The combination of low-cost CO2 lasers and global commerce has spawned a fast-growing “cottage” denim industry in China

David Clark and Angelo Petrogalli

Lasers, particularly carbon dioxide lasers, have a long and successful, albeit low-profile, history in the clothing and fashion industry. Notable examples include marking buttons, cutting garment labels, patterning designer neckties, and cutting shoe leather. Reasons for the use of lasers in the apparel industry range from lowering cost to process flexibility and even anti-counterfeiting. For example high-end necktie manufacturers often store their artwork digitally rather than as physical patterns in order to minimize theft risk. These digital patterns are then turned into physical print tools when needed using lasers.

Now the new and fast-growing application of denim engraving has emerged where the use of lasers replaces earlier denim-distressing technologies and is taking the value-added results to a level of sophistication unattainable by non-laser methods. The main center for this industry is in China. The unique structure of this off-shore industry requires laser tooling that combines performance with low cost, specifically, by eliminating the high-end handling systems often found on laser workstations.

Distressing and engraving

During the California gold rush, Levi Strauss made the decision to use some heavy-duty blue cloth to make a pair of simple hard-wearing trousers rather than a tent. This turned out to be a momentous decision that ultimately spawned a billion-dollar denim industry. (The word denim comes from an early name for this fabric-Serge de Nimes-based on its birthplace in Nimes, France.) In fact, the value of all the jeans ever made would now far outstrip the value of all the gold that ever came out of California. In addition to the sheer size of the blue jeans market, today Strauss would probably be just as amazed to see what has become of his humble pair of trousers. Over the years these have transitioned from rugged “blue collar” work clothes to hippy attire to today’s high-fashion “shabby chic” statement. Perhaps more surprisingly to Strauss, who chose the indigo die cloth for its tough durability, current fashion prizes jeans that appear torn, worn, bleached, or distressed in some way. With the possible dubious exception of fake antiques, jeans (and some related apparel) are the only manufactured products where value is added by actually making these look old and used. A few of the many cosmetic techniques and styles used for this purpose include acid washing and sand blasting to create faded spots and areas, whisker washing to produce characteristic white whiskers below the front pockets, and “slub” weaving to give a crudely woven appearance. But none of these offer the sophisticated and dramatic possibilities of laser engraving.

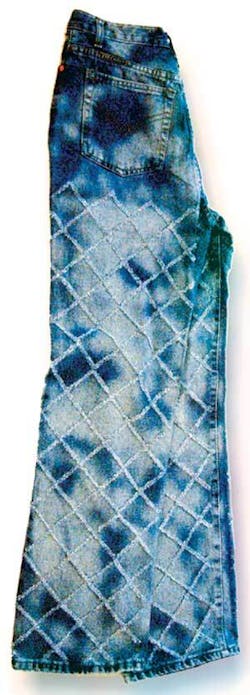

FIGURE 1. Laser engraving can be used to create a wide range of patterns in raw denim or finished jeans.

The principle of laser engraving is very simple. A focused laser beam is used as a precision tool to photo bleach the denim on demand, creating everything from complex fractal patterns (see Figure 1) to personalized signatures and even monotone photographic images. Photo bleaching is a well-established whitening technique used for clothes and even skin and teeth, but it generally uses ultraviolet light to directly break chemical bonds and thereby bleach the colored organic compounds involved. However, even though fashion denims can easily command $200/pair and higher, the economics of this application preclude widespread use of ultraviolet lasers; these photons are simply too expensive for the fashion industry.

Sealed CO2 lasers

The lowest-cost photons from industrial lasers are obtained from the sealed carbon dioxide laser, which is the tool of choice in this application. But this laser supplies infrared output that normally processes material by intense local heating, creating a corresponding heat affected zone (HAZ) of peripheral thermal damage. In recent years however, pulsed laser resonators have been developed with very fast rise and fall times. This enabled cutting of plastics, paper, textiles, and other “delicate” organics without causing cosmetically unacceptable HAZ effects such as charring.

