The Laser Focus World 2004 annual review and forecast of the laser markets is conducted in conjunction with Strategies Unlimited, an optoelectronics market research firm based in Mountain View, CA. Part I of the review reports on the overall market and focuses on nondiode-laser markets. Part II, written by Robert Steele of Strategies Unlimited, covers the diode-laser marketplace and will be published next month.

Most self-help groups believe that the only way up is to hit rock bottom first. If 2000–2002 was the laser industry's hangover from hell (see "Review and forecast of the laser markets," Laser Focus World, January 2003, p. 73), then 2003 was the recovery that needed lots of aspirin and TLC. Like the Little Red Engine that could, this industry has spent much of the last year chanting "I think I can, I think I can . . ."—and truth is, all that hard work is beginning to pay off.

Several global indicators support the laser industry's general consensus that business is improving, albeit only modestly. For one thing, it appears that the U.S. economy—still the largest market for laser and optoelectronics products—has finally begun to turn around, and analysts believe this trend is already being mirrored in other parts of the world.1 According to figures released by the U.S. government in November 2003, the U.S. economy grew at an annualized rate of 7.2% in the third quarter of 2003, an increase in gross domestic product greater than any since the first quarter of 1984 and the most broad-based gain in the U.S. economy in three years. More important for the high-tech industry is the news that investment by businesses grew at 11% (annualized), the fastest rate since early 2000.

Much of the credit for this trend is being given to the Bush Administration's aggressive spending increases and tax cuts, which have been targeted at stimulating economic growth.2 There are indications that these measures are also having an effect on employment numbers, which economists say is critical to transitioning to a self-sustaining recovery. The U.S. Department of Labor reported in early November that the U.S. unemployment rate fell to 6% and business payrolls jumped by 126,000 in October, the strongest growth all year (although jobs in the manufacturing sector continued to decline, down 41,000 in October). In addition, of the 286,000 jobs gained since July, 19% have been in the form of temporary jobs, which economists also point to as an early sign of economic recovery.

While this is certainly good news, the trickle-down effect on the high-tech sector—and the laser industry in particular—will take some time. The semiconductor-equipment market is still trying to get back on track, and no one even seems to talk about telecom anymore except in terms of bankruptcies, mergers, acquisitions, and what to do with all that nifty optoelectronic technology. Coherent (Santa Clara, CA), for example, reported a net loss of $46.5 million on sales of $406.2 million for 2003, compared to a net loss of $70.8 million on sales of $397.3 million in 2002. The bulk of the losses came from Coherent's subsidiary Lambda Physik (Göttingen, Germany)—which relies heavily on the semiconductor-equipment market—which reported a 29% decline in sales and orders for the fourth quarter and a net loss of $18.4 million for the year.

In addition, with the average sales price (ASP) of optical components dropping even as volumes begin to pick up, revenues are not keeping pace. According to Tom Hausken, senior analyst with Strategies Unlimited, the average price of semiconductor pump lasers has dropped from $1400 in 2000 to $600 today. The difference is more drastic in commodity products such as continuous-wave devices that sold for $2000 in 1999 and are now selling for $400 to $800, according to Hausken. Thus, while companies such as JDS Uniphase were reporting in late 2003 that volumes were up, their sales remain flat compared to previous quarters.

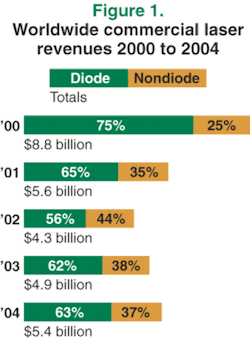

Our survey numbers indicate that, despite ongoing selected market and ASP contractions, a turnaround is in the works. For the first time in three years, overall laser-industry revenues increased, up 15% in 2003 over 2002—$4.9 billion in 2003 vs. $4.3 billion in 2002—despite a 2% decline in sales of nondiode lasers (see Fig. 1). The overall market is expected to gain another 9% (diodes 11%, nondiodes 7%) in 2004, reaching total sales of $5.4 billion.

Nondiode-lasers sales data for 2003 and 2004 are charted in detail by application and by type in Fig. 2 and Fig. 3. Nondiode-laser sales data by unit shipment and dollar revenues are shown in Tables 1 and 2, respectively. The corresponding charts and tables for diode lasers will appear next month. For an explanation of our methods, see "Where the numbers come from," p. 81. Note also that sales of fiber lasers and metal-vapor lasers are included in the "other" category.

