Lasers in Transportation: Laser ignition quantitatively improves performance of gasoline engines

Only by quantitatively improving performance (and cost) compared to electric spark plugs (ESPs) will laser ignition (LI) of gasoline engines be considered for adoption by major automobile manufacturers. Researchers from the National Institute for Laser, Plasma and Radiation Physics and Renault Technologie Roumanie (both in Ilfov, Romania), and from University Politehnica of Bucharest (Bucharest, Romania) have achieved such advances in their design and quantifiable demonstration of an LI system using fiber-coupled, compact neodymium- and chromium-yttrium-aluminum-garnet (Nd:YAG/Cr4+:YAG) laser spark plugs.1

Compared to ESP ignition, LI has several advantages: 1) LI is delivered through an optical window on the engine cylinder wall, removing the ESP protruding electrode and allowing the flame to develop freely without quenching; 2) any internal part of the cylinder can be accessed and the fuel can be ignited at various spatial locations; and 3) multiple laser beams can be used to insure redundancy of ignition and potentially higher ignition efficiency through burst-mode operation.

Quantifying performance

The use of a 10.6 µm CO2 laser and a 1.06 µm Nd:YAG laser for LI have already shown increased peak engine pressure and higher brake power, as well as improved engine combustion stability. However, these were large, tabletop-sized laser systems and obviously not amenable to commercial implementation.

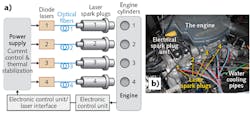

The Romanian researchers instead used a compact LI system that consisted of four Nd:YAG/Cr4+:YAG compact lasers pumped by 807 nm laser diodes, which were fiber-coupled using 600-µm-diameter fibers with a numerical aperture (NA) of 0.22 and operated in quasi-continuous-wave mode (see figure). With 250 μs pump-pulse duration and varied repetition rate from a few up to 100 Hz, laser pulses at 1.06 μm wavelength were delivered with 4 mJ energy and about 0.8 ns duration—corresponding to a peak pulse power of 5 MW from 40 mJ pump pulse energies.

The laser beam delivered by each laser spark plug (LSP) was collimated and then focused inside the corresponding cylinder of the engine. It is worthwhile to mention that the focusing position was chosen to match the point where ignition is made by the classical spark plug.

A sapphire window was used as the interface between an LSP and the corresponding engine cylinder. All optical elements (the Nd:YAG/Cr4+:YAG medium, lenses, and the sapphire plate) were embedded in the LSP metallic body with an epoxy adhesive resistant to temperature variations from -70° to 170°C and with high shear and peel strength.

Ignition experiments on a Renault multipoint fuel injection passenger car engine with four cylinders were completed using standard 30 mJ ESPs and LI using only one laser pulse per cycle (not in burst mode) to establish ignition equivalency. For a stoichiometric air-fuel ratio (meaning a ratio where, if the reactants burned completely, there would be no leftover fuel or air) operation, results showed 7.9% higher engine brake power, 7.4% decrease in brake-specific fuel consumption (BSFC), and 20% fewer carbon monoxide (CO) emissions with LI compared to conventional ESP ignition. Furthermore, LI of lean (a nonstoichiometric ratio of approximately 1.25, leaving excess air left over after combustion) air-fuel mixtures improved the engine brake power by 29% relative to ignition by ESP (of the same type of fuel), while BSFC decreased by 21% and CO was reduced by 30%.

“Vehicles powered by internal-combustion engines must be continually improved as human concerns about environmental impacts rise,” says professor Radu Chiriac from the Faculty of Mechanical Engineering at the University Politehnica of Bucharest. “Our laser spark plugs, with similar dimensions as classical electrical spark plugs, were used to operate a real car engine at stoichiometric air-fuel mixture [normal operation], but also at lean air-fuel mixtures, where less fuel is used. Improved engine performance and fewer exhaust emissions were obtained by laser ignition; faster ignition and more robust combustion initiation are thought to explain the improvements seen with laser ignition.”

REFERENCE

1. N. Pavel et al., Opt. Express, 27, 8, A385–A396 (2019).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.