Denaturing dyes without damaging the fabric is even more difficult than processing organics. In some applications, the laser is used as the only process step, in other applications the laser removes the blue color and the effect is then “fixed” with a chemical process. Also, lasers are used both to mark raw denim as well as to “personalize” finished jeans. In all cases, there is a very narrow process window that requires extreme laser stability, complete control of pulse duration and energy, dynamic auto-focus, and power on demand.

The key is to deliver the optimum power density for fast surface bleaching, without weakening the underlying fabric. Laser power, pulse characteristics, focus spot size, and dwell time are all interrelated and must be tightly controlled. The typical denim engraving machine combines linear motion of the material with XY galvanometer scanning of the focused laser beam and real-time Z axis focusing. For a 100-watt RF pulsed laser, the typical optimum dwell time in the middle of a galvanometer sweep is around 200-300 microseconds. But with galvanometer vector scanning, the motion of the laser spot is much slower at the corners of a scan. And the detailed patterns produced in denim translate into a lot of scan corners-and corners with different angles at that.

The self-contained laser engraving machines from DS4 (Pedrengo, Italy) utilize the GEM and K series CO2 lasers from Coherent (Santa Clara, CA) to solve this problem because they offer “power on demand,” with control down to the single-pulse level. In these machines (see Figure 2), the laser pulsing rate is automatically varied in real time by the machine’s computer, synchronized to the vector scanning. So at tight corners, the delivered power is smoothly decreased until it actually reaches zero as the scan motion is reversed.

FIGURE 2. Denim engraving systems are available with a variety of laser powers and materials handling capabilities. The Freestyle system from DS4 incorporates a vacuum table and a sealed CO2 laser (Coherent Diamond series) with powers up to several hundred watts.

This is made possible by the use of a high-speed software package running directly in RAM on the Linux operating system. Up to 1000 individual commands may be executed during each cycle of this software, which runs at a 40ns refresh rate with a temporal resolution of 4ns. High-speed automated functions include dynamic Z-axis auto-focusing, which is particularly important when dealing with denim fabric that is much less flat than say a metal or plastic substrate.

With these systems, DS4 has developed several unique effects for jeans manufacturers utilizing the 65,000 gray scale that the engraving software delivers. This includes fake embossing as well as fake mends. Moreover, multiple effects can be created simultaneously, such as acid washing and embossing (see Figure 3). And by reducing the scan speed and/or increasing the pulse repetition rate, the system can automatically incorporate cut holes in addition to these sophisticated bleaching effects (see cover photo).

FIGURE 3. The laser tool can be used to create two effects simultaneously, as in this pair of custom denims, which have an acid wash and checkered “embossed” look.

null

Low-cost solutions for China

Like many other segments of the apparel industry, most of the denim engraving applications are performed in China where the work is done by small subcontractors, each often operating just a single laser system. This strongly impacts the type of machines that the market will support. For example, laser engraving can be successfully performed with lasers rated anywhere from 40 watts to 600 watts. Throughput increases with laser power, but so does system cost. Because cost is such a big factor to small manufacturers, most of the market is at the 100-watt power level, particularly for uncut denim rolls. These roll-to-roll machines have to be as simple as possible in terms of material handling to minimize system cost while maximizing reliability. For example, the preferred material handling system consists simply of a steady motion, single-axis, roll-to-roll feed. Laser reliability is also critical for end users who cannot afford to inventory spare laser heads.

What about return on cost? At the 100-watt power level, typical patterns can be created at a feed rate of one square meter per minute. The unprocessed denim has a bulk value of approximately $1 (U.S.) per square meter whereas the engraved denim has a typical value around $15 per square meter. Excluding the cost of consumables (mostly electricity), this translates into a gross profit of $14 per minute, or $840 per hour.

The lower-power systems that are based on 40-, 70-, and 90-watt lasers are predominantly used to create small patterns and signature type motifs on finished denim. This is a business that has really benefited from the internet and global commerce. Customers specify the size of jeans that they need and supply the manufacturer with a digitized file of a photo, signature, or other pattern. The finished jeans are then laser engraved and drop-shipped to the customer. Alternatively, systems at the 70- to 90- and 150- to 200-watt level are often used to create a pattern over the entire pair of jeans. Examples include crocodