A telescopic refractive optical system transforms a Gaussian beam to a flat top beam

Alexander Laskin

Is your laser beam truly effective? If not, how can you change the beam intensity profile to optimize a technological process? These questions are of great importance for various industrial laser technologies, especially for applications such as laser marking and engraving. Often the performance of a particular technology could be improved essentially by homogenization of a laser beam. This is one of the reasons for recent growing interest in various beam shaping techniques.

The non-uniform nature of laser radiation can be a source of difficulty in applying lasers-for example, effects such as heat-affected zone (HAZ) in welding or cone-shaped holes in laser drilling-and it is also a concern for the loss of costly energy.

This statement can be illustrated by a geometrical consideration for a single-mode (or TEM00) laser beam, the type of laser beam often used in various materials processing technologies because it provides the largest energy concentration. Of course, each laser application has its own features of material and laser radiation interaction. There is, however, something common for all single-mode lasers-the Gaussian function of intensity distribution. Therefore, to evaluate the laser beam’s efficiency it is possible, as a first approach, to consider just the geometrical features of the Gauss function, without taking into account effects accompanying laser treatment of materials like burning and so on.

Figure 1 shows the Gauss intensity distribution in a section of laser beam, where Ih is a working level of intensity when an effect from material treatment of a certain kind happens. “The energy figure” of the laser beam has three parts:

• E1- an apex of Gauss is an excess of energy over the working level Ih, • E2- “tails” of Gauss that almost always are losses of energy, and • E3- “effective cylinder” of energy.

Results of calculations for “parts of energy” are presented in the form of diagrams at the right in Figure 1 (a complete description is presented in reference 1).

FIGURE 1. Evaluation of efficiency of using the laser beam

These results are very interesting. The unconditional energy loss E2, tails, can reach a very high level. For example, if a working energy level is half of maximum (often just this level is considered as a working one) the energy losses are 50 percent of full laser beam energy. In the case of laser treatment of thin films the energy part E1, apex of Gauss, is also considered as a loss of energy because this part exceeds the working energy level Ih. Thus both energy parts E1 and E2 are losses. Their sum E1 + E2 is shown in the diagram as well; minimum of this function is 0.63. In other words, when treating thin films, in the best case, “only” 63 percent of energy is lost and 37 percent is effective.

This is geometrical interpretation only. However, this approach makes it possible to get an idea of how much laser radiation is lost; losses can sometimes reach a half of total laser energy.

No doubt, transformation of the original Gaussian shape to an effective cylinder, called a flat top or top hat profile, would help to save laser energy and improve those technologies where uniform intensity is most desirable. There are several types of optical systems suggested to accomplish this transformation: refractive, diffractive, beam integrators, or combined systems. The choice of a suitable solution depends on power level, wavelength, quality of beam homogenizing, and other features of a particular task.

This transformation is a main function of the πShaper, a family of refractive beam shaping systems intended to work with UV, visible, and IR lasers.

The concept of πShaper’soperation is illustrated in Figure 2. The Gaussian intensity distribution of a collimated TEM00 laser beam is converted to a flat top distribution (similar to a Greek letter π). The output beam is also collimated and is nearly the same size as the input beam.

FIGURE 2. πShaper converts Gaussian beam to flat top.

The technology of energy conversion makes it possible to create almost arbitrary intensity distribution of output beams. However, most often just a flat top distribution is required. From this point of view, πShaper is a telescope, related to so-called refractive field mapping systems,2,3 where intensity profile is transformed in a controlled manner and one of the basic principles is zero wave aberration of the entire system. These features distinguish the πShaper from integration type homogenizers where uniform intensity is provided by applying multi-lens optical components and mixing parts of the original beam (beamlets) in a certain working plane. In contrast to beam integrators, the flat top intensity profile created by this devicestays invariable over a long distance. This feature simplifies its application in real systems.

The Galilean telescope type of πShaper guarantees the beam shape transformation without internal focusing, which is important for high-power and short-pulse applications. At the same time, it has an achromatic design that makes it possible to use the same unit with various laser sources. When optimized anti-reflection coatings are applied to this refractive type optical system it is possible to reach nearly 100 percent transmission of laser radiation; a great advantage over the diffraction type homogenizers.

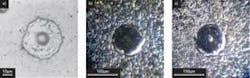

FIGURE 3. Holes made in Si, DPSS Nd:YAG laser, TEM00 , ~18 J/cm2, 10 pulses:

Because of their features, these beam shaping systems find application as useful instruments to improve industrial laser technologies and in solving some scientific tasks. An example of a successful application is in laser micro-drilling of silicon by Ekspla Ltd. (see Figure 3). Here a hole is made in silicon by an Ekspla DPSS Nd:YAG nanosecond laser without (a) and with (b, c) using the πShaper. The task was to reach a “flat bottom” profile of blind holes without any HAZ at the edges. This process is important in manufacturing multilayer PCBs.

The difference in the results is evident. When using the Gaussian beam to drill a hole, its shape is tapered (Fig. 3a)-too much energy in the center and not enough at the periphery of a hole. High intensity in the center of a Gaussian beam could exceed the ablation threshold of the copper layer underneath.

The hole shape changes drastically when the πShaper is used. The shaped beam passes through a circular aperture and the aperture plane is projected, with 50X demagnification, to the surface of a silicon wafer. The holes created with a flat top shaped beam exhibit well-defined rims and a flat bottom (Fig. 3b, c). The “flat bottom” shape of the holes is stable over a wide range of shifts from the image (focal) plane. One can compare the results achieved in focal plane, (b), and in the plane shifted for about 100 μm (c). Finally, applying πShaper helped to solve the task of drilling the holes of required shape with the depth of field necessary for industrial drilling machines.

Beam shaping opens new possibilities for improving the performance of those laser technologies where a uniform intensity profile is most desirable. With further developments, beam shaping systems may be applied in solving industrial and scientific tasks more easily and simply.

Acknowledgments

The author is thankful to Gediminas Raciukaitis, Ekspla Ltd., for his help in preparing this article.

Alexander Laskin ([email protected]) is project manager, MolTech GmbH (Berlin, Germany; www.MT-Berlin.com).

References

1. A. V. Laskin, “How effective is using of laser beam?” www.mt-berlin.com.

2. F. M. Dickey, “Laser Beam Shaping,” Optics and Photonics News, 30-35 (April, 2003).

3. J. A. Hoffnagle, C. M. Jefferson, “Design and performance of a refractive optical system that converts a Gaussian to a flattop beam,” Appl. Opt., vol. 39, 5488-5499 (2000).

(a) Gaussian beam (b) withπShaper 6_6, focal plane (c) withπShaper 6_6, ~100 µm shift from focus.

Ekspla Ltd.