Optical-fiber-based broadband light sources are desirable for applications such as spectroscopy or optical coherence tomography because, being effectively point sources, they have very high beam quality and spatial coherence. Various types of fiber sources exist, including white-light supercontinuum and doped superfluorescent, and bandwidths can reach from less than 100 up to 300 nm or so. But researchers at the University of Bern (Bern, Switzerland) and Silitec Fibers (Boudry, Switzerland) have far surpassed these bandwidths with their own fiber design, which in one configuration boasts an output spectrum that spans 365 to 2300 nm.

Two configurations were tested: one with seven separate cores doped with different rare-earth oxides, and another with a single core doped with all the oxides at once. The fibers were fabricated by filling fused-silica tubes with granulated mixtures of rare-earth oxides and aluminum oxide (the aluminum oxide raises the refractive index and also keeps the rare-earth ions from clustering) to make a preform; evacuating, heating, and drawing the preform to a 1.24-mm-diameter fiber; placing the fiber in another preform and packing with undoped granulated silica, then evacuating, heating, and drawing the second preform into a fiber (drawn to core diameters of from 5 to 16 µm). The oxides simultaneously used include those of neodymium, holmium, erbium, thulium, and ytterbium.

A multicore fiber with 5 µm cores was pumped with a Ti:sapphire laser emitting at 804 nm; its output was sensed either with a silicon-based CCD, or with one of three spectrometers having sensing ranges of 190 to 860, 650 to 1100, and 900 to 2500 nm, respectively (the pump light was suppressed with a filter). The output spectrum spanned 925 to 2300 nm, with only a small gap below 1300 nm, and also included peaks at 522 and 546 nm due to excited-state absorption.

Next, a single-core fiber with a 6.5 µm core and a numerical aperture of 0.1 was pumped with the Ti:sapphire laser, creating a spectrum slightly but not radically different from that of the multicore fiber, except for the region of shorter wavelength than the pump laser, which showed several extra peaks in this range, resulting from excited-state absorption, energy transfer, and energy-transfer upconversion, ranging down to 365 nm. A 34 μW output power translated into a radiance of 3 kW sr-1 cm-2.

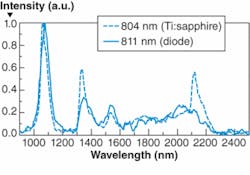

Finally, the researchers replaced the Ti:sapphire laser with a laser diode emitting at 811 nm; the single-core fiber emitted a similar but lower-power spectrum (see figure). The device, diode-pumped and emitting a spectrum in the very useful range of 925 to 2100 nm, shows promise as a high-quality, superbroadband source for many applications.

REFERENCE

1. L. Di Labio et al., Optics Lett. 33(10) 1050 (May 15, 2008).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.