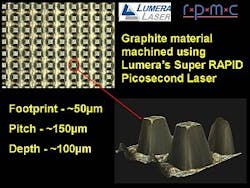

RAPID picosecond lasers are now offered with 50 W average power, greater than 10 ps pulsewidths, and repetition rates up to 2 MHz. The lasers are suitable for drilling or cutting thin materials to produce components that should not be subjected to heat. Pulses are so short that heat generated by the beam cannot migrate into heat-affected zones as can be the case with lasers that have longer pulsewidths; the result is a process known as cold micromachining that generates no burrs or splatter. The lasers are effective on any material generally less than 1 mm thick, and offer removal rates up to 30 mm3/min.

RPMC Lasers

O'Fallon, MO

[email protected]

------

PRESS RELEASE

Industrial 50W Picosecond Laser - increased power reduced price! A family of picosecond lasers is offered to manufacturers needing to drill or cut thin materials to produce components that should not be subjected to heat. The pulses of these RAPID lasers are so short that heat generated by the beam cannot migrate into heat-affected zones as can be the case with lasers that have longer pulsewidths; the result is a laser process known as cold micromachining that generates no burrs or splatter. These picosecond lasers are effective on any material generally under 1mm in thickness, and offer removal rates as high as 30 mm3 per minute. Users can micromachine any material with the same universal laser because this laser is effective on all materials used in semiconductor, electronics, solar cell, aerospace, automotive, medical, microfluidics, micromold technology etc. Our RAPID picosecond lasers are now offered with 50W average power with <10ps pulsewidths, and rep rates up to 2MHz. Also, we have a job shop that can perform laser processing as an alternative to the customer purchasing its own equipment.For more information, contact RPMC Lasers at 636 272 7227 or at [email protected].Sponsored Recommendations

Sponsored Recommendations

March 31, 2025

March 31, 2025

March 31, 2025

Voice your opinion!

Voice your opinion!