The data presented in the tables are available with additional commentary in the Jan. 1 issue of Optoelectronics Report. The survey data will also be analyzed at the 18th annual Laser and Optoelectronics Marketplace Seminar on Jan. 26, which is held in conjunction with Photonics West (San Jose, CA) and is cosponsored by Laser Focus World and Strategies Unlimited. (For information about attending the seminar, call Lisa Gowern at 603-891-9267 or visit www.marketplaceseminar.com.)

The world at large

While the U.S. economy in general appears to be on the mend, the rest of the world is, for the most part, still struggling. In Europe, for example, 2003 proved to be a lackluster year for the laser and electro-optics industry. Not only is the telecom market still firmly in the doldrums, but other sectors have been hit as well. (Ed. Note: At year's end, three major European carriers—British Telecom, Deutsche Telekom, and Telefonica—were reporting better-than-expected financials, prompting some analysts to say that the EU telecom downturn appears to have bottomed out.) By necessity most telecom-related components suppliers have diversified, consolidated, or gone out of business, and analysts and industry executives seem to agree that a broad product line will be required for success once the market recovers.

Bookham Technologies (Abingdon, England), for example, has used its cash to consolidate and diversify; in the past year, Bookham acquired Nortel Networks Optical Components (NNOC) businesses, consolidated NNOC's Ottawa wafer fab facility into Bookham's Caswell facility in England, and established a much stronger presence in the United States through three California-based purchases: telecom components manufacturer Cierra Photonics (Santa Rosa, CA), optical module specialist Ignis Optics (San Jose, CA), and New Focus (San Jose, CA). Part of this strategy also includes diversifying into nontelecom areas, an idea that clearly appeals to investors. In October 2003, Bookham's share price rose to €2.4 (US$2.80), compared with a 12-month low of €0.9 (US$1.50).

As in the United States, the defense industry in Europe remains relatively healthy. Thales (Paris, France) reported consolidated revenues for the first half of 2003 at €4.56 million (US$5.34 million), a decrease of 3.5% on the first half of 2002. Aerospace business area revenues were down 2.3% on a like-for-like basis, reflecting the ongoing downturn in commercial aviation. However, the company claimed that avionics and simulation businesses continued to benefit from sustained military and helicopter markets. Defense business revenues dropped by only 1.6% on a like-for-like basis compared to the first half of 2002, which had seen a 21% rise compared to the same period in 2001.

On the positive side, the end of the year showed more positive signs throughout the European Union, with surviving companies feeling (much like their U.S. counterparts) that the worst may finally have passed. Although the European Union is projecting only 0.4% growth for 2003 and increased unemployment in 2004, it is committing billions of euros to several laser-related projects through its "Quick Start" program; it reportedly plans to invest up to €1 billion (US$1.23 billion) in laser research over the next three years as part of a €2 billion ($2.45 billion) project.

Turning to Asia, by far the hottest topic continues to be China. China's economy has grown rapidly in recent years; GDP increased an average 9.3% annually between 1989 and 2002, topping 8 trillion yuan (US$967.35 billion) in 2002. In addition, U.S. investment in China rose to $52.7 billion in 2002, the highest of any overseas investors. Both from a production and a consumption perspective, China currently represents the largest potential market for lasers and optoelectronics. Severak components companies—most notably Avanex (Fremont, CA)—have transferred much, if not all, of their manufacturing and assembly there. Spectra-Physics (Mountain View, CA)—which has had a presence in China since 1984—has established a subsidiary in Beijing to handle sales and service, with a satellite service in Shanghai focused on the industrial market. In addition, the China factor was seen as a bonus in the Bookham acquisition of New Focus; the latter has a fab facility in Shenzhen, China, that Bookham hopes will help lower its component manufacturing costs.4

Elsewhere in Asia, the Japanese economy appears to be on the rebound. The Tokyo stock exchange is on the rise, and if InterOpto 2003, held in Tokyo in July, was any indication, optical components suppliers in Japan are sensing, and responding to, a turnaround there.5 Among other things, the Japanese fiber-to-the-home market is booming, with between 300,000 and 400,000 subscribers already on board and fierce competition for service delivery between communications companies such as NTT and electric power utilities such as Tokyo Electric Power Company.

