In an industry that moves at the speed of light, it is important to pause and recognize the many accomplishments coming from dedicated research and development teams. This is the real spirit behind our Innovators Awards program, where we encourage companies to submit their latest innovations for consideration.

The honorees will receive their awards at a January 2026 reception held in San Francisco between SPIE BiOS and Photonics West.

Now, meet our honorees...

PLATINUM-LEVEL HONOREES

Keysight

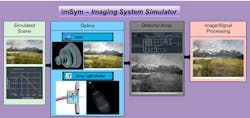

ImSym imaging system simulator

Developing a new imaging product often involves long development cycles and high risks due to reliance on physical prototypes to assess image quality, difficulties in managing system complexity, and barriers to collaborating between designers, manufacturers, OEMs, and partners. ImSym – Imaging System Simulator, the first commercial software for virtual prototyping of imaging systems, helps accelerate imaging design cycles, enhance team collaboration, mitigate development risks, and reduce costs by considering overall performance. By shifting the majority of imaging system development into virtual prototyping, ImSym facilitates a seamless collaboration across the development team, enables testing and validating the imaging chain before manufacturing, and helps new products get to market faster.

The imaging chain of digital optical image acquisition systems consists of a series of interdependent steps or links. Some of the significant links in the imaging chain include the scene, the action of the optics on the light exiting the scene, the action of the detector array and readout electronics in converting photons to electrons and then ultimately to digital counts, and the image and signal processing algorithms that act upon the detected digital counts.

Different specialists may be involved in different links in the imaging chain. For example, a lens design engineer is typically responsible for the design of the optics, while an engineer specializing in stray light analysis may be responsible for designing components that limit the propagation of stray light through the system. The digital imaging system may require the services of an engineer specializing in detector array use, design, or analysis, as well as an engineer specializing in image and signal processing.

Traditionally, optical system builders have relied on one or more physical prototypes to optimize and confirm imaging system performance. These physical prototypes can provide performance assurances, such as image quality assessment, but require significant build time and expenses. The traditional approach also makes it difficult to manage system complexity and imposes barriers to collaboration between specialists involved in the imaging systems development chain.

By providing a physics-based, end-to-end simulation platform, ImSym enables the validation of camera systems before manufacturing and during assembly. ImSym provides a quantitative model of an optical system. It models the entire imaging pipeline, including user-specified scenes, external light sources, optics, optomechanical parts and housing, image sensors, and customizable image signal processing (ISP) algorithms. System engineers and domain experts can simulate effects from all components before manufacturing.

ImSym enables tailored optimizations of any imaging system, facilitates team collaboration, and dramatically reduces development risk. With accuracy powered by industry-proven CODE V and LightTools optical design software and a quantitative end-to-end simulation flow, ImSym reduces the need for physical prototypes and delivers virtual prototyping that can accelerate imaging system design cycles at reduced cost.

ImSym also addresses the entire development cycle. First-order models can be used at the beginning stages of the optical imaging system design. As the subsystem models are matured to the conceptual, preliminary, and final design stages, each subsystem model can be updated in ImSym. Finally, measured subsystem performance models can replace design models to create a complete operational system model.

Light Conversion

HARPIA-LIGHT tabletop TA spectroscopy system

HARPIA-LIGHT is a tabletop transient absorption (TA) spectroscopy system, combining accessibility, versatility, and unparalleled performance in a compact, single-box design. It excels in providing exceptional measurement sensitivity, high temporal resolution, and broad spectral coverage. Despite its compact size, it houses an industrial-grade air-cooled femtosecond laser and a spectrograph with advanced, yet user-friendly data acquisition software. Its intuitive interface and streamlined workflow allow seamless operation, enabling users to save valuable time and effort.

For end users, HARPIA-LIGHT eliminates one of the key barriers to entering femtosecond spectroscopy: operational complexity. Traditionally, operating a TA system with femtosecond resolution required a dedicated laser engineer due to the optical alignment sensitivity, beam routing complexity, and software integration challenges. HARPIA-LIGHT resolves these issues through a Class 1 laser product in a compact, single-box design, featuring a fully enclosed optical setup, integrated control, and no requirement for an optical table. Users with minimal spectroscopy background can initiate measurements within minutes, as confirmed by early adopters like Prof. Kerzig’s group at JGU Mainz and Prof. Ludovic Troian-Gautier at Université Catholique de Louvain.

However, this simplicity does not come at the cost of capability. With its broad spectral coverage, high temporal resolution, and built-in femtosecond laser, users are now able to study dynamic processes such as solvation, exciton energy transfer, and photoreaction dynamics on femtosecond-to-nanosecond timescales—all without relying on external collaborators or complex infrastructure. In real terms, this speeds up research cycles, enabling iterative experimental design and data collection at the researcher’s own pace. It has already led to peer-reviewed results just months after delivery—validating its role as a turnkey solution for photochemistry and material science.

