Improved 'nose' is developed for trace-gas monitoring

Cavity-ring-down spectroscopy (CRDS) is an established technique for quantitative absorption measurements to determine the chemical composition of a sample under test. Unfortunately, the technique can suffer from large background fluctuations in absolute light intensity that can obscure the detection of weak absorptions. It was recently announced that a variation on CRDS has been developed that increases sensitivity of this technique by a factor of 1000.1

Vescent Photonics (Denver, CO) has signed a Cooperative Research and Development agreement with the National Institute of Standards and Technology (NIST; Boulder, CO) and hopes to commercialize the ultrasensitive technique that was developed by Jun Ye, Long-Sheng Ma, and John Hall of the Joint Institute of Laboratory Astrophysics (JILA), a joint institute of NIST and the University of Colorado at Boulder. Vescent plans to apply the public-domain optical “nose” technique to detecting and quantifying trace quantities of atmospheric gases. The ultrasensitive technique is called noise-immune cavity-enhanced optical-heterodyne molecular spectroscopy (NICE-OHMS).

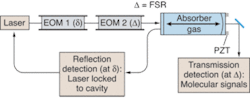

In NICE-OHMS, laser light passes through two electro-optic modulators before entering a high-finesse cavity containing the sample gas (see figure). Radio-frequency-modulation (FM) sidebands placed on the laser beam are used to lock the laser frequency on a cavity-resonance mode. Another set of modulation sidebands, with frequency chosen to match the cavity free-spectral range, is used to probe the intracavity molecular signal. A piezoelectric transducer mounted on one of the cavity mirrors is used to scan the cavity across molecular resonances.

By combining the high-finesse external optical cavity (to enhance the intrinsic resonance contrast of the target molecules) with a high-frequency modulation scheme to suppress background noise during signal recovery, the optical nose makes the detection process insensitive to noise in the laser frequency relative to the cavity and enables the cavity finesse to enhance detection sensitivity without any noise penalty. The optical cavity enhances the optical-absorption contrast of atomic or molecular samples by extending the effective length of the detector cell by a factor or two; that is, the cavity creates a sufficiently high build-up field to enable strong molecular radiation, which can be resonantly coupled out for detection.

In theory, researchers should be able to design optical cavities with sufficient sensitivity to observe the sample’s absorption of individual photons. In practice, however, noise coming from different parts of the system overshadows this sensitivity, particularly in low-frequency ranges-hence the need for a detection method that can differentiate weak absorption signals from system noise. Fortunately, the FM-spectroscopy technique offers detection sensitivity near the limit determined by fundamental quantum noise.

The power of the NICE-OHMS technique lies in its combination of cavity enhancement with FM spectroscopy for signal recovery. The JILA researchers report that background noise associated with their optical (laser) source and with cavity instability has been reduced or eliminated. Under research conditions, the technique has demonstrated a detection sensitivity of 5 × 10-13 of integrated absorption (1 × 10-14/cm) over a one-second averaging time. These sensitivities are an improvement over the values of 1 × 10-10 achieved by the team in the year 2000; the improved sensitivities are the result of years of work and numerous innovations by the JILA scientists.2, 3

Coherent spectroscopic techniques such as NICE-OHMS may soon offer tangible benefits such as the ability to detect molecules of explosives in luggage or clothing at airports or other high-security installations. “I am really glad industrial colleagues are starting to commercialize this powerful technique, which has so far been explored in seven research labs since its invention at JILA in 1996,” says JILA researcher Jun Ye.

REFERENCES

1. “Designing an Ultrasensitive ‘Optical Nose’ for Chemicals,” NIST Tech Beat (Nov. 10, 2004).

2. J. Ye, L.-S. Ma, and J. L. Hall, J. Opt. Soc. Am. B 15, 6 (1998).

3. J. Ye and J. L. Hall, “Experimental Methods in the Physical Sciences” in Cavity-Enhanced Spectroscopy, R. D. van Zee and J. P. Looney, Academic Press, New York, 83 (2002).