Laser joining process yields metal-thermoplastic hybrid parts

Adhesive bonding and laser remote technology join plastic to metal

ANNETT KLOTZBACH

Load-adapted hybrid connections made of metals and thermoplastics have become more important as they are used for several industrial applications, especially in the area of lightweight construction. For efficient process chains and specific load cases, an optimized pretreatment and joining technology, as well as adapted tools for process simulation and characterization of properties, are required. For this purpose, the laser can be the key to success.

With a strict implementation of function-integrated lightweight construction, local load differences influence the use of materials of different classes. The connection of the various subcomponents places special demands on the joining technology. For example, metal inserts and screw bushings are bonded onto plastics during the injection molding process. Preferred joining processes are the attachment of clips, screw connections, or rivets. However, gluing has also increasingly found its way into the automotive industry, especially where plastic fairing parts are bonded with metallic stiffening structures.

Consider the tailgate of a BMW i3, for example, where more than 11 meters of adhesive seam provide structural strength, improved crash performance, and simple tolerance compensation.

An industrial bonding process also has its difficulties, though. While in mechanical connections, the transfer of loads is achieved by means of a pure form and force fit, but bonding requires an optimized material contact between the surfaces. The adhesive forces acting on the boundary layer of both materials, which is only a few microns thick, react very sensitively to changes. Contamination by oils and preservatives or flatness tolerances can lead to drastic losses in strength. To achieve transmission strength comparable to that of a screw connection, large surfaces are bonded.

However, bonding proves to be uneconomical due to the process sensitivity, the required connection area, and a large number of individual process steps. Typically, both joining partners are cleaned or pretreated before bonding, followed by the application of the adhesive, fixation of both joining partners, and the curing of the adhesive (chemical reaction).

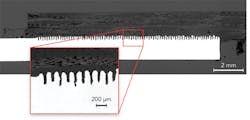

Efficiency increases of the industrial bonding processes have, for example, been achieved by using a laser pretreatment. Here, the surfaces are cleaned from contaminations and simultaneously roughened, mostly by pulsed lasers to increase the area reacting with the adhesive. If this ablation process is intensified—for example, by using continuous-wave (CW) power lasers in the kilowatt range, deep trench structures can be created (FIGURE 1). Filling the resulting cavities with adhesives or plastic melt, a macroscopic form closure is created.

FIGURE 1. Laser surface pretreatment of mild steel before thermal direct joining is shown.

This pretreatment strategy now offers the possibility of joining materials more reliably by means of combination of adhesive bond and form fit.

Fast joining due to controlled heating

Another approach to simplify the production of hybrid connections is thermal direct joining, in which metal and thermoplastic are pressed together. Rapid heating of the metal causes melting of the thermoplastic in the contact area, which wets the surface and solidifies during cooling. This principle can be applied to surfaces of any size and to various material combinations. Due to the clearly different coefficients of thermal expansion, high shear stresses occur in the boundary layer. To be able to absorb these stresses in addition to the loads occurring during the use, either the plastic must be modified or the metallic surface must be pretreated.

An industrially preferred process is the coating of the sheets with adhesion promoter systems in the coil coating process. The metallic semi-finished products are coated, formed, and punched. Subsequently, thermoplastic fiber composite parts can be bonded onto the metal by hot pressing.

Here, it can also be shown that brilliant-power lasers simplify pretreatment. The macrostructures produced on the metal surface are filled with the molten thermoplastic during thermal direct joining. During solidification, the thermoplastic shrinks and thus hooks into the metal structure.

Laser ablation ensure optimum plastic anchoring

Currently, various approaches to topography design for optimized thermoplastic bonding are being investigated. For example, ultrashort-pulse lasers generate specially shaped microstructures that can be penetrated by the low-viscosity plastic melt. In contrast, the approach by researchers at the Fraunhofer Institute for Material and Beam Technology(Fraunhofer IWS; Dresden, Germany) is based on the use of CW lasers to produce coarse structures with ablation depths up to 200 µm, so that fibers and highly viscous plastic melt can also penetrate and anchor themselves.

FIGURE 2 shows the cross-section of a thermal direct joined connection. The structures were completely filled with matrix and fibers. Depending on the type of load, different ablation regimes are used. Simple line and cross structures offer a good possibility to fill the cavities completely with plastic. The combination of ablation and the melting process provides an additional undercut due to melt adhesion. Using a solid-state laser with high beam quality (for example, 3 kW laser power), ablation rates of 100 to 500 mm2/s (typical) are achievable.

FIGURE 2. A cross-section of a metal-thermoplastic connection (mild steel and glass fiber-reinforced PA6), which was accomplished by thermal direct joining and laser macrostructuring, is shown.

Laser structuring is not everything

Thermal direct joining only proves to be efficient if the metal is heated and cooled very quickly. This can be done flexibly by short-term heating using laser radiation. Similar to a surface-hardening process, the metal is heated from the side facing away from the joint. The rapid heating of any surfaces is possible by the combination of a fast, controllable power laser in the 800–1100 nm range and a scanner optic. FIGURE 3 shows the stiffening structure of a middle armrest made of fiber-reinforced PA6 and mild steel. Here, the welding assembly and the cover plates were connected to an organo sheet by means of laser heating.

FIGURE 3. A stiffening structure of a middle armrest (feasibility study) made from joined mild steel and glass fiber-reinforced PA6 is shown.