Overall, HARPIA-LIGHT is not just a product—it is an enabler of faster discoveries, broader access to ultrafast technologies, and reduced complexity for those building or operating research infrastructure. In doing so, it helps redefine what is possible—and who can participate—in the field of transient absorption spectroscopy.

PI (Physik Instrumente) L.P.

PINovAlign integrated photonics probe and test engine

The PINovAlign is a precision robotic alignment solution for integrated photonics probe and test at the wafer and chip scale. Developed to support the rapid growth of generative and agentic artificial intelligence (AI) and the adoption of photonic integrated circuits (PICs) across data center infrastructure, the PINovAlign represents a disruptive production scale solution for PIC probe and test at a critical time of technological growth and buildout.

The PINovAlign was designed and engineered from inception to address the unique demands of production-scale test of PICs critical to high-performance computing and networking solutions. Using a combination of mechanical control and algorithmic technologies, the PINovAlign is the most complete and capable precision robotic automated test solution commercially available, backed by critical and differentiated intellectual property.

At the core of the PINovAlign are disruptive patent-pending photonics probe and test algorithms that have proven through internal test and in the field to achieve signal finding alignments and optimization with orders-of-magnitude improvement over previous state-of-the-art methods (especially enabled in part by patent-pending algorithmic techniques called PILightning). These techniques are the first to efficiently support parallel signal finding of photonics inputs and outputs through an intermediate waveguide.

As a patent-pending combination of algorithms, nuanced details cannot be disclosed; however, significant improvement is achieved through a combination of higher-order multidimensional searches, machine learning optimization, and other novel search techniques with compute-efficient, parallel threaded processes working at high speed in harmony with real-time deterministic signal evaluation.

The algorithmic control of the precision robotic positioning system is carried in the core robot design, accommodating an innovative use of non-wearing direct-drive flex pivot on the fiber array unit (FAU) carrier platform. This optical-axis roll design is critical for common applications of integrated photonics test using loopback circuits. Additionally, onboard inverse and forward kinematics provide programmable virtual pivot to co-locate rotation about center of FAU or chip. These kinematic transforms leverage the real-time deterministic control that support in some cases millisecond-scale alignment and test measurements.

Provided in the complete solution is a precision multi-axis robot controller with embedded patent-pending algorithms onboard and a power meter/detector for an optoelectrical feedback loop required for PIC test.

GOLD-LEVEL HONOREES

Celestial AI

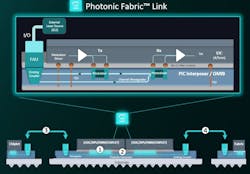

Photonic Fabric

Celestial AI’s Photonic Fabric represents a major leap forward in optical interconnects, fundamentally altering how high-performance systems are designed, integrated, and used, especially in AI infrastructure.

Photonic Fabric brings optical efficiency and the scale of light to mainstream chip architectures. Designers can overcome Moore’s Law limits in interconnect, integrators can assemble modular AI systems at massive scale, and end users benefit from faster, greener, and more cost-effective AI infrastructure, all without disruptive software changes.

For designers (chip/hardware architects):

- Triumph over the "Memory Wall." traditional electrical interconnects bottleneck data flow between memory and compute. Photonic Fabric uses light, achieving up to 25x more off-package bandwidth and 10x lower latency than copper or alternate optics.

- Design simplicity + power efficiency. By offloading data movement to photonics, designers can reallocate power from I/O to computation, enabling higher performance within fixed Thermal Design Power (TDP) budgets. Additionally, handling data optically simplifies system software and reduces design complexity.

- Seamless integration. Fully compatible with standards like HBM, HBM3E/4, CXL, PCIe, UCIe, and JEDEC, enabling drop-in optical integration without software rewrites.

For system integrators (OEMs, hyperscalers):

- Plug-and-play interconnect. Integration involves adding Photonic Fabric chiplets or IP into existing multi-die packaging flows—no need to overhaul design or rebuild software stacks.

- Modular scalability. Enables pooling and disaggregation of memory and compute across chiplets, packages, racks, and even data-center clusters. Switches and optical links (PFLink, PFSwitch, OMIB) allow flexible XPU-to-XPU architecture while preserving packaging standards.

- Ecosystem partnerships. Celestial AI partners with major packaging and memory players like Samsung, Broadcom, and specialized integrators, fueling a robust Photonic Fabric ecosystem.

For end users (hyperscalers and enterprises):

- Unmatched AI performance. Access to massively increased memory bandwidth at ultralow latency enables training and inference for large language models (LLMs) and recommendation engines with unprecedented scale and speed.

- Better resource efficiency. Facilitates memory disaggregation and pooling, enabling better utilization—especially important when unused memory resources can lead to wasted expense.

- Lower total cost of ownership (TCO). Reduced power consumption and fewer redundant chips translate into lower infrastructure and energy costs. Optics also support more efficient scaling—cutting capital and operational expenditures.

- Future-ready flexibility. Because it’s compatible with current protocols and infrastructure, adoption carries minimal disruption while offering easy upgrades as AI model sizes continue to grow.

