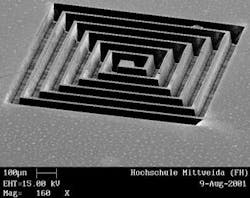

Mask projection of an excimer laser pulse can create components used in micro-system technology for medical and biotechnology applications where generation of precise structures in the order of microns or sub-microns is necessary. The laser beam irradiates a mask of the image to be produced, and a size-reduced structure is projected onto the sample, transferring a complicated pattern with a single laser pulse.

The applied technique uses masks with simple geometries, square, rectangular or circular. Complex structures are generated by precise positioning of the mask projection and synchronized triggering of the laser. In the reported tests a 193nm argon fluoride (ArF) ExciStar S-500 excimer laser from TuiLaser AG (Germering/Munich, Germany) was used. A mask with a 1mm2 square aperture was projected onto the sample surface with a 14-fold size reduction. Beam motion was achieved using a Scanlab AG (Pucheim, Germany) scanner. The beam path between the laser and the scanner is flushed with argon to prevent the formation of ozone and the corresponding loss of fluence.

Tests were performed on PMMA, a polymer that processes well at the excimer laser's wavelength and is suitable for medical applications. The ablation rate, at a laser fluence of 0.4 J/cm2, was approximately 200 nm/pulse.

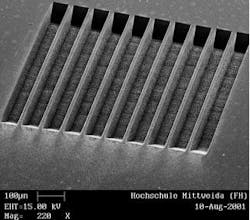

To achieve the highest surface quality at the bottom and on the walls of the structure a laser pulse overlap of 97 percent (pulse distance of 1.75 µm) was employed. Groves 70µm wide and 10-120µm deep were created. The remaining bridges between the groves have a width between 5 and 20 µm. Roughness at the structure bottom was Ra 0.5 to 0.6 µm as measured by a Dektak profilometer.

The groves slope in and out at the beginning and end of each line because of the pulse overlap. This inclination depends on the depth of the single pulse ablation and the pulse distance. Structures should be designed to accommodate the effect. The position deviation of repeated scans of the same structure was below the detection limit of 2 µm.

Highly resolved microstructures in PMMA can be reproducibly generated via mask projection using a combination of an excimer laser and a scanner. Other materials such as Pyrex also can be processed with this technique, however laser fluences of higher magnitudes may be required.

These tests were partially supported by BMBF (Innoregio InnoSachs, FKZ 03i1702). B. Keiper, J. Dunger, R. Ebert, U. Löschner and H. Exner thank 3D Micromac AG (Chemnitz, Germany) for its support. The authors are with Laser Institut Mittelsachsen e.V (at the University of Applied Sciences Mittweida, Germany). Contact Dr. Keiper at [email protected].