Since the joining interface is not directly accessible, the sheet thickness and the temperature gradient generated in the metal are specific because the melting temperature of the thermoplastic must be maintained. The contact pressure also plays an important role, as it balances the tolerances so that the cavities can be filled by plastic and fibers.

However, there are also disadvantages with the laser process. The principle of thermal direct joining is based on simultaneous pressing of the parts against each other and heating. Therefore, a direct accessibility to all joints must be guaranteed. With complex parts, this is often impossible.

Fast heating by induction

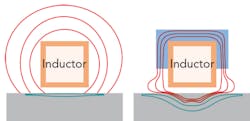

In the case of complex accessibility, short-term heating by induction offers many advantages. An electromagnetic alternating field is created by a geometry-adapted current-carrying coil, which generates eddy currents and thus heats the electrically conductive joining partner. Depending on the frequency range used, either volume heating takes place or the heat is generated directly in the boundary layer by exploiting the skin effect.

In contrast to laser heating, which can easily be adapted to different heat dissipation conditions by scanner systems, inductive heating requires a geometry-adapted coil design. Corresponding finite element simulation tools have therefore been developed and validated at Fraunhofer IWS. They are based on the COMSOL Multiphysics platform, and consider the local energy coupling as well as the material-dependent heat conduction. Since in most cases it is only possible to work in the outer field of the coil, it is also necessary to use field concentrators. With a suitable design, the coupling efficiency can be increased up to a factor of 10. FIGURE 4 shows the basic principle of eddy current guidance using field concentrators.

FIGURE 4. The basic principle of eddy current guidance using field concentrators for heat efficiency increase.

Induction or laser heating: which is the best?

Comparative studies with both laser and inductive heating have produced comparable joint strengths. To compare the results obtained with bonding, tensile shear tests were carried out on single overlapped joints in accordance with DIN EN 1465 (joining surface: 12.5 × 25 mm2). The strength of material combinations of continuous glass fiber-reinforced PA6 with stainless steel, aluminum, or mild steel was approximately 25 MPa. The fracture occurred almost exclusively in the base material of the composite. When using higher strength materials such as carbon fiber-reinforced polyetherketoneketone (PEKK), strengths of up to 30 MPa with partial fiber breakage could be achieved. The strengths determined are in the range of systems joined or bonded with adhesion promoters. The resistance of the joint to alternating climatic loads was also successfully validated.

If, on the other hand, the load limits in oblique or head tension are considered, it must be stated that there is still a need for research. This results from the adhesion mechanism, consisting primarily of a form-fit with small amounts of adhesion bond.

When considering the achievable joining times, significant differences between inductive and laser heating could be determined. Therefore, induction enables more targeted heating so that, for example, the above-mentioned standardized joining surfaces of mild steel with 1–2 s heating time was required. In the case of laser heating, 3–5 s had to be applied to heat the mild steel through without locally risking melting of the surface.

Thermal direct joining has been developed and qualified by research institutions and companies for several years. However, the industrial applications in series production are still very limited. The reason for this is the complex component design leading to function-integrated hybrid designs. The choice of the right material in the right place requires the innovative viewpoint of the designers. The pure substitution of a metal component by a plastic or composite part leads to weight savings on the one hand, but at a significantly higher cost. Nevertheless, certain areas of application for the technology have already crystallized. For example, laser structuring before injection molding is used as an alternative to primer application or plastic modification for small series production. In thermal direct joining, the industry aims to manufacture housing components or connecting elements from temperature- and media-stable thermoplastics to connect them to die-cast aluminum. Additional flanges for a screw connection, as well as seals, can thus be omitted.

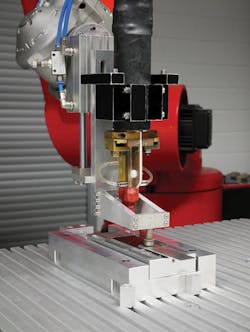

FIGURE 5. A robot-guided spot-welding gun for metal-thermoplastic connections is shown.

In addition, the technology has been further developed so that automated point-like joining is also possible. With the technology marketed as HeatPressCool-Integrative (HPCI), the joining partners are pressed together similar to a conventional spot-welding gun (FIGURE 5). A ring inductor arranged around the punch heats the joining area. The thermoplastic melts and binds to the metal. The special feature of this technology is the possibility of locally connecting plastic panels to metal inserts for use in, for example, kitchen utensils, lamps, and other consumer products.

FIGURE 6. Fixation of composite structures for local stiffening using HPCI technology is shown (also see http://s.fhg.de/hpci-clip).

Furthermore, larger components can be flexibly pre-fixed to overall structures or directly bonded. Due to the compact design of the system technology, the tools are designed in such a way that conventional handling technology can be used (such as industrial robots), and thus the HPCI technology can be integrated into complex assembly chains (FIGURE 6). This is the best precondition for a comprehensive introduction to industrial manufacturing. ✺

ACKNOWLEDGEMENT

HPCI is a registered trademark of Fraunhofer IWS.

ANNETT KLOTZBACH([email protected]) is Group Leader, Bonding and Composite Technology at the Fraunhofer Institute for Material and Beam Technology (Fraunhofer IWS), Dresden, Germany; www.iws.fraunhofer.de.