Cognex surface inspection software identifies potential defects using statistical analysis

VisionPro Surface software for inspecting the surface of materials monitors the appearance of a material and uses statistical analysis to automatically identify potential defects and classify them into groups based on similarity in contrast, texture, and/or geometry. Automatic web-based reporting tools allow users to map, list,

and view defects.

Cognex

Natick, MA

www.cognex.com/vprosurface

-----

PRESS RELEASE

COGNEX INTRODUCES NEW SURFACE INSPECTION SOFTWARE

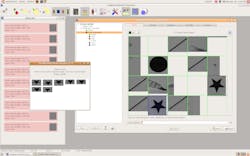

Cognex Corporation (NASDAQ: CGNX) today launched VisionPro® Surface, a vision software package for inspecting the surface of materials. VisionPro Surface combines a revolutionary new visual defect detection and classification technology with a simple user interface to enable accurate defect detection, classification, and surface texture assessment during the manufacturing process.

“VisionPro Surface makes the cost savings and quality improvements of automatic surface inspection available to production lines where more complex surface inspection solutions are not practical or economically viable,” said Dr. Markku Jaaskelainen, Executive Vice President and Business Unit Manager for Vision Software. “Manufacturers in industries such as solar energy, architectural glass, high-end plastics, material coating and other converting industries can achieve a quick return on investment by monitoring process efficiency, and identifying and eliminating defective material before it is shipped to customers.”

Unlike traditional surface inspection technologies that use signal processing to detect defects, VisionPro Surface works by monitoring the visual appearance of the material. Using statistical analysis, VisionPro Surface automatically identifies potential defects in the material’s surface, and classifies the defects into groups based on similarity in contrast, texture and/or geometry. During the training phase the user simply adjusts the system’s sensitivity for defect detection, and assigns names or values for defects to distinguish between different types. During production the system automatically classifies each defect according to the categories defined by the user.

VisionPro Surface comes with:

- Easy-to-use, self learning inspection software

- Point-and-click application configuration

- Visual self-learning defect classification tools

- Automatic web-based reporting tools that enable users to map, list, and view defects with just the push of a button.

Optional hardware components such as camera, I/O, lights and cabling can be purchased separately from Cognex, or from third party vendors.

VisionPro Surface is available now. More information about VisionPro Surface is available at www.cognex.com/vprosurface.