HP Inc. & Adobe

HP Z Captis

The HP Z Captis is revolutionizing digital material capture by democratizing ultrahigh-fidelity, photometric, and polarimetric imaging previously accessible only through expensive, complex research setups. Designed with the creative professional in mind—fashion designers, game developers, architects, and industrial designers—Captis empowers users to scan real-world surfaces at up to 8K resolution using photometric stereo and polarization analysis. It delivers rich digital datasets that allow materials to be rendered with unprecedented realism across lighting and viewing conditions.

For designers, Captis solves a fundamental problem: how to digitize materials with physical accuracy, enabling photorealistic visualizations in AR/VR, digital product creation, and simulation workflows. Its integration with Adobe Substance 3D Sampler bridges the physical and virtual, streamlining workflows and reducing reliance on physical prototypes. The embedded NVIDIA Jetson AGX Xavier compute module accelerates image capture, on-device processing, and HDR material map generation, reducing full capture cycles from hours to under 10 minutes.

For systems integrators and OEMs, Captis is a platform, not just a product. Its containerized SDK enables AI and computer vision researchers to run custom models on-device, integrating Captis into bespoke pipelines for industrial inspection, digital twin generation, or advanced rendering.

For end users, Captis delivers a compact, dual-mode solution—Studio Mode for controlled environments and Explorer Mode for remote surface capture—allowing teams to bring the real world into the virtual domain with unmatched ease, speed, and fidelity.

By combining a 108MP mobile imager, software-defined capture states, ultrabright calibrated illumination, polarization control, and edge AI compute into one system, HP Z Captis represents a transformative leap for digital design and material creation. It redefines the boundaries of material realism, workflow speed, and democratized access to advanced capture technologies.

MassSpecpecD BV

Amsterdam Piezo Valve

Recent years have witnessed the development of advanced experimental techniques that strongly rely on the ability to bring molecular/material systems of interest into the gas phase for further applications. Many of these advanced applications employ techniques that are pulsed in nature and are often based on photonic instrumentations like for example high-repetition rate (ultrafast) lasers, free-electron lasers (FELs), or synchrotron radiation. Efficient use and analysis of molecular/material samples—sometimes only available in minute quantities—thus imposes the further requirement that samples ideally are brought in a pulsed way into the gas phase.

MassSpecpecD BV (Enschede, Netherlands) manufactures and markets the Amsterdam Piezo Valve (APV) for the production of strong pulsed atomic and molecular beams with duration as short as 20 µs. The APV is incorporated in state-of-the-art high-tech research instrumentation at universities and large-scale research laboratories like FEL facilities and synchrotrons located in Europe, the U.S., China, Japan, Korea, India, and South America. For instance, the novel SwissFEL research facility in Villingen has developed a Photon Arrival and Length Monitor (PALM) diagnostics device that measures the pulse length, and the arrival times of hard x-ray FEL pulses relative to a terahertz pulse and the laser from which it is generated. The PALM diagnostics equipment is based on the APV.

In many applications, the specifics of the nozzle exit determine the detailed characteristics of the supersonic flow like density, internal temperature, and geometry of expansion. For many current and future applications, it is highly desirable to match the geometry of the expansion to the typical geometry of a (focused) radiation beam (laser, FEL, or synchrotron). This will make it possible to have an optimal density and use of precious samples in the application and, therefore, optimal sensitivity. In collaboration with the group of Prof. Han Gardeniers at the MESA+/Nanolab of the University of Twente, we have recently developed a novel, microfabricated, rectangular de Laval nozzle that has been incorporated in the APV. This highly optimized nozzle is currently tested at the ELI-ALPS laboratory at Szeged, Hungary, in a joint collaboration with Max Born Institute Berlin, for an optimal top-hat gas beam profile for more-efficient high harmonic generation.

MKS Inc.

HybrYX DynaQuiet XY stage system

The Soft Isolation System option allows the XY stage system to operate at higher speed and acceleration (high dynamic) without sacrificing stability at the point of interest or inducing vibrations into the floor.

Many applications in wafer processing require high acceleration, high speed, and stability in location and velocity. Two of the most common are laser applications and metrology. The forces generated by accelerating and decelerating the mass of the wafer and wafer chuck/stage must be compensated or dampened to allow stability while processing the wafer. One of the common methods of achieving this goal is by using active counter mass damping (active compensation). This method balances the force with an equal and opposite force usually on the underside of the table/granite. While elegant in its concept, this method has the downsides of complexity and cost.

This solution takes a different direction by allowing the table/granite to move freely on elastomer mounting pads and compensate for the movement actively by adjusting the position of the wafer chuck/stage. The wafer processing tool is mounted separately from the movement system and sees the point of interest as stable, even as the stage and table are moving relative to each other. This method has the advantage of lower complexity/cost and dramatically reduces any vibration induced to the fab floor.

