Source selection for laser welding

As laser welding applications expand in the marketplace, so does the choice of laser sources—fiber, pulsed Nd:YAG, diode, disk, CO2.* The decision encompasses specific aspects of the application such as material, joint geometry, weld penetration, speed, fit-up tolerances, integration requirements, and, of course, budget. Each source has a particular set of characteristics that align with weld requirements, and overlap.

Carbon Dioxide (CO2) laser—The CO2 gas laser, operating at 10604nm wavelength, with powers from 1–20kW is an extremely mature laser technology and has been a mainstay of macro laser welding since the late 1980s.

Fiber laser—This efficient diode-pumped laser is a small core silicon fiber. The lasing occurs within the fiber so there is no alignment requirement and when imaging the small core fibers in the focus head, optical focus spot sizes down to 10 microns are possible. This compact laser is provided in two configurations: single mode for low power welding (sub-300W), and so-called ‘multimode' for higher power welding.

Diode laser—The increasing power levels of single-emitter devices, new cooling channel technology, and the development of micro optics to focus the beam from arrays into sub-1000-micron core diameter fibers has given rise to the emergence of the direct diode as a welding laser.

Disk laser—A thin, flat Yb:YAG crystal disk lies at the heart of this CW laser. The disk laser design avoids the issues associated with rod type lasers by using a 0.01in-thick disk supported on one side by a heat sink. The cooling from this design enables powers in excess of 10kW with good beam quality.

Pulsed Nd:YAG laser—This pulsed laser uses a single Nd:YAG rod that is pumped using flashlamps to produce high peak and low average power for welding. For example, a relatively low power, 25W average power, can provide up to 6kW of peak power. This high peak power/short pulse width combination provides a good combination of efficient material coupling and precise energy input control.

Laser choices have been divided into penetration categories: less than 0.01in, 0.01in–0.03in, and greater than 0.03in. More than one laser source can often make the weld, but performance and budget considerations usually narrow the choice to one or two laser sources. The final selection may also be made on other factors such as pre-sale sample quality, geography, post sales support, system integrator preferences, and, of course, relationships.

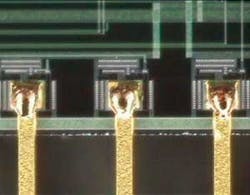

Less than 0.01in weld penetration The primary source is the pulsed Nd:YAG followed by the fiber laser. The pulsed Nd:YAG laser was specifically designed for these types of applications which require high control while accommodating part fit-up, varying weld geometries, materials, and platings. The use of high peak power enables welding with optical spot sizes up to 1000 microns providing complete flexibility in selecting the weld spot size to maximize the process window for the weld itself and necessary tolerance accommodation in a production environment.The fiber laser is the only continuous wave (CW) laser in this category because it can be focused to optical spot sizes less than 25 microns and therefore can achieve the necessary power densities required for welding. To be budget competitive in the micro segment, fiber laser power is limited to 200W, which, in turn, limits the maximum spot size to provide sufficient power density for welding to around 75 microns. This is a major limitation of the fiber laser, as trying to maintain alignment on joint/part with fit-up and stack up tolerances in a production environment with a tolerance of around ±15 microns is usually not an option.

The key application area for the fiber laser is lap welding thin materials that require fine spot sizes for stability. The fiber laser can be focused to sub-25 micron spot size with a 150mm lens, allowing sufficient working distance for tooling. The fiber laser excels in lap welding up to and beyond the 0.01in depth category at high speed; a 200W single mode fiber laser can achieve 0.004in penetration at up to 50in/s.

The pulsed Nd:YAG, by comparison, can be applied to all welding applications in this category except the thin foil welding. With such a large range of spot sizes, pulse widths, and peak power, the laser can be easily tuned and optimized to each specific welding application.

Between 0.01–0.03in weld penetration The application divide between pulsed Nd:YAG and fiber lasers described in the previous section is still valid, but to a lesser extent. The pulsed Nd:YAG handles most spot welding applications, while the fiber laser using around 500W with a spot diameter of 0.01in can be used for low tolerance butt and fillet welds. The pulsed Nd:YAG offers an interesting price vs. performance capability where both a 500W and 25W laser can offer the same weld penetration but at different speeds; peak power provides penetration capability and average power the speed of the seam weld.