Other industry trends

As our projections for 2004 indicate, the struggles and streamlining this industry has gone through in recent years appear to be bearing fruit. Consolidation continued to be a strong trend throughout 2003.

Hand in hand with this trend has been the ongoing move toward outsourcing and streamlining supply chains, which in turn is leveraging the capabilities of more-established manufacturing processes. Part of this transition is being motivated by market forces and cost concerns, but it is also the result of the continued broadening of the market for lasers and optoelectronics, which in turn is pushing the commoditization of these devices.

"Today, we see lasers moving into many more mainstream applications that are transparent to most people but are creating new opportunities and placing extraordinary demands on laser products and the companies that provide them," said John Ambroseo, CEO of Coherent. "In order to move more and more into these broader markets, we need to generate consolidation. We need critical mass to drive engineering programs. Smaller companies have an important role to play, but taking photonics into more mainstream applications requires more resources."

One trend we highlighted last year has not played out as expected: homeland security. A year ago we noted that "the events of September 11 and the potential war in Iraq are also spurring increased government investment in advanced military technologies, including smart bombs, infrared guidance systems, and detectors." With the establishment of the U.S. Department of Homeland Security (DOHS) and the Bush Administration's commitment of $37 billion to homeland security initiatives in 2003, it appeared this market was ripe for lasers and optoelectronics, especially sensors and detectors.

A year later, however, few contract awards have been made, and the DOHS seems stuck in the process of deciding how to conduct its business. In fact, despite President George W. Bush's approval of the $30 billion Homeland Security Appropriations Act of 2004, more than 25% of federal homeland security activities remain unfunded.3 About the only sector of the commercial laser industry to see any real activity in this arena has been the use of IR lasers for target illumination although within the broader optoelectronics sector, much work is going on with respect to applying sensors and detectors for detection of bioagents, airborne pathogens, and other potentially hazardous substances. A consortium founded by the U.S. Defense Advanced Research Projects Agency, for example, will use $1.4 million over four years to develop semiconductor ultraviolet light sources, including light-emitting diodes (LEDs) and laser diodes, for the detection of bioagents such as anthrax. The consortium includes Kansas State University, Brown University, Cornell University, the University of California at Santa Barbara, the University of Texas at Austin, and various industrial partners.

Biotech is another market segment with a lot of apparent potential but not much clarity. As noted below, the instrumentation market is booming, due in large part to the growing interest in and adoption of laser-based devices for genomics, proteomics, and drug discovery. Blue lasers in the 400- to 500-nm range are finding a niche in portable cytometers, while diode lasers in the 1550-nm range are being investigated for near-infrared imaging applications. Other diode-laser and LED devices are in various stages of development for a wide range of optical diagnostics, particularly early cancer detection (for more on these technologies, see "Optical Diagnostics continue migration from benchtop to bedside," p. 130). But many laser companies—especially those coming out of telecom—are still struggling to find appropriate niches for their technologies and create or discover untapped markets in the biomedical field.

Finally, although this report only tracks laser sources, it is impossible not to mention the incredible growth the market for LED sources has experienced over the past 18 months. According to Strategies Unlimited, the high-brightness LED market grew 51% to $1.84 billion in 2002, and this trend is expected to continue, culminating in a $4.7 billion market by 2007 (see "Strategies in Light" at www.strategies-u.com). Here again, the adoption of this technology in an increasingly broad range of production-scale commercial applications—from automotive instrument panels and mobile phones to traffic signals, outdoor video screens, and highway signs—has contributed to what looks to be a vibrant market for the next several years.

Materials processing

The laser industry was banking on a turnaround in the semiconductor-equipment business in 2003, and while this market segment saw some positive signs, many companies were disappointed that it was not stronger. According to a survey published by the trade group SEMI (Semiconductor Equipment and Materials International; San Jose, CA) in July 2003, worldwide equipment orders were expected to increase 4% in 2003, from $19.8 billion in 2002 to $20.5 billion in 2003. The market is expected to really see a turnaround in 2004, growing 24% to $25.4 billion, according to SEMI.

"SEMI members see the long-awaited recovery materializing," said Stanley Myers, president and CEO of SEMI. "Following a two-year downturn in which the worldwide market declined about 60% from the historic levels of 2000, survey participants believe that the equipment market will begin a gradual broad-based recovery this year. Furthermore, they see double-digit growth in each of the next two years as chip makers install 300-mm facilities and gear up for advanced technologies."

Similarly, in November 2003 the Semiconductor Industry Association (SIA; San Jose, CA) said it expects global sales of semiconductors to increase nearly 16% in 2003 to $163 billion and another 19% in 2004 to $195 billion. According to the SIA's figures for semiconductor products, the optoelectronics market (which includes laser devices, image sensors, and products used in communications) is expected to increase 34.7% to $9.1 billion in sales and another 19% to $10.9 billion in 2004. In addition, according to SEMI, North American-based manufacturers of semiconductor equipment posted $871 million in orders in October 2003 and a book-to-bill ratio of 1.00, which means that the value of new orders equals the value of product billed for the period. The bookings figure is 12% higher than the revised September 2003 level of $778.8 million and 12% higher than the $775 million in orders posted in October 2002.

Laser systems suppliers are hoping this trend begins to translate into good news for them this year. Still suffering the effects of the downturn, Cymer (San Diego, CA) reported a net loss of $8.5 million on revenues of $64 million for the third quarter of 2003, compared to net income of $6.8 million on revenues of $84 million for the same quarter in 2002. However, in November 2003 Cymer president and CEO Bob Akins said the company was estimating a 5% to 10% increase in fourth-quarter revenues over third-quarter 2003 and a more robust recovery for the industry in the first half of 2004. Coherent subsidiary Lambda Physik, whose primary business is the sale of excimer lasers for semiconductor manufacturing and medical systems, is not yet feeling any turnaround effects, however; the company reported sales of $17.8 million in the fourth quarter of 2003, down 30% from the same quarter in 2002, and incoming orders of $15.7 million in Q4 2003, down 29% from orders received in the fourth quarter of 2002.

Total laser revenues in the semiconductor and microelectronics manufacturing sector in 2003 were down 18% from 2002. Excimer-laser sales for lithography represent the bulk of these revenues and are off by about 41% in units in 2003 (compared to 2002). Because the average sales price increased during the year as more-advanced units were being sold for lithography, the comparable revenue drop was only 25%. Overall sales for this sector are expected to gain a mere 3% in 2004.

Outside of semiconductor manufacturing, the industrial-laser market in 2003 took more twists and turns than a roller coaster at an amusement park. According to David Belforte, editor of Industrial Laser Solutions, going into 2003 the industry was mildly optimistic that the corner had been turned and that 2003 would be the transition year back to the pre-2000 double-digit growth levels. Late 2002 reports of shrinking order books in some markets sectors such as the auto industry, however, were a tip-off that the first half of 2003 was going to be a repeat of 2002, meaning spotty growth and unpredictability as far as placement for capital-equipment orders.

At the end of the second quarter of 2003, the bellwether annual report from industry leader (in terms of dollar volume) Trumpf (Ditzingen, Germany) showed the company managed only 2.5% growth, thanks mainly to laser sales. A survey of leading laser and system suppliers made at that time suggested that the transition horizon was going to slip into the first quarter of 2004. And sure enough, the most recent financials from public industrial-laser and systems suppliers are all positive, with most citing an expected growth year for 2004.

Looking at the numbers from the Laser Focus World and Industrial Laser Solutions surveys, the industrial laser sector experienced 11% growth in units sold compared to 2002 and 3% growth in revenues. Unit sales, worldwide, were sparked by sales of low-power solid-state and CO2 lasers for marking and engraving. The latter enjoyed a banner year as sales of sealed-off units for nonmetal working applications remained strong. But it takes a lot of low-power unit sales, with their attendant low selling price, to make up for deficits in the high-power market. And in 2003 the effect of increased global competition driving down unit prices was felt strongly by the industry leaders.

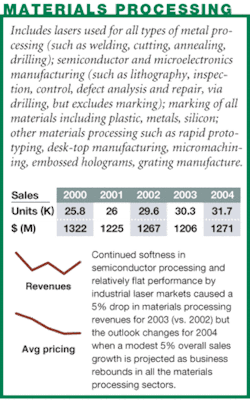

According to the Laser Focus World survey, laser sales for materials processing were rather mixed in 2003 compared to 2002. Total revenues in this market sector were $1.20 billion, down 5% from $1.27 billion in 2002, while unit sales rose slightly, from 30,501 in 2002 to 31,649 in 2003.

