The XC60 body structure contains roughly 10 meters of laser welds in critical safety areas

by Johnny K. Larsson

In the fall of 2008 the staff in the Volvo plant in Belgium had reasons for celebration, as the first production car of the company's new Crossover Utility Vehicle (CUV), designated XC60, rolled off the assembly line. From a safety aspect the XC60 contains a large number of innovations, where the concept of “CitySafety” has perhaps received the most attention (see FIGURE 1). Through an advanced system of sensors and cameras the car can be stopped at speeds below 9 mph without any actions from the driver in the case of a car-like obstacle in front. At speeds below 18 mph the speed is substantially reduced, again without any involvement from the driver, in order to mitigate the effect of this type of low-speed collision. With the CitySafety feature, which is standard equipment on all XC60s, Volvo expects to decrease the number of accidents in dense city traffic, which is an advantage for the well being of road-users, and will also favor the level of motor vehicle insurance for XC60 owners.

Other safety features worth mentioning are Roll Stability Control (RSC), Dynamic Stability Traction Control (DSTC), Roll-Over Protection System (ROPS), Whiplash Protection System (WHIPS), Lane Departure Warning (LDW), Blind Spot Information System (BLIS), and Driver Alert Control (DAC). While none of these devices can prevent a collision, the XC60 occupant can rely on the integrated safety structure of the car body, which consists of components manufactured from the latest generation of advanced high strength steels (AHSS), presenting tensile strength in the order of 1500 MPa, and assembled by laser welding. The XC60 body structure contains roughly 10 meters of laser welds, and not just anywhere, but in areas crucial from a safety standpoint, such as A-posts, B-posts, and floor sill reinforcements.

Design considerations

Volvo management team established Sport Utility Vehicles (SUVs) attract a wide variety of customers, and it was the company's intention to find a unique niche for its next model targeting this product segment. The result—a smaller, more compact version with outspoken environmental targets in the form of materials selection, interior climate, economical on fuel, and so on, and at the same time further strengthening the Volvo safety image through a number of new features.

During early project concept and pre-study phases an increased utilization of laser technology was being discussed. This became reality thanks to a Volvo body engineering department team consisting of a new, young generation of engineers eager to try out and implement new technologies. Together with laser experts in the Gent, Belgium, plant they were tasked to create the first automotive body designed to take advantage of the unique qualities of laser processing. Earlier laser welded body applications dealt mainly with complementing or substituting for traditional spot welding, where only small adjustments of the joint geometry were made. For example the Volvo XC60 car body contains around 10 meters of laser welding divided into 17 individual welds as can be seen in the Table.

Innovative laser solutions

The design of the windscreen, or A-pillar, is a delicate task as it presents some contradictory requirements. The A-pillar should be strong and stiff to act as part of the safety cage in rollover accidents. And it should be as slim as possible to enhance the driver's visibility, which is a crucial aspect from an active safety standpoint. The solution—hot-stamped Boron steel alloyed parts with ultimate strength around 1500 MPa was selected for the A-pillar upper reinforcement (thickness 1.7 mm) and the A-pillar upper (thickness 1.1 mm). These components are laser welded together for a length of 680 mm on each side of the car body.

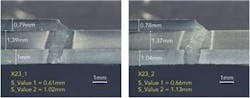

By utilizing such Ultra High Strength Steel (UHSS) material grades it is possible to reduce the cross section of the A-pillar by 30 mm compared to the larger XC90 model, which corresponds to a weight savings of 40%. The smaller section improves the driver's view around the windshield pillar. To enhance this feature, the flange to which the windscreen is bonded has been further inclined, which makes ordinary spot welding operations impossible as the welding gun can not access such a confined space (see FIGURE 2). The only possible solution was to use laser welding.

Today, every kilogram of weight saved is a benefit to both customer and society, and an example of this is the sill solution of the XC60 model (see FIGURE 3). Boron steel, 1.3 mm thick, has been used for the sill reinforcement, which enables down-gauging by 0.7 mm compared to the XC90 model, which features a 2.0mm-thick Dual Phase (DP) 600 steel sill reinforcement.

