Processing with ultrashort-pulse lasers

Kaiserslautern, Germany—Pico- or femtosecond, just how short can they pulse an industrial solid-state laser and still get sufficient power density and pulse repetition rate to accomplish cost-effective laser processing in a factory environment? ILS has been puzzling over this question for some time as we recognize that the next wave of high-growth rate applications will likely come from the field of microprocessing.

Femtosecond lasers have been shown to produce non-thermal response or "cold" processing results, specifically in micron-level thickness materials, albeit not without some unresolved productivity issues. In a recent survey of ultrafast-pulse processing proponents we learned that a couple of the most promising industrial applications, stent cutting and microhole drilling, can probably be accomplished by picosecond lasers with equivalent results to femtosecond lasers, yet with faster processing rates and at a significantly lower equipment cost.

Not to say the femtosecond laser doesn't and won't have a place in microprocessing applications, merely that in these two applications pico may prove more productive than femto.

Along comes Lumera Laser, which chose Laser 2003 in Munich to introduce its new Staccato unit, with 10 W output at 1064 nm and a high beam quality (M2 <1.5) that allows the beam to be focused to less than 20µm to produce several TW/cm2 of processing power density (that's terrawatts folks), enough to ablate any material. And this unit, the company says, can be put into a factory for about $300 per day, total cost of ownership. Further, it's designed to operate for 10,000 hours under industrial conditions.

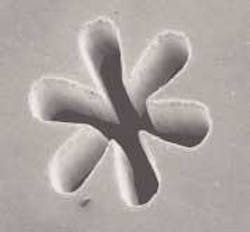

Researchers at the University of Stuttgart have produced interesting results with this unit, as seen in the accompanying photo of a 0.4mm thick spinneret, made from X5CrNi 17-7, drilled in six minutes with 10-picosecond pulses from a prototype 2-watt Staccato. The 10-watt Staccato, shown at Munich, running at reduced power, trepan drilled 25 holes of 100-µm diameter in 100-µm thick stainless steel foil in less than one minute.

At Munich, a <15-ps unit was integrated with an industrial micromachining system from 3D Micromac (Chemnitz, Germany) that offers galvo beam scanners and precision positioning and motion systems to enable up to 32 axes of part processing.

Those pursuing very short pulse microprocessing results can check out Lumera at www.lumera-laser.com and 3D Micromac at www.3d-micromac.com.