For 2004, industrial-laser systems suppliers expect to see 5% growth in unit sales and 3% growth in revenues, according to Belforte. This should translate into a 5% increase in components sales across the board for materials processing, with revenues reaching $1.28 billion. Several respondents to the Laser Focus World survey pointed to materials processing as having the most growth potential in 2004 with an increasingly significant contribution coming from fiber lasers. The potential for ultrafast lasers in materials processing also continues to intrigue many suppliers. In addition, the ongoing push toward miniaturization in electronics and optoelectronics is expanding the role for lasers in microelectronics processing (particularly drilling, scribing, marking, and etching) as dimensions and tolerances become more difficult for other machining techniques.

Basic research

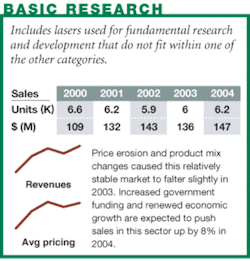

As has been the case for the last several years, the scientific market remained predictably stable during 2003. In fact, many of the companies selling lasers for research note that the relative stability of this sector has helped them weather the economic storm of the past two years. Part of the reason for this is that global research funding has benefited from various factors including defense and security monies and economic development activities, especially in Europe.

Although nondiode laser revenue growth was off by 5% in 2003 compared to 2002, it looks as if it will resume an upward trend again in 2004 with a sales gain of 8% for nondiode lasers. The downtick in 2003 resulted from several factors including product mix changes (flash-lamp-pumped solid-state lasers converting to diode-pumped solid-state devices, for example) and some general price erosion—a theme that runs through several of the market sectors this year. Nondiode unit sales in 2003 were 5999 compared to last year's forecast of 5950 (a 1% difference) and we expect units to increase by 3% to 6164 in 2004.

Medical equipment

Sales of medical laser equipment remained flat throughout 2003, reflecting the economic doldrums in most of the major world markets. With the bulk of the revenues in this market still depending on consumer-based applications in ophthalmology and dermatology, which patients must pay for out of pocket, physicians and equipment providers saw a continued decline in procedures such as vision correction and wrinkle removal. As a result, even some of the major players found 2003 a struggle.

Particularly hard-hit was Lumenis, which began implementing a major restructuring program in October 2003 that included laying off a quarter of its workforce (300 people); closing sites in Pleasanton, CA (the former Star Medical subsidiary acquired in Lumenis' purchase of Coherent Medical); Norwood, MA; Netanya, Israel; and Kristianstad, Sweden; streamlining offices in New York; and consolidating R&D operations to three sites in Santa Clara, CA, Salt Lake City, UT, and Yokneam, Isreal. The restructuring plan is intended to help the company deal with an outstanding debt of $210 million after posting losses for seven straight quarters in 2002 and 2003 and watching its stock price plunge from a high of nearly $25 per share in January 2002 to around $2 per share in November 2003.

Looking at the medical market as a whole, even no growth is better than negative growth, which is what the medical-laser business experienced in 2001 and 2002. According to Irving Arons, an independent consultant and contributing editor to Medical Laser Report who supplies our medical market numbers, the major suppliers of medical laser systems saw 0% growth in their revenues in 2003, up from –5% in 2002. Looking to 2004, Arons anticipates 10% growth year over year in sales among the major players, driven in large part by the general economic upturn in the United States and other parts of the world, plus the adoption of diagnostic wavefront systems for laser vision-correction surgery.

Not surprisingly, our numbers for the medical laser-components business show a parallel trend. Although last year we projected nondiode-laser sales growth of 11% in 2003, actual unit sales and revenues were off by 6%; we had expected revenues to reach $383 million in 2003, but they were actually only $326 million. Like Arons, however, we anticipate 10% growth in both unit sales and revenues for the medical laser-components business in 2004, with the increases coming across the board in most sectors of the ophthalmic and therapeutic business segments.

In fact, a handful of medical-laser-systems suppliers—most notably Laserscope, Candela, and Biolase—reported strong growth in sales and profits in the second half of 2003. Their success appears less as a result of improvements in the economy and more because of smart business strategies that take advantage of a changing marketplace and increasingly sophisticated customers who are more concerned with a product's capabilities and performance than technology for technology's sake.

Readers should note that many medical-systems manufacturers do not participate in our survey. To derive the laser source revenues reported here, we rely on Arons, who tracks medical-system end-user sales within this market sector. Revenue projections by Arons are based on medical-system sales to medical end-users—the laser is only one component of these sales. The numbers in our tables, however, are based on revenue estimates of the laser source itself. For more specific discussion of the medical market by laser type, see the January 2004 issue of Medical Laser Report.

Instrumentation

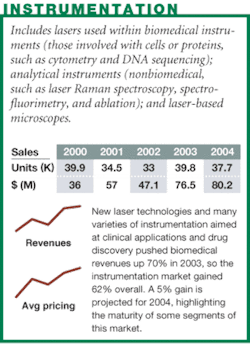

Although the market for lasers and other optical components for instrumentation remains relatively small, it still provides some excellent growth opportunities, according to Michael Tice, senior consultant with Strategic Directions International (SDi; Los Angeles, CA) and contributing editor of Instrument Business Outlook, published by SDi. Life-science instrumentation, including flow cytometers, DNA sequencers, microarray scanners, and other technologies, remains the fastest-growing area for laser-based instrumentation.

However, the demand from pharmaceutical and biotechnology companies is beginning to slacken. Capital expenditures from these industries rose at a blistering pace in the late 1990s but have subsided to a more moderate value. Nevertheless, Tice says the laser market for instruments for biological research should grow nearly 12% annually in the short term and that one of the most significant technologies, microarray scanners, continues to grow at nearly 20%. He notes that roughly 1700 scanners shipped in 2003, and most of them contained at least a pair of red and green lasers.

One continuing revolution in the instrumentation industry is the replacement of argon-ion lasers with solid-state blue-emitting devices. One fortunate consequence of this revolution is that the greater expense of the solid-state lasers helps grow instrumentation-market revenues, even as the unit sales show only moderate growth. Blue lasers can be found in many varieties of bioinstrumentation, where they are commonly used to stimulate fluorescent markers on DNA, proteins, or other biological molecules. This revolution is now reaching a mature stage of completion, though argon-ion lasers have not been, and will not be, totally replaced by solid-state lasers. Argon-ion lasers are still in demand, particularly for their other capabilities, such as UV emission.

Highlighting this revenue growth, the Laser Focus World survey of this segment shows a significant nondiode-laser revenue jump (62%) in 2003 compared to 2002, while unit growth was only 21%. Looking ahead to 2004, unit sales are expected to decline 5%, while revenues gain 5% to $80 million.

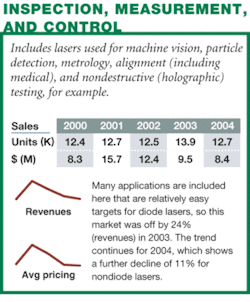

Inspection, measurement, and control

The dramatic miniaturization of electrical and optoelectrical circuits and the growing need for high-precision measurements of the shape of surfaces in manufacturing are a driving force in the laser-based inspection market. Confocal laser-scanning microscopy (and other forms of optical microscopy), for example, is used in the examination of semiconductor wafers as well as the reticles and masks used to print the circuits on them. Currently, solid-state (266 nm) or frequency-doubled argon-ion lasers (257 nm) are state-of-the-art sources for inspection; however, as semiconductor devices continue to shrink, shorter wavelengths will become necessary in the next few years. This trend is expected to help fuel double-digit growth in laser-based instrumentation.

For the time being, however, sales of nondiode lasers for inspection, measurement, and control are on the decline. While unit volumes actually increased 11% in 2003 (due to higher sales of HeNe lasers), revenues fell from $12.4 million in 2002 to $9.5 million in 2003 and are expected to continue to decline in 2004. This trend is due in part to the growing use of diode lasers for these applications (more on this next month). Hence overall laser sales in this market segment actually rose by 115% in 2003 to $44 million and are expected to remain essentially flat in 2004.

Image recording

The offset printing industry continues to adopt two main laser technologies: 830-nm thermal arrays and 410-nm violet diodes. According to Peter Dyson, editor of the Seybold Report (www.seyboldreports.com), until 2003 thermal dominated on large presses (eight-page and up) because photopolymer plate coatings capable of million-impression runs were available only for thermal wavelengths. In the small-press market, violet held sway because of lower capital costs.