Generally the skin panel of the body side is extended to the lower flange of the sill reinforcement and spot welded to that and the inner part of the sill section through conventional spot welding. In the XC60 solution the outer skin panel is cut 5 cm higher up and meets the sill reinforcement on a flat surface. This necessitates a single-sided access for the joining operation and therefore a laser fillet welding is performed, which consists of two laser welds (531 and 220 mm long) on each side. The overall weight savings from this sill solution is approximately 8 kg out of which 1.5 kg are saved through the reduced body side.

For the B-pillar reinforcement a 1.4mm-thick Boron steel component is spot welded to an inner part that consists of 1.0mm-thick rephosphorized steel with yield strength in the range of 220 MPa. Because of severe loading conditions in side impact tests the stress concentration around some of the spot welds experienced brittle fractures in the welds and in the sheet material close to the weld circumference. To counteract this, spot welds in the mid-area of the B-pillar were replaced by 590 mm (front flange) and 500 (rear flange) continuous laser welds. These joints are actually three sheet metal stack-ups as the body skin panel is welded in the same operation. This means that the laser weld is a fillet weld between the body side, outer, and the B-pillar reinforcement, but an overlap weld between the B-pillar reinforcement and the B-pillar inner (see FIGURE 4).

Apart from the applications mentioned above also the roof is traditionally laser welded to the body sides in an extremely narrow ditch track. These welds are then covered by thin PVC sealants onto which the paint system is applied. Further the front and rear of the roof panel are welded to structural cross members, and finally we find a couple of shorter laser welds in the rear door aperture, which contribute to improved torsion rigidity (see FIGURE 5).

Lasers and welding tools

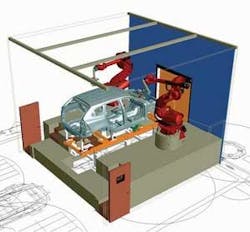

To perform this amount of laser welding two subsequent laser welding stations can be found in the GA3 body shop line of the Gent plant. The first one is the station upgraded in 2005 for laser welding of the roofs of the S60 and C30 models, which also run in this line. That station is equipped with two 4kW lamp-pumped rod Nd:YAG lasers with fiber optics and two articulated arm robots equipped with combined seam-tracking and pressure-roller tools from the Permanova Laser Systems.

The second station is new, necessary for the increased number of laser welded applications in the XC60 body (see FIGURE 6). This cell features one diode-pumped rod Nd:YAG laser and one diode-pumped disk Yr:YAG laser both of 4 kW laser output power. Also in this station, fiber-guided beam distribution to welding tools mounted on two articulated arm robots can be found. All four robots are equipped with track motion, which makes 7th axis processing possible and enables further flexibility for other laser applications in up-coming products. This layout guarantees a 100% back-up and redundancy in case of any laser disturbances and maintains the line speed in the GA3-line, which is 67 s.

Summary and future outlook

There is a distinct difference between Volvo and other automotive manufacturers concerning the introduction of more laser technology in the body shops. German competitors almost exclusively look to improved productivity and/or reduced floor space as reasons for an increased number of laser welded body applications. At Volvo laser welding is not the time limiting factor from a cycle time perspective as there are other welding operations in the assembly line that cause the bottlenecks. Also at Volvo there is already an existing industrial structure that limits floor space savings in the plants.

Therefore, the Volvo approach in finding new laser welding applications is mainly driven from an engineering perspective where we chose to utilize the unique advantages of laser technology, which enables completely new geometrical designs of the body structure. In contrast to competitors, whose “laser solutions” could just as well be possible with resistance spot weld, Volvo will restrict laser welding to areas impossible to assemble by conventional welding methods, something that will be further revealed in the company's up-coming product program.

The introduction of the XC60 represents a paradigm shift in the use of laser for body manufacturing. Next in line will be the S60 successor and a mid-size estate model, which will probably be labeled V60. Both these car bodies feature a new connection between the B-pillar reinforcement and the sill reinforcement, a concept based upon single-sided stitch laser welding. In full-scale side impact validation, these laser welds were superior to any other joining method in terms of keeping the passenger safety cage intact. The estate model, planned for launch at the Torslanda plant in early summer 2010, also features a laser brazed tailgate opening, similar to the one introduced on the Volvo V70 model in 2007.

At Volvo Car Corporation – Gothenburg, Sweden, Johnny K. Larsson ([email protected]) is the technical specialist BIW Joining Technologies.