GPON design gives it greater efficiency

In Jeff Hecht’s Photonic Frontiers, “Fiber to the home takes aim at a ‘100-megabit nation’ ” (September, p. 83; www.laserfocusworld.com/articles/338741) his comparison of the GPON (Gigabit PON) and EPON formats contains some inaccuracies that should be corrected because they are common; one was recently repeated to me by a customer at the Fiber to the Home conference.

The article stated: “Ethernet PON (EPON) transmits 1 Gbit/s in Ethernet-format variable-length packets rather than using time-division multiplexing. Advocates say this makes data transmission more efficient because the Internet uses the same packet-switching technique.” The reality is that GPON also uses variable-length packets and is no more or less a TDM protocol than EPON.

This misunderstanding evidently stems from a belief that, since GPON was an outgrowth of the earlier BPON (broadband PON) standard, it also uses the ATM protocol with fixed-length packets. In fact, the GPON standard has for several years discouraged the use of ATM. All GPON implementations instead use the GPON encapsulation method (GEM), which generates variable-length packets.

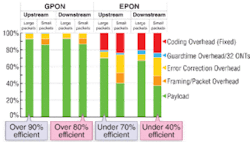

In reality, GPON is much more efficient than EPON at carrying Ethernet traffic because the two were designed for somewhat different applications. For example, EPON was designed with longer guard times between the end of one packet and the start of the next from a different ONT (Optical Network Terminal) to reduce complexity and cost, but GPON was designed with tighter guard times to increase efficiency. Likewise, GPON was designed to have lower error correction and other overhead. As a result, the efficiency of EPON is at best 70%, but that of GPON is at worst more than 80%. For transmission of smaller packets (such as most traffic other than file transfers), the efficiency differences between EPON and GPON are even greater. The attached graph shows these differences for large and small packet sizes.

Differences in the current application of EPON and GPON are primarily due to the much earlier availability of the EPON standard and its initially lower cost. The initial price differential of the underlying technology itself has largely disappeared, and cost differentials are now mostly due to application differences.

Typically, EPON has been used by carriers that wanted to provide data service, but not voice or a radio-frequency video overlay, with indoor terminals. This application is especially prevalent in Asia. GPON equipment was originally developed for large U.S. carriers who wanted outdoor terminals with voice and RF video, which made the end terminals more expensive. However, indoor, data-only GPON terminals are now available as well. My company, Hitachi, makes both EPON and GPON products, and each has its applications, but today the prevailing choice for new fiber-to-the-home installations is GPON.

Scott T. Wilkinson

Vice President

Hitachi Telecommunications

Norcross, GA 30067

Editor’s note: The online article at www.laserfocusworld.com/articles/338741 has been corrected to reflect the comments in this letter. Laser Focus World regrets the error.