The patented Soft Isolation System is designed for applications such as optical lithography or wafer inspection that require fast movement from point-of-interest to point-of-interest, with minimal settle time while reducing vibration introduced to the production floor. Using a position control loop, the stage can actively compensate for movement by the granite and maintain a stable position at the point of interest. The system allows for high acceleration and throughput without inducing vibrations into the subfloor. The system also allows for extremely stable velocity control, which is very important, especially for laser applications.

Photonics Industries International

SN Sub-Nanosecond Series nanosecond laser

The SN Series from Photonics Industries is a breakthrough in high-power, sub-nanosecond laser technology, delivering precision, control, and performance in a compact, all-in-one package. Designed for the most demanding industrial and scientific applications, the SN Series offers tunable pulse widths from below 100 ps to 100 ns, average power up to 250 W, dual-head operation to 500 W, and pulse energies reaching 10 mJ. With true TEM00 beam quality and exceptional pulse-to-pulse stability, it offers the kind of consistency and flexibility that system integrators and advanced users need to solve complex processing challenges.

This laser platform fills a clear gap in the market. Where traditional nanosecond lasers fall short on precision and picosecond systems often lack the energy or power and pulse width flexibility for large-scale processing, the SN Series balances both with a versatile pulse engine. Whether it’s used for high-speed drilling, precision texturing, time-resolved diagnostics, or laser-induced fluorescence, the adjustable temporal profile and high energy density allow users to optimize interaction with a wide range of materials. The result is faster processing, cleaner edges, and reduced thermal damage.

One of the most valuable features of the SN Series is its integrated control over pulse timing. Pulse-on-Demand (POD) operation and Burst Mode are standard, allowing precise synchronization and shaping of pulse delivery. This enables users to match the pulse characteristics to each application without external modulators or complex setups. It streamlines integration into existing systems and increases throughput without sacrificing control.

The SN Series is built for real-world performance. Despite its high-power levels, it maintains a compact water-cooled design with no need for external control racks. It’s rugged enough for industrial environments yet refined for lab use, with intuitive software, TTL triggering, and Ethernet or RS232 interfaces. Beam pointing stability under 25 µrad and long-term power stability under 1% make it ideal for extended production runs or repeatable research applications.

To address the growing demand for versatility across industries like microelectronics, photonics packaging, and medical device manufacturing, the SN Series is also available with green and ultraviolet harmonic options. This makes it possible to process transparent and delicate materials with the same high performance and reliability. The ability to operate at 1064, 532, or 355 nm expands its utility without adding complexity to the setup.

The SN Series is not just a new product, it’s a platform that redefines what’s possible in ultrafast and high-energy laser processing. By consolidating power, precision, and configurability into a single device, Photonics Industries gives designers and system integrators a tool that shortens development cycles and improves end-product quality. From initial design to final deployment, the SN Series helps teams move faster and work more efficiently.

In a market that increasingly demands flexibility, reliability, and higher throughput, the SN Series stands out as an original and innovative solution. Its all-in-one format, pulse tuning range, and high beam quality open the door to new applications while simplifying integration for OEMs and end users. It represents a next-generation approach to laser design that matches the evolving needs of modern manufacturing and scientific exploration.

PRIMES GmbH

ScanFieldMonitor SFM 2D measurement system

To measure the beam parameters of laser beams within confined spaces of remote scanner systems, several established solutions exist. These include camera-based devices, scanning systems, and non-contact measurement methods using Rayleigh scattering. All of these approaches measure the laser beam under vertical incidence, centered beneath the scanner; however, they do not provide information regarding deflected beams or the scanner’s operational parameters.

To determine the positional deviation of the scanner, proprietary solutions are available for additive manufacturing (AM) machines, such as EOS SmartCal and Trumpf CalibrationLine. The aforementioned anodized aluminum plates offer positional information and some indication of the beam diameter (via the width of marked lines), but this system is cumbersome and lacks data on the beam during motion.

The most complete system to date is the award-winning PRIMES ScanFieldMonitor (SFM), which measures beam parameters as well as all scanner parameters, including position and velocity vectors. The compact SFM can be positioned anywhere within the scan field, but permits measurements at only one location at a time.

The SFM 2D overcomes all limitations of existing devices by extending the measurement principle of the SFM to a two-dimensional (2D) plane that covers the entire scan field. This modular system can be adapted to customer-specific scan field sizes and provides measurements at over 200 positions. Notably, the device can simultaneously measure at the center and up to 10 mm from the edges of the scan field, where the largest errors typically occur. While anodized aluminum plates require marking, measurement, and storage—processes that are time-consuming—the SFM 2D performs a full scan field calibration in approximately 20 seconds. Additionally, with the integration of a vertical motion unit, the device can record full caustic measurements at more than 200 positions simultaneously, generating a detailed map of beam waist locations across the entire scan field.