But in 2003, Fuji released a violet-sensitive long-run photopolymer plate and the 30-mW diodes needed to expose it became widely available. Brazilian vendor IBF is expected to bring out its violet-polymer plate in early 2004, and the recent adoption of 40-mW sources will allow faster exposure of these plates. As a result, Dyson expects to see violet move into the large-format market.

Ultraviolet-laser systems are selling well to newspapers, but other segments of the publishing industry have shown little interest. Ultraviolet-sensitive plates are cheaper than violet or thermal plates, but UV-laser imagers are so expensive that only high page volume can justify them in terms of cost.

While total laser sales for the commercial printing sector increased 73% in 2003, this number includes diode as well as nondiode devices. We had estimated nondiode unit sales of 7643 in 2003, but our revised numbers were somewhat higher at 9831. In addition, revenues for nondiode lasers in this market were significantly higher than we had projected: $39 million vs. our estimate of $19.8 million (partially a reflection of improved detail on this market sector). While unit sales of nondiode lasers are expected to decline in 2004, to 9316, revenues are expected to jump again, reaching $49 million.

Military/aerospace

With the ongoing military actions in Iraq, Afghanistan, and other parts of the Middle East, plus the increased emphasis on homeland security in the United States and worldwide attention on potential terrorist activities, the market for lasers and optoelectronics in military and aerospace applications should show significant growth. We know anecdotally, for example, that sales of IR lasers for target designation have shown a significant increase. However, given the sensitive nature of many military applications, especially with worldwide tensions and concerns about terrorist attacks, it is difficult to pin down accurate descriptions of project awards and sales in this market.

As previously noted, the homeland-security market has not played out as expected, although certain technologies, such as LEDs, are being funded for bioagent sensing and detection applications. The DOHS is interested in other areas too. Commercial countermeasures for shoulder-fired missiles, for example, may include on-board lasers on civilian aircraft to disrupt missile sensors and steer missiles away from aircraft. The department reportedly is sifting through dozens of proposals to counter the threat of shoulder-fired missiles (also known as "man-portable air-defense systems") on U.S. commercial aircraft and is expected to make at least two contract awards for this application in January 2004 as part of the agency's two-year science and technology program.

Hand in hand with this is the increasing investment being made in environmental monitoring, both through government agencies such as NASA and in the private sector. World events over the last two years have shifted much of the focus in remote sensing to security and defense applications. But advances in optical sensors, laser-based LIDAR, and data-processing software are also expanding in land and sea studies that track the impact of humans on the global environment.6

Our survey numbers for military and aerospace reflect the lack of transparency in this sector. Nondiode unit sales for 2003 were only 615, up 14% from 2002; revenues gained 45%. Sales of nondiode lasers in this market are expected to grow another 21% in 2004. Diode-laser numbers are similarly inaccurate, so the overall market for this segment of about $34 million in 2004 is grossly understated.

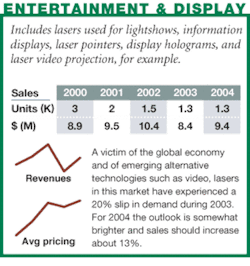

Entertainment and display

The entertainment and display market continues to suffer from the worldwide recession, although some of the larger companies are doing better than they were a year ago, due in part to their adoption of more broad-based approaches to the market. According to David Lytle, director of the International Laser Display Association (ILDA; Bradenton, FL) and editor of The Laserist, the most successful laser companies are those diversifying into complementary technologies, such as video and pyrotechnics, to become full-fledged multimedia and production companies. Another emerging trend is the use of laser projectors in conjunction with control systems that are DMX-compliant (the standard interface protocol used in the theater and entertainment industry) and "plug and play" with standard light boards. Some companies have also begun to offer their own computerized control systems to control any device used in a show, from lasers to fireworks, pyrotechnics, moving lights, smoke machines, and fans. "Companies are finding that they have to add value creatively beyond just the laser," Lytle said.

