Horsham, PA--PulseTor has selected Avo Photonics, an optoelectronic service company specializing in custom design and manufacturing, to advance the performance, packaging, and production of PulseTor's next-generation silicon photomultiplier (SiPM) detectors.

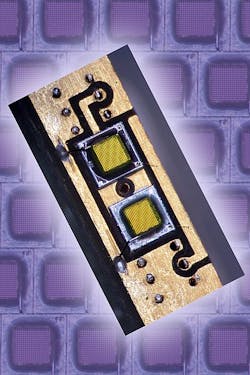

PulseTor’s SPRITE SiPM-based detector assemblies are used in electron imaging applications. The measurement requirements and high-vacuum operating environment that are characteristic of these applications impose challenging thermal, electrical, material, and mechanical packaging constraints. To But Avo Photonics' high-efficiency solution supports optional low temperature operation without the use of active cooling, while simultaneously providing vacuum compatibility and minimal package size.

"The component design and system engineering converged nicely to yield a manufacturable assembly which meets PulseTor’s expectations," remarks Todd Rixman, Avo's technical manager for this program.

Dr. Nicholas Barbi, CEO of PulseTor, comments, “Working with Avo was efficient and successful. They listened to our requirements and ideas and offered suggestions and improvements, all while being incredibly detailed in their analysis, design, and production. The degree of support and transparency provided by Avo were primary contributors to the success of the program.”

SOURCE: Avo Photonics