When compared to the working plane, this map reveals deviations, inclinations, or deflections of the focal plane. Consequently, the SFM 2D provides effortless three-dimensional (3D) measurement and calibration of the scanner system, which is particularly critical when pre-focusing systems are employed instead of f-theta lenses. Moreover, the caustic measurement map offers further insights into the optical system; for instance, misalignments or decentering in focusing optics may induce astigmatism when the laser beam is deflected. In production, the process runs vertically beneath the scanner as expected, but exhibits a significant decline in quality at the edges of the scan field. These issues are undetectable with other measurement devices. Furthermore, the SFM 2D allows for simultaneous measurements of multiple scanners, enabling the detection of stitching errors.

Not only the device’s size is tailored to the scanner system, but its software interface is designed for seamless communication between the scanner and the SFM 2D, greatly simplifying operation. Once configured, no expert knowledge is required—the device automatically communicates with the scanner and performs the calibration process fully autonomously when positioned within the machining area. Given its capabilities, robustness, and high level of integration, the SFM 2D is suitable for both laboratory and industrial applications, including service and quality assurance.

In today’s landscape, where extensive data on machine health is increasingly valuable and AI systems extract critical insights from this data, the SFM 2D can significantly contribute to the development of digital twins of laser-scanner systems.

None of the previously mentioned devices can match the range of functions offered by the SFM 2D.

SILVER-LEVEL HONOREES

Gentec Electro-Optics

PRONTO-250-EZ laser power meter

The PRONTO-250-EZ by Gentec-EO is a groundbreaking innovation in laser power measurement, designed specifically for harsh and demanding environments, such as laser-based manufacturing systems in which dust or contaminants can affect laser beam measurements. Launched at Photonics West 2025, this market-ready system is equipped with the revolutionary EZ absorber technology, which offers superior cleanability and reduced dust adherence due to its flat, nanoscale surface. This ensures consistent reliability and minimizes contamination-induced damage. The absorber also boasts high damage thresholds, making it suitable for both continuous-wave (CW) and pulsed lasers in the visible to near-infrared (NIR) spectrum.

Compact and portable, the PRONTO-250-EZ features a user-friendly touchscreen interface and supports three calibration options, catering to diverse laser applications. It measures laser power from 0.5 W to 250 W with exceptional accuracy and durability.

Targeted at professionals in industrial, medical, and research sectors, the PRONTO-250-EZ has already garnered interest from key players in the laser industry. Its operational efficiency, environmental resilience, and practical benefits make it a standout innovation.

The PRONTO 250 EZ redefines portable laser power measurement by centering on its groundbreaking EZ absorber—a flat, nanoscale surface engineered for ultralow reflectance and exceptionally high damage thresholds in both CW and pulsed infrared (IR) lasers.

Superior cleanability and uptime. The EZ absorber’s ultrasmooth finish prevents dust from adhering, so technicians can restore full performance with a simple wipe or air jet, eliminating downtime for sensor swaps or protective windows. Maintenance crews in marking, engraving, welding, and other harsh environments gain back critical production hours and avoid costly service calls.

Enhanced durability in the field. Thanks to its high damage threshold, the EZ absorber withstands up to 250-W average power (248 nm to 2.5 µm) and optional 10.6-µm CO2 calibration without added protective layers. This resilience makes the PRONTO 250 EZ indispensable for field repair and system validation on high-power laser installations, where robustness directly translates to fewer interruptions and lower TCO.

Uncompromising value. Despite these breakthrough benefits, the PRONTO 250 EZ is priced identically to the previous H-absorber PRONTO 250 FLEX, delivering unmatched ROI. Organizations can upgrade their entire fleet without additional capex, ensuring every service technician and end user has access to the latest absorber technology at no extra cost.

Streamlined system design, maintenance, and integration. System architects and design engineers leverage the PRONTO 250 EZ’s pocket-sized (59 × 181 × 17-mm) form factor, integrated mounting holes, and modular calibration options (“Y” for visible/NIR, “C” for CO2, “E” for energy) to build compact, purpose-built test fixtures. The familiar USB and serial command interfaces further simplify embedding the probe into automated control loops and portable diagnostic kits.

By marrying novel absorber science with field-ready portability, the PRONTO 250 EZ empowers designers to create sleeker, maintenance-free measurement nodes; maintenance technicians to perform rapid, reliable calibrations and troubleshooting without downtime; and end users to maintain consistent process quality and safety in the most demanding laser applications—all while enjoying a best-in-class total cost of ownership.

IDEX Health & Science

BrightLine 2.0 Semrock optical filters

The release of Semrock BrightLine 2.0 filter sets from IDEX Health & Science marks a significant leap forward in fluorescence imaging. This isn’t just an update; it's a complete redesign that addresses critical market needs, leverages cutting-edge technology, and boosts productivity.

Innovation and strategic redesign. BrightLine 2.0 is a strategic overhaul. Individual filter spectral specifications and production processes have been meticulously aligned with standardized family set requirements, ensuring cohesive performance previously unattainable at this price point. A key innovation is the use of the latest all-thin-film, hard-coated construction technologies which enable superior performance and reliability. These filters are also optimized for modern light sources, maximizing efficiency with contemporary illumination methods.