Worldwide, Lytle notes that Asia is currently the strongest growth market, both in terms of the manufacture of diode-pumped solid-state lasers used in entertainment and display and the growing China market for such applications as clubs, discos, and theme parks. On the technical side, entertainment firms continue to look for high-power solid-state blue lasers in the 450-nm range. According to Lytle, at the annual ILDA conference (Brussels, Belgium; November 2003) end users were anticipating the introduction of a 800-mW diode-pumped 457-nm laser from Omicron Laserage (Rodgau, Germany). Other companies continue to develop and introduce solid-state red/blue/green (RBG) diode lasers that produce white light; these devices are beginning to replace argon/krypton lasers in RGB video and other graphic applications.

Our numbers highlight the softness in this sector with nondiode-laser sales for entertainment and display applications off 20% ($8.3 million) in 2003. Looking ahead, the nondiode numbers for 2004 project a 13% increase in revenues, to $9.4 million. Total 2003 laser sales for this sector were $34 million (off 6% from 2002) and are expected remain essentially flat in 2004. As we will see next month, these latter numbers include tens of millions of diode lasers for use in laser pointers.

Other markets

The bulk of the remaining markets addressed in the Laser Focus World survey—including telecom, barcode scanning, sensing, data storage, and pump lasers—involve diode lasers and will be addressed in detail in the February 2004 issue of Laser Focus World. One exception here is in barcode scanning, where HeNe lasers are still used; however, sales of nondiode lasers for this application are on the decline (-10% in unit sales and -5% in revenues in 2003), a trend we anticipate will continue into 2004. The use of nondiode lasers for sensing applications, however, experienced a slight increase in 2003 (3% growth in units), although revenues fell 21% year over year ($13 million in 2003 vs. $16.2 million in 2002), a trend we expect to continue through 2004.

REFERENCES

- F. Norris, "Bloom is on the Economy," The New York Times (Nov. 8, 2003).

- "A flood of red ink," The Economist (Nov. 6, 2003).

- W. New, "Some homeland security activities remain unfunded," Government Executive Magazine (Nov. 10, 2003).

- K. Kincade, "Bookham to buy New Focus, Ignis," Optoelectronics Report (Oct. 1, 2003).

- C. Holton, Laser Focus World 39(9) 55 (September 2003).

- K. Kincade, Laser Focus World 39(6) 91 (June 2003).

Click here to download Worldwide commercial nondiode-laser sales 2003–2004 tables.

Where the numbers come from

The Laser Focus World Annual Review and Forecast of the Laser Marketplace is based on a worldwide survey of laser producers and covers 27 types of lasers and 20 applications. Information about diode-laser markets is provided by Strategies Unlimited (Mountain View, CA). The review is the only major survey of its kind in this industry whose results are made public.

For many, both inside and outside the industry, from private-sector investors to foreign and U.S. government bodies, this report is the only objective summary of major trends in our industry that is readily available. Part I takes a look at the overall market trends with more detail on nondiode lasers. Part II will be published in February and will cover the diode-laser marketplace.

Readers interested in the detailed results of both surveys will find them in the January 1 and February 1 editions of the Optoelectronics Report newsletter, published by Laser Focus World. A more extensive review of the data, with supporting commentary from market analysts, will be available to attendees at the Laser and Optoelectronics Marketplace Seminar, held in conjunction with Photonics West (San Jose, CA) on January 26. For more information see www.marketplaceseminar.com or call Lisa Gowern at 603-891-9267.

Collecting the data

We conducted our research and analysis for the Review and Forecast during October and November 2003. We asked manufacturers to provide an estimate of total worldwide market size (dollars and units) for 2003, based on year-to-date actual data, and a forecast for 2004. In addition to the information provided by the manufacturers, we also used data from other more narrowly focused market surveys, and we incorporated commentary provided by industry analysts who added insight into some of the markets.

Comparison with last year's numbers

Readers who compare last year's 2003 estimates with this year's restated 2003 numbers will note differences and occasional discontinuities in the numbers reported as compared to last year. In general, no attempt has been made to explain these differences in detail. We request "bottom-up" market estimates, and the respondents to our survey do vary from year to year—both in terms of the companies involved and the individuals—so variations in the results are inevitable. In addition, changes in market visibility occur as market shares change. Differences in the overall numbers for 2003 last year and for 2003 this year may also reflect whatever degree of optimism or pessimism was inherent in last year's forecast (see Laser Focus World, January 2003, p. 73). –SGA