doubled to generate more than 10 mJ of blue (473 nm) pulses of 17 ns duration (see Fig. 2). The pump modules comprised six pairs of VCSEL arrays with square emission areas, connected in series to reduce the drive-current requirement. Each VCSEL chip had a peak power output of 150 W; the output from the entire module was 1.8 kW with high uniformity.In addition, VCSEL arrays are being used to replace flashlamps for pumping; the configuration, packaging, and low cost of VCSELs make them particularly suitable for this purpose.

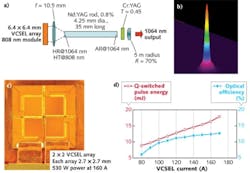

Very high Q-switched output power can be obtained from end-pumping as well. At the Army Night Vision and Electronic Sensors Directorate (NVESD; Fort Belvoir, VA), 6.4 × 6.4 mm pump modules consisting of four 2.7 × 2.7 mm VCSEL arrays delivering a power of 530 W with 160 A current result in 17 mJ of Q-switched energy (see Fig. 3). The mode quality of the beam is extremely good. The NVESD has used similar arrays for obtaining 9 mJ of pulse energy at 1550 nm for ranging applications from "mono-block" lasers.Illumination

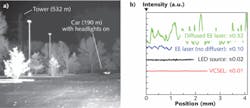

One major application of high-power VCSEL arrays is illumination.5 A nighttime exterior scene illuminated by a 2D VCSEL array without any optics and captured with a simple CCD camera results in very good image quality, as VCSEL arrays are intrinsically speckle free (see Fig. 4). Illumination often requires field operation at high temperatures, which is not a problem for VCSELs since they have been shown to work under extreme environments.For illumination and other applications, VCSEL arrays have many advantages such as low manufacturing costs, very high reliability (thousands of times better than for edge-emitters), high-temperature operation, intrinsic spectral stability, excellent beam quality, and the absence of catastrophic optical damage—a major failure mode for edge-emitting lasers.6 The combination of these qualities has the potential to open up entirely new applications for high-power VCSELs as well.

REFERENCES

1. J.F. Seurin et al., Proc. SPIE, 6908, 690808 (2008).

2. R.A. Morgan et al., IEEE Photon. Technol. Lett., 7, 5, 441 (1995).

3. J.F. Seurin et al., Proc. SPIE, 7229, 722903 (2009).

4. R. Van Leeuwen et al., Proc. SPIE, 7912, 7912–36 (2011).

5. J.F. Seurin et al., Proc. SPIE, 7952, 7952–15 (2011).

6. A. Moser et al., J. Appl. Phys., 71, 10, 4848 (1992).

Jean-Francois Seurin, Robert Van Leeuwen, and Chuni Ghosh are at Princeton Optronics, 1 Electronics Dr., Mercerville, NJ; e-mail: [email protected]; www.princetonoptronics.com.