Laser process extends the service life of single-crystalline turbine blades

Mark Hendriks

Sulzer Elbar, a Sulzer Turbo Services company, has developed a repair procedure for single-crystal (SX) hot section gas turbine blades. The repair does not affect the original integrity of the base material structure, which is a prerequisite for further operational performance of the blades. As microstructure, mechanical properties, and dimensions are restored to an “as-new” condition, blades repaired by Sulzer Elbar can be put back into service for at least another operating interval. This repair capability finally enables users of SX blades to achieve significant cost savings, as normally these high-cost blades are declared scrap after only one cycle of operation.

The search for increased power output using higher turbine inlet temperatures over 1300 °C has led to the application of SX materials for turbine blades. In recent years, in most modern industrial gas turbines that operate at high inlet temperatures, SX alloys have replaced the conventional, creep-resistant, polycrystalline cast nickel-base superalloys used as material for hot section gas turbine components.

Superior material

SX alloys have superior properties, but they do not contain grain-boundary-strengthening elements. Therefore, the formation of stray grains and recrystallization must be avoided at all costs, because the grain boundaries resulting from recrystallization in SX alloys are extremely weak and thus act as initiation points for failure.

Normally, an advanced cooling system reduces the metal temperatures on the SX components during service (see Figure 1). The result of the advanced cooling is a homogenous temperature distribution on the airfoil, which makes the component less sensitive to thermal fatigue damage.

FIGURE 1. Single-crystal (SX) blades are common in high-performance gas turbines. This X-ray photograph shows the cooling passages in a first-stage blade. A new procedure by Sulzer Elbar extends the service life of these valuable components.

null

Component degeneration

Despite the use of high-end materials, various damage mechanisms still occur during service (see Figure 2). Typically, low-cycle fatigue affects the coating in the fillet area at the concave side of the platform, resulting in crack formation. In addition, spalling of coating is observed. Corrosion attacks the platform of the blades and the tip pocket towards the trailing edge.

The microstructure degenerates because of high service temperatures. The γ’ particles-precipitates in the microstructure of the base material that are, among other factors, responsible for the strength of the material-coarsen and detrimental needle-shaped phases form. These mechanisms deteriorate the mechanical properties and shorten the remaining lifetime of the component.

Repair is possible

In general, repair processes influence the microstructure and macrostructure-and thus the mechanical properties-of the base material. During the repair of SX components, it is of critical importance that the repair procedures do not influence the macrostructure of the base material in order to avoid deterioration of the mechanical properties. It is not required, however, to extend the SX structure of the base material into the repaired sections. Within the chemical composition of the filler metals used for the repair, grain-boundary-strengthening elements are present. Therefore, under specific conditions, grain boundaries can be allowed, but only in the repaired sections of the component. The mechanical properties of the filler metal must comply with the mechanical properties required in a localized area of the component. In addition, changes to the advanced cooling system of the blades must be avoided during repair to ensure the cooling integrity of the component.

Procedure developed

Until recently, no established repair procedures for the refurbishment of SX blades existed. With newly developed processes, Sulzer Elbar is now able to repair the typical damage on SX first-stage blades. Extensive research has proven that the proprietary repair procedure does not influence the base material, which is essential to retain the material strength.

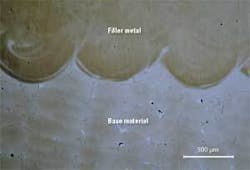

FIGURE 3. The microstructure at the interface between the SX base material and the weld filler metal, applied by laser powder welding.

Laser powder welding is used to restore the burnt tip pocket without affecting the microstructure and macrostructure of the base material (see Figure 3). The corroded platform of the blade is restored by a powder repair technology with the selected additive material chosen specifically for its excellent resistance against hot corrosion. Following repair, Sulzer Elbar applies advanced coatings as a final touch using Sulzer Metco’s advanced coatings.

null

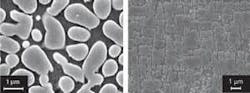

FIGURE 4. The influence of the rejuvenation heat treatment on the microstructure of the base material: The photographs on the left side show the needle-shaped particles and the coarsened γ’ distribution before the heat treatment. On the right, the original microstructure has been restored.

Post-repair destructive examination showed that the degenerated microstructure was fully restored (see Figure 4). The detrimental needle-shaped particles had been dissolved by a solution heat treatment, and a rejuvenation heat treatment had restored the original γ’ distribution. The resulting mechanical properties fully match those of virgin material.

Substantial savings

Without a suitable repair procedure, SX blades must be replaced at every major overhaul after approximately 24,000 operating hours. Until now, users had to allocate huge financial resources for the replacement of single crystal blades-the value of an SX blade is close to its weight in gold.

Damages and defects that are considered relatively harmless for conventionally cast and directionally solidified blades pose a considerable risk to SX blades. Therefore, thorough inspection is the key to lifetime extension of single crystalline blades. In conjunction with regular inspections, Sulzer Elbar’s repair capability enables the users of SX blades to do the following:

• obtain maximum use of their high-cost blades

• operate reliably with repaired components at a fraction of the cost of new blades

• operate the blades after refurbishment for at least another cycle of 24,000 to 32,000 operating hours before overhaul

Based on the investigations and the advanced repair techniques developed by Sulzer Elbar, SX blades can now be refurbished to an “as-new” condition. With the high-end repair technology and the know-how of Sulzer Elbar, users of SX blades can give a second life to these components and thereby achieve substantial savings.

Mark Hendriks, Sulzer Elbar B.V., The Netherlands, can be contacted at [email protected]. Article © Sulzer Technical Review, Sulzer Management Ltd., Winterthur, Switzerland.