With laser powers between 500–800W, the diode laser welds components with large tolerances with speeds typically slower than fiber or disk, but the tolerance accommodation may compensate for this limitation.Greater than 0.03in weld penetration All lasers are applicable to this category. The pulsed Nd:YAG laser offers penetration to about 0.05in, while the other lasers offer penetration welding to 0.25in, and some beyond 0.5in. Typically, applications for the pulsed Nd:YAG welder in this category are small, seam welded components such as pressure sensors. Beyond this, for speed and penetration, most applications are typically for the automotive, with fiber, CO2, disk, and diode technologies the options in this “macro” category.

The main differences between these sources are beam quality, brightness, and wavelength. Beam quality refers to the focusability of the laser, and brightness refers to the power density contained within the focused beam. For example, a CO2 laser and fiber laser have similar beam quality, therefore, all else being equal, would focus to the same optical spot size. Because the fiber laser is 1/10th the wavelength of the CO2 however, it can be focused to a spot size that is ten times smaller; the fiber laser has high beam quality and brightness.In laser welding, deep penetration and high speeds are directly related to high beam quality and brightness, However weld stability and tolerance accommodation tend to favor lesser beam quality and brightness. Therefore a balance needs to be found between welding performance and the quality of weld and size of the process window. It should be noted that there is always room to reduce the quality of the beam to match the application, but it is not possible to make a poor quality beam better.

The difference in wavelength between the sources has process and integration implications. The main process effect is that the CO2 laser creates a stronger welding plume above the weld, which diffuses the beam's power density, reducing penetration and enlarging the weld width at the surface. This can be alleviated by the use of an assist gas—ideally helium due to higher ionization potential, but usually argon, based on cost. The fiber, disk, and diode with their much shorter wavelengths have less of an issue with the welding plume, but still require an assist gas as the beam can be diffused by the fine metallic vapor particles created by the keyhole effect.

Regarding integration, at 10604nm, the CO2 laser must be directed from the laser to the focus head by mirrors. These can be orthogonal mirrors on a gantry type system or through articulated arms or robots to enable 6-axis motion, but the alignment through the system must be maintained as must the mirror integrity. The fiber, disk, and diode, on the other hand, can be delivered by flexible fiber optic cable thus providing plug-and-play beam delivery. The length of the fiber can be anywhere from 5m to 200m this allows the laser to be positioned anywhere around the work cell and offers the option of remote laser location if needed.

The welding speed of these lasers up to 0.25in penetration is close, with fiber and disk lasers edging out the CO2 followed by the diode. These types of welding operations using higher power lasers typically run in two shifts per day welding, which means that the selection is also strongly related to the source cost of ownership. Although the CO2 laser has a large number of users who are familiar with this technology, the price per weld of the CO2 versus the fiber, disk, and diode is significantly higher.

Laser applications exist beyond 0.25in thickness that offer real advantages over plasma and arc with significantly reduced thermal distortion. This reduction in thermal distortion maintains the part geometry such that rework of part geometry is not usually required. Part fit-up can become problematic at these thicknesses, and filler wire and/or hybrid processes that combine the laser with plasma or arc sources can be used.

Summary

There are a number of laser sources available for laser welding, and each has specific performance characteristics that align with certain application categories. It is important for the end user to have a thorough understanding of which lasers are best suited to their welding application. When a system is required, the ideal situation is to partner with a system integrator who can determine the best laser for the job.

Alternatively, for a laser only requirement, engage with the various laser manufacturers and send production-quality samples to each to find the best solution. During the selection process it is important to keep in mind that welding is a balance between penetration, speed, and weld stability and accommodation of production part fit-up and tolerances.

*CW Nd:YAG has been largely superseded by fiber and disk laser technologies and therefore is not considered in this article.

About the Author

Geoff Shannon, Ph.D.

Director Strategic Marketing for Precision Manufacturing, Coherent

Geoff Shannon, Ph.D., is Director Strategic Marketing for Precision Manufacturing at Coherent (Santa Clara, CA) and an Editorial Advisor to Industrial Laser Solutions. He previously served as Laser Technology Manager for Miyachi Unitek, specializing in the development of lasers and applications for existing and new markets. Shannon has a BEng in Mechanical Engineering and PhD in Laser Welding Technology from the University of Liverpool. His 20-year career in laser technology has centered around applications research and development and new product development of lasers and systems.