Crucial advancements in BrightLine 2.0 are the precise edge-placement and steeper edge capabilities enabled by advances in coating processes and metrology capabilities. These capabilities are particularly advantageous for short Stokes shift fluorophores, where maximizing the fluorescence signal is vital for accurate and clear imaging. The ability to create narrow spectral transitions from high transmission to deep blocking allows for the most efficient separation of excitation and emission light, preventing unwanted bleed-through and ensuring the detection of faint signals.

Addressing market needs with accessibility. Perhaps the most impactful aspect of BrightLine 2.0 is its ability to deliver enhanced performance at an accessible price. At just $895 for BrightLine 2.0 sets, and an even more competitive $545 for BrightLine Basic™ sets, IDEX Health & Science has made high-quality, reliable optical filters more attainable. This addresses a critical market gap, making cutting-edge research and diagnostics accessible to a broader range of customers.

Beyond cost, BrightLine offers clear and consistent specifications, simplifying product discovery and selection. This benefits designers and integrators who need to quickly identify the right filters. BrightLine Basic further caters to cost-conscious customers in applications where reliable performance is essential but stringent specifications are less critical. This tiered solution effectively addresses diverse market demands. Ultimately, the precise optimization of component spectral specifications for specific fluorophore excitation and emission ensures superior signal-to-noise ratios and brighter images, crucial for sensitive applications like confocal microscopy.

Boosting productivity and leveraging novel technology. For end users, superior signal-to-noise ratios and brighter images mean clearer data, potentially faster acquisition times, and more reliable results, accelerating research and improving diagnostic efficiency. BrightLine 2.0’s sharp, steep edges minimize crosstalk between excitation and emission, leading to a purer signal and enhanced image clarity, which is paramount for quantitative analysis.

The filters provide maximized contrast through deep complementary blocking (OD 8 – OD 10). This unique feature is supported by Semrock's proprietary KolaDeep™ Spectral Measurement System, guaranteeing consistent and exceptional performance leading to higher image quality. For designers and systems integrators, the simplified selection process streamlines development cycles.

BrightLine 2.0’s reliable performance further contributes to productivity. Semrock filters are renowned for their hard, thin-film sputtered coatings, ensuring durability and consistent performance over extended periods. This reduces downtime for end users and provides critical reliability for OEM manufacturers.

These filter sets leverage truly novel technologies. Beyond the proprietary KolaDeep™ system, the all-thin-film, hard-coated construction sets a new standard for reliability, ensuring filters do not degrade or "burn out." The precise edge placement and steeper edges specifically address the challenges of modern fluorophores, allowing researchers to fully exploit their spectral properties and achieve optimal performance.

In summary, the Semrock BrightLine 2.0 filter sets represent a comprehensive leap forward. They deliver enhanced performance and reliability through advanced coating technologies, precise edge control, and optimized spectral performance, addressing market demands for cost-effective and clearly specified solutions. This empowers users to achieve brighter, clearer, and more reliable fluorescence images, ultimately accelerating scientific discovery and improving diagnostic capabilities.

OZ Optics Ltd.

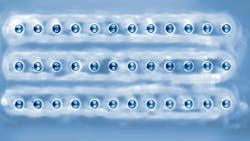

2D Fiber Matrix Array (2D FMA) assemblies

OZ Optics offers a wide range of customizable 2D Fiber Matrix Array (FMA) assemblies, built using various types of optical fibers—including single-mode, multimode, polarization-maintaining (PM), and specialty fibers—at customer-specified lengths. These advanced 2D fiber-optic assemblies enable precise positioning of thousands of channels in both the X and Y directions simultaneously, with no crosstalk between fibers.

Leveraging its proven expertise in 1D V-Groove fiber positioning technology, OZ achieves exceptional alignment and end-face polishing, ensuring superior optical performance and tight length tolerances. We guarantee precise pigtail output lengths, making these assemblies ideally suited for interferometric and other high-precision optical applications.

A key advantage of the 2D FMA technology is the ability to mix different types of fibers within a single array, offering maximum flexibility for complex system requirements. PM fibers help maintain consistent polarization states throughout the system, minimizing polarization dependent losses (PDL) and polarization mode dispersion (PMD). This level of polarization control is essential for enabling high-speed optical systems to ever-evolving next-generation coherent detection platforms.

OZ Optics’ 2D FMA assemblies are designed and manufactured for high-performance optical fiber subsystems and module integration. Building on extensive experience with 1D V-Groove Fiber Arrays—a solution widely adopted by the optical community— OZ offers a robust platform to meet the growing demand for high-density optical transmission across various applications, including optical cross-connections, biomedical imaging, spectroscopy, and astronomy.

The 2D FMA assemblies utilize a range of PM fibers with high polarization extinction ratios (PER) of up to 30 dB. A unique feature of OZ Optics’ 2D FMA is its ability to accommodate a mix of different fiber types within a single array, offering exceptional versatility and adaptability for diverse application needs.

PhotoniCore Technologies Co. Ltd.

