STEVE LANDAU

As we enter 2010, the acceptance of light-emitting-diode (LED) technology as a mainstream solution for illumination appears to be a done deal. Long a standard for signaling, signage, and automotive applications, LED solutions have only in the last year really became an obvious part of consumers' daily lives. Whether it's the retrofit bulb available from the local store, a lamp from a lighting retailer, or a streetlight along a boulevard or pathway, momentum is clearly with LED solutions (see Fig. 1).

Continued technology advances and innovation over the last ten years, particularly with respect to indium gallium nitride (InGaN) power LEDs (blue, green, cyan, and phosphor-converted white), has been the essential contributing factor. The first power LED, a LUXEON I delivering fewer than 20 lumens, was introduced in 2000. Now, power LEDs driven at 350 mA deliver light output, light density, and efficacy at a price that is motivating the global lighting industry and the energy infrastructure players to apply resources to the development of new illumination solutions.

The current state of LEDs

Global attention to energy-efficient solutions has risen dramatically in the last year. Significant improvement in LED efficacy has been expected and this year several LED manufacturers delivered, in volume, white power LEDs with stated efficacy in excess of 100 l/W and luminous flux of 100 lumens and above. Achieving this performance required a combination of improvements in epitaxial, phosphor, and packaging capabilities. These improvements were evidenced by higher light output, lower forward voltage and improved thermal management in the package. Although power LEDs have been called 1 W devices for quite some time, it's really only recently that regular production value made this a reality. With a drive current of 350 mA, forward voltage of 3 V, and typical lumens of 105 from a 1 mm2 chip, you're all but there: mA*Vf = watts or (.350)*(3.0) = 1.05.

The increase in light density achieved by LED manufacturers not only widens the variety of illumination applications for which LEDs are suitable, but also decreases the cost of light from LEDs. LEDs are semiconductor devices, and the cost of a semiconductor is essentially determined by its area. The more light produced by a given die area, the cheaper the light.

At this point, with white LEDs producing in excess of 100 lumens from the same chip size as a decade ago, the market is seeing costs decrease to about a penny per lumen, and the lumen-per-square-millimeter and lumen-per-package values increase to the point that solid-state lighting can deliver output, efficacy, and a lifecycle cost profile that can beat incandescent, fluorescent, and even high-power conventional streetlight lamps such as high-pressure sodium and mercury vapor.

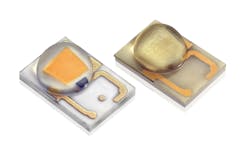

Another significant development was the release of phosphor-converted amber LEDs or PC Amber (see Fig. 2). Historically, amber (as well as red and red-orange) LEDs had a different chemical make-up from blue, cyan, green and white LEDs. In July, however, a PC Amber product was released that starts as a blue LED and converts the photons by passing them through a phosphor layer, like a white LED. But in PC Amber, instead of white light the result is a highly saturated amber wavelength of light. LUXEON PC Amber, for example, does this by using Thin Film Flip Chip technology and a Lumiramic phosphor plate. This approach provides a highly stable and robust solution without any bond wires in the light path, but there are other conversion methodologies that have been used as well.This approach has a real impact on the market because of the materials base. InGaN technology provides better reliability, better lumen maintenance, more light output, and lower lumen depreciation over time and temperature compared to the AlInGaP materials technology that conventional amber, red and red-orange LEDs use.

Widely used in automotive applications like rear combination lamps, turn signals, and brake lights, red and amber LEDs have had to be underdriven to allow for light losses and relatively poor lumen maintenance. With an InGaN base, however, the light output of amber LEDs can be improved four times, lumen maintenance is greatly increased, light output over temperature is increased, and color shift is greatly reduced. In illumination applications where amber is part of the mix, engineers can now manage similar drive current, temperature, and lumen maintenance profiles, thus simplifying the engineering process.

Expected LED performance

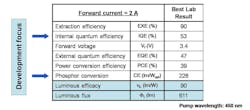

Even with current LED technology, adoption in some illumination applications is already widespread. But the development of LEDs is very far from being played out, and the prospects for improvements in performance give cause for optimistic forecasts that LEDs will replace traditional incandescent light sources in the foreseeable future (see table).The most recent indication of the road ahead came at the LEDs 2009 conference in October (San Diego, CA). Attendees were fortunate to hear directly from technology officers from companies including Philips Lumileds, Osram, Cree, and Nichia. What may be surprising is how well aligned the companies are in their expectation for the performance of white LEDs in the coming few years. It is widely agreed that white power LEDs will achieve the approximately 150 l/W performance level. George Craford of Philips Lumileds posed the question, "How achievable is a 1000 lumen, single-chip 1 x 1 mm2 LED that delivers 150 lm/W?" Using current "best lab results" he explained that through improvements in internal quantum efficiency (IQE) and phosphor conversion efficiency there is a real path to the performance levels in question.

Today, IQE in the lab is only about 53%. Craford proposes that IQE can be improved by a factor of 1.5x, and this will dramatically improve the output and efficacy of the finished LED. The U.S. Department of Energy is currently updating its LED roadmap: to date it has been fairly accurate, and it's expected that it will reflect the thinking presented by the aforementioned companies.

Correlated color temperature (CCT), color rendering and color binning have also been topics where future performance is expected to improve dramatically. Warm white LEDs in the 2700 K to 3200 K range—which represents the typical CCTs for incandescent and halogen lamps—are in the sweet spot for applications in shops, hotels and homes. Here too the scientists and experts agree that we will see continued improvement, particularly in flux. Binning, long the bane of the LED industry, has already improved with all major manufacturers adopting the ANSI binning scheme. Now each is working on ways to further simplify the binning process, making it easier for customers to select similarly performing LEDs time after time.

Although it is already possible for LED solutions to deliver system efficiencies comparable to fluorescent, and color profiles comparable to incandescent lamps, the cost profile remains high. While LEDs are seen by governments and legislators as an important element of the low-carbon future, the complete replacement of high-energy incandescent lamps by efficient LEDs is not commercially realistic today. Continued development to deliver higher light output at lower cost is critical if adoption rates and design innovation are to continue to accelerate.

Competing for the Prize

In September 2009, Philips Lighting submitted the first entry to the Department of Energy's L-Prize competition. The competition was established in an effort to speed development of a replacement for the 60 W incandescent light bulb. The requirements are that the LED retrofit bulb deliver 900 lumens, 90 l/W, 90+ CRI, use 10 W or less power, deliver warm white light, and have a long lifetime. Philips has accomplished this and it's expected that others will attempt to deliver similar solutions. But the opportunity to change lighting is upon us. The promise of LED lighting is real and can already be seen in light bulbs and on city streets, and on the Audi R8 sports car with LEDs in the headlamps. In these applications, LEDs deliver on their promise of power-efficiency, reliability, robustness, and flexibility.

STEVE LANDAU is director of marketing communications at Philips Lumileds, 370 W. Trimble Road, San Jose, CA 95131; e-mail: [email protected]; www.philipslumileds.com.