Color coding

A major change in thinking is taking place among those 'in the know' from brand owners to packaging manufacturers. The subject of this revolution is the advent of a unique non-contact and consumable-free method of applying date and lot codes (and a palette of graphics and texts) to an infinite range of packaging substrates. The color change mechanism at the heart of this new technology is the brainchild of Sherwood Technology (Widnes, England), and its Technical Centre in Nottingham. Carrying the simple but descriptive brand identity of DataLase, this is an exciting new color-change process for the high-speed printing of images using low-power laser light. This patented technology can be used for applications such as coding and dating of products, printing graphics, and security marking.

When an object is treated with DataLase chemistry it allows a laser to print images with very low power at high speed. The imaging process does not require any inks or ribbons and is virtually maintenance free, creating substantial advantages over more established methods. DataLase is fully compatible with all common printing and coating techniques.

This new laser marking technique uses only a fraction of the normal output of a CO2 laser, and thus enables high-speed marking of difficult substrates such as metals, glass, and non-laser sensitive coatings and materials. There are even foodstuff variants that can be applied direct to edible materials such as pharmaceutical tablets and confectionery products.

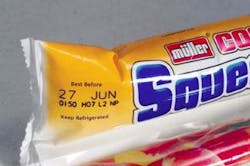

Market acceptance of this technique has been rapid with prestigious brand manufacturer Müller Dairy an early adopter for its date coding requirements.

Müller Dairy demands stringent specifications relating to the date coding and the traceability marking of its products. It sought to improve traditional methods when it recently installed new filling equipment. Most of the alternative methods are mature technologies with little or no future development potential and limited line speeds.

The Sherwood answer was to work with Alcan Packaging to print a discrete patch of new color-change ink (DataLase) in the coding/marking field at the same time as the rest of the printing. This solution was introduced quickly to several approved packaging suppliers. Müller then installed several state-of-the-art Domino CO2 scribing lasers, which were fully commissioned on the filling machines. These lasers write the required date code image onto the patch at very high speed. When exposed to the laser beam, the DataLase patch changes color from neutral to black to produce a permanent mark. As there are no solvents, inks, or consumables at the point of coding, this produces obvious speed, handling, and environmental benefits.

Hayward Green, supply chain director of Müller Dairy, comments: "We're delighted that DataLase has enabled us to improve the quality and speed of our product coding with further additional environmental benefits. The real bonus for us was the ease of implementation and the inherent advantages of reliability, high speed, and reduced downtime on our high-capacity filling lines; reflecting the versatility of this new technology." Following the successful introduction of this marking technology, Müller Dairy intends to extend its use.

As a specialist in color-change chemistry, Sherwood's core color transition technologies find application in a wide range of industrial and medical sectors. The company has a strong development heritage and it now combines technical excellence with a focused management team to provide highly innovative and creative solutions in color-change technology.

Sherwood has already developed foodstuffs and multi-colored DataLase chemistries enabling direct imaging with lasers. It is also involved in a number of strategic partnerships to expand the use of this technology into new, exciting applications, with lasers that are a fraction of the size of currently available devices.

This digital imaging process is also being evolved for industrial applications in the future such as multi-color proofing and printing, virtual labeling, and high-speed coding and marking of pharmaceutical tablets. The ultimate goal is to evolve the technology into a non-contact, full-color digital printing method.

Sherwood Technology has embarked on a major licensing and trademarking strategy for its patented DataLase technology. The company is currently in negotiation with a number of multi-national corporations who wish to license DataLase for specific territories and fields of use.

Andrew Jackson is applications marketing manager for Sherwood Technology Ltd. Contact him at [email protected].