(9+1)×1 side pump combiner

All-fiber taper-fused (N+1) ×1 pump/signal combiners have been widely used in high-power fiber laser/amplifier systems. There are two types of (N+1) ×1 combiners: end-pumped and side-pumped. The former is to inject pump light through the end of double-clad fiber (DCF), while the latter is to inject pump light through the side of DCF. Thanks to its non-interruptive nature of the signal path, the side-pump/signal combiner (SPC) has shown advantages in many aspects, especially in backward pumping and intracavity pumping schemes. However, due to the challenge of manufacturing SPCs for N>2, only (1+1) ×1 and (2+1) ×1 SPCs are currently available in the market. Recently, PhotoniCore Technologies (PCT) has filled the gap and successfully produced SPCs with large N (up to N=9). The high quality and stable performance of PCT’s SPC products indicate their great potential in the field of high-power fiber lasers.

Its pump coupling efficiency is typically over 95% and its signal insertion loss is less than 0.2 dB. Also, the N number as well as pump fiber and signal fiber parameters can be customized.

The (9+1) ×1 SPC was tested for pump power handling. Its temperature slope vs. laser power is as low as 0.0133°C/W, highlighting its excellent thermal stability. This will ensure reliable performance and reduced maintenance in precision applications such as cutting and welding.

Again, owing to its uninterrupted signal path, (9+1) ×1 SPC itself has almost no impact on the laser beam quality. Therefore, it can be adopted in high-power fiber laser systems that require excellent beam quality (low M2). Superior beam quality is essential for higher power density, faster processing speeds, less energy loss and minimal thermal effects, improving efficiency and precision in applications such as cutting and welding.

The (9+1) ×1 SPC exhibits high isolation against reverse light, thus protecting the pump diode sources: 1) When any signal light propagates along the DCF toward the pump diodes (in backward-pumping configuration), the average isolation of the nine pump ports is as high as 40.0 dB; 2) When any pump light propagates along the DCF toward the pump diodes (in bi-directional pumping configuration), the average isolation of the nine pump ports is 12.8 dB. Such high isolations minimize the interference of reverse light on pump diodes, ensuring high stability of the system, making the SPC an ideal choice for integration into high-power fiber laser systems.

In summary, PCT's (9+1) ×1 SPC features high reliability, low loss, and excellent stability, enabling designers and system integrators to seamlessly integrate it into the systems. With its high pump coupling efficiency, low temperature slope, minimal beam quality degradation, and excellent isolation, it ensures consistent performance in demanding applications such as industrial cutting, precision micromachining, welding, 3D printing, surface treatment, battery production, and aerospace manufacturing. These features enhance system stability, extend service life, and minimize maintenance requirements, thereby simplifying system design. The energy-saving characteristics of the SPC reduce operating costs and environmental impact, making it ideal for sustainable manufacturing. Its rugged design withstands harsh industrial environments, ensuring long-term reliability and cost savings. For end users, this means a cost-effective, durable, and high-performance laser system with a simplified architecture that significantly improves productivity and operational efficiency.

Santec AOC

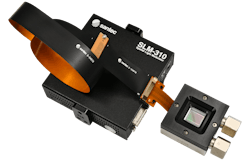

SLM-310 high-power spatial light modulator

The SLM-310 high-power spatial light modulator (SLM) from Santec AOC represents a significant advancement for designers, systems integrators, and end users involved in high-power near-infrared laser processing. Engineered to handle 1 kW-class laser power in the 1-µm wavelength band, this liquid-crystal-on-silicon (LCOS)-based SLM empowers professionals to adopt advanced laser techniques previously limited by the constraints of galvanometer scanner systems.

For designers, the SLM-310 opens new avenues for implementing beam shaping and multipoint irradiation strategies in industrial systems. It supports innovative system architecture for laser welding, drilling, cutting, and metal 3D printing.

Systems integrators benefit from the SLM-310’s compact form factor, high reliability, and compatibility with existing industrial laser setups. Its integration leads to enhanced machine performance, reduced thermal impact on materials, and greater precision.

End users, particularly in additive manufacturing and precision processing sectors, gain access to next-generation processing capabilities that offer increased efficiency, finer resolution, and improved material outcomes. The SLM-310 enables controlled, programmable laser shaping at high power—resulting in shorter cycle times, greater consistency, and higher product quality.

SemiNex Corp.

High-power narrow-linewidth external cavity laser (ECL)

SemiNex is excited to announce the launch of its high-power, narrow-linewidth external cavity laser (ECL) with single frequency capable of achieving above 200 mW out of fiber and <3-kHz Lorentzian linewidth. This high performance is critical for optical networks, frequency-modulated continuous-wave (FMCW) LiDAR, aerospace systems, and precision industrial sensing applications.

