Dicing GaAs wafers

Silicon has dominated the semiconductor wafer market for more than three decades. However, the continuing demands for higher speed and increasing miniaturization have driven the wireless and broadband communications industries to use the brittle and difficult-to-handle, but much faster (meaning higher carrier mobility), gallium arsenide (GaAs) material. Most of the big players in the semiconductor market have turned their production in this direction. As a result, $3 billion, of the $119 billion integrated circuits produced in 2001, was accounted for by this compound. According to a study by Kline & Company Inc., a leading business consulting firm, GaAs accounts for almost three quarters of the total production of compound semiconductors for the last few years.

Decreasing the chip size below 500 µm requires using wafers thinner than 100 µm. The use of GaAs wafers, which might be as thin as 25 µm, creates problems when they reach the last level of the production chain—chip singulation. Because GaAs is very brittle and fragile, even improved saw methods using resinoid blades do not provide the desired high cutting speed, production rate and yield.

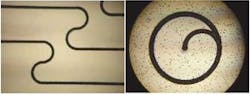

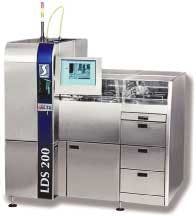

Use of a Synova Laser MicroJet appreciably increases the speed and kerf quality of GaAs wafer dicing (see Figure 1). Moreover, it allows free-shape cutting, which is not possible with conventional saw techniques (see Figure 2). The Laser Dicing Machine LDS-200, shown in Figure 3, has been specifically designed for the dicing of semiconductor wafers because of its high speed and constant cutting quality, which has attracted the attention of the GaAs wafers manufacturers. The increasing interest in the waterjet-guided laser technology is supported by the fact that about 40 percent of the samples processed with the laser MicroJet at The Gem City Engineering Co. (GCE - Dayton, OH), were GaAs or compound semiconductor wafers. GCE is the exclusive representative and distributor of Synova for North and South America and its laboratory of laser applications is especially equipped for processing of GaAs and other compound semiconductor samples.

Manufacturing and processing of compound semiconductors, especially GaAs, reveals serious industrial safety concerns because of the hazardous chemical compounds found in certain processes.

GaAs and safety

GaAs crystal compounds of 51.8 wt% arsenic, an acute toxic material, are considered a hazardous material and potential carcinogen by the Occupational Health & Safety Administration (OSHA). Therefore, cutting of GaAs wafers with lasers, in particular with the laser MicroJet, raises questions about the personnel and environmental safety of the process. The interaction of a powerful laser beam with matter leads to material ablation at high temperatures. According to the Material Safety Data Sheet (MSDS) of GaAs, the product will thermally decompose above 480o C emitting toxic vapors of arsenic and oxides of arsenic. Moreover, reaction with acid and/or steam may release arsine gas, which is the most acutely toxic form of arsenic.

Information about the potential hazards of processing GaAs with the waterjet-guided laser was not available due to the novelty of the technique. And, it was not possible to make conclusive predictions about the potential contamination, because the physics of interaction of a pulsed laser beam confined in a waterjet with matter is not completely clear yet. The scanty information available from some GaAs manufacturers could not be applied directly because of the difference between the manufacturing deposition techniques and the MicroJet cutting process. For the same reason, the data for cutting GaAs wafers with conventional saws was not helpful either.

Trial runs with MicroJet

A trial run of non-stop GaAs wafer dicing, for a few hours, was considered as a solution for gathering experimental data. The goal of the test was to clarify, qualitatively and quantitatively, the potential hazards in real working time, and on this base to estimate the precautions that should be considered during normal multi-shift work.

The trial run used the LDS-200 machine shown in Figure 3. During the test wastewater was collected in a vessel that was disposed of as a hazardous material. The machine was equipped with a HEPA exhaust system, the ventilation system of the laser room was shut down, all supply and exhaust openings were sealed and access to the room was restricted. The machine operator was wearing a protective suit, rubber gloves, a respirator with HEPA filter and an adjustable flow airline hood supplying fresh air from a breather box.

Sampling and analysis summary

The presence of arsine gas was monitored by three digital gas detectors with sensitivity from 0 to 1000 PPB. The airborne arsenic was monitored by five detectors (method reference #NIOSH 7900), as a sample was collected within the operator's breathing zone. The level of contamination by As and GaAs particles was evaluated by seven wipe samples taken from the cutting chamber and the room floor and walls immediately after the trial run. The level of contamination of the wastewater was evaluated on the basis of samples taken every 15 minutes directly from the tank of the machine and analyzed later by methods EPA 200.8 and EPA 200.2. The operator was tested for arsenic exposure the day before and after the GaAs trial run. Details about the monitoring conditions and sample analysis, as well as a table with the test results, can be found in a paper by the same author, "Safely Dicing GaAs Wafers with Lasers," published in the Technical Digest of ISA Safety Symposium, 2003, Houston, TX, vol. 438, pp. 175-183.

The most important result from this experiment was that Arsine gas was not detected. Briefly, the results show the highest concentration of airborne arsenic was measured inside the cutting chamber, while the detectors outside the machine and those placed on the operator measured 2.5 times lower concentration than the OSHA PEL. The level of arsenic in the human body was reported to be twice lower than the OSHA carcinogen level. The most polluted, as expected, was the wastewater.

The results of the GaAs trial can be summarized as follows:

- No arsine gas was detected inside and outside the cutting chamber.

- The main concerns should be the proper handling and recycling of the wastewater.

- An exhaust system with high-efficiency dust/mist filtration, arsenic filter and wet post-cleaning of equipment and facility, are definitely required.

- Full personal protection - rubber or plastic gloves, HEPA respiratory filter, glasses or protective shield—is necessary.

- The laser MicroJet technology might provide safe working conditions, if the aforementioned precautionary measures are fulfilled.

Dr. Natalia Dushkina is manager of the Laser Applications Laboratory at The Gem City Engineering Co., Dayton, OH. Contact her at Tel. (937) 221-5275 or e-mail [email protected].