SemiNex’s proprietary high-power gain chip and semiconductor optical amplifier (SOA) are incorporated with a photonic integrated circuit (PIC) in a single fiber package, forming an external cavity architecture that enables tight optical feedback and very narrow linewidth with high output power. Outperforming distributed feedback (DFB) lasers at critical wavelengths such as 1310 nm and 1550 nm, ECL easily reaches fiber-coupled output powers >200 mW and a <3 kHz Lorentzian linewidth with low relative intensity noise (RIN) and excellent side mode suppression ratio (SMSR). The high-power performance firmly lands SemiNex’s ECLs in a tier above alternative sources, where high power typically is difficult to achieve in similar packages. SemiNex’s design is offered in both C- and O-band operating wavelength ranges or can be customized to fit unique center wavelengths for specific applications.

The high-power ECL module is constructed in a standard 14-pin butterfly fiber package, allowing for a smooth transition drop-in integration for the ease of system stabilization and optical alignment. SemiNex’s ECLs possess long-term stability and reliability benefited from the robustness and long lifetime of the SOA and gain chips. This makes it ideal for the rapidly expanding applications in coherent LiDAR, quantum sensing, industrial metrology, and aerospace-grade navigation.

BRONZE-LEVEL HONOREES

Advanced Fiber Resources (Zhuhai) Ltd.

PurePath TG-CPS

The PurePath TG-CPS streamlines the design and integration of high-power fiber laser systems by combining three key functions, which are the output coupler fiber Bragg grating (OC FBG), Raman scattering suppressor FBG (RSS FBG), and cladding power stripper (CPS) into one compact packaged component.

For fiber laser designers, this integration simplifies system architecture. Instead of managing multiple discrete components, a single device performs all three critical optical functions. This reduces design time, alignment complexity, and the number of potential failure points. This one single fiber and splicing joints-free design minimizes insertion loss and improves thermal stability, while the compact size supports miniaturization and higher integration density.

System integrators benefit from easier assembly, fewer fiber splicing joints, and reduced system loss. The short fiber length, combined with the integrated RSS FBG, raises the Raman threshold, allowing for higher power operation in forward-pumped lasers. The device supports up to 3-kW CW laser output, with <0.3-dB insertion loss and 300-W cladding laser power stripping performance, which is offering robust, reliable operation even under harsh conditions.

End users experience improved performance and durability. The integrated design ensures purer signal output by effectively removing residual pump light, back-reflection, and stimulated Raman scattering. In master oscillator power amplifier (MOPA) systems, it enhances seed signal purity and protects upstream components, extending overall system life and reducing maintenance needs.

OZ Optics Ltd.

In-line multimode fiber speckle homogenizer

Unlike traditional speckle reduction systems that often require separate drivers, this product integrates both the speckle homogenizer and driver electronics into a single compact enclosure. Its plug-and-play functionality eliminates complex setup procedures, significantly reducing integration time and risk of misalignment. Additionally, the system is customizable to meet specific optical requirements, including wavelength, power handling, and fiber compatibility, providing unmatched flexibility for a wide range of OEM and research applications. This product is specifically designed for the bioanalytical market, offering a shift from single-mode lasers and fibers to multimode configurations, paired with the multimode speckle homogenizer. It is ideal for applications that require broad wavelength coverage, from UV to NIR, making it a perfect fit for bioanalytical instruments, flow cytometry, and other high-performance imaging systems.

Key features and advantages include:

- Averages modal noise. Significantly reduces speckle by averaging modal noise, improving optical performance.

- Maximizes optical performance and reliability. Reduces speckle to ensure consistent and reliable output with enhanced image quality.

- Small form factor. Designed to fit into space-constrained applications, making it versatile and easy to integrate.

- No optical loss. Ensures the integrity of the optical signal as in-line fiber device with zero optical loss.

As optical systems evolve to meet increasing demands for resolution, speed, and spectral range, the in-line multimode fiber speckle homogenizer provides a scalable solution that grows with your application. Its plug-and-play architecture, combined with robust mechanical and optical design, makes it ideal for both OEM integration and laboratory use.

Whether you are developing the next generation of diagnostic instruments, high-speed imaging platforms, or precision measurement tools, this homogenizer will help you achieve the uniform illumination necessary for optimal system performance.

Suzhou Everbright Photonics Co. Ltd.

200-W, 1470-nm fiber-coupled diode laser

Relying on its independent and complete vertical industrial chain platform and based on the 1470-nm semiconductor laser chips independently developed and mass-produced by Everbright Photonics, the company has taken the lead globally in launching fully independent high-power, 1470-nm fiber-coupled semiconductor lasers, combined with advanced automated optical packaging and process platforms. These lasers can be widely applied in agriculture, medical treatment, industry, and other fields. The products feature high reliability, high efficiency, long service life, and a compact structure, ensuring convenience and safety in diverse applications.

About the Author

Peter Fretty

Market Leader, Digital Infrastructure

Peter Fretty began his role as the Market Leader, Digital Infrastructure in September 2024. He also serves as Group Editorial Director for Laser Focus World and Vision Systems Design, and previously served as Editor in Chief of Laser Focus World from October 2021 to June 2023. Prior to that, he was Technology Editor for IndustryWeek for two years.

As a highly experienced journalist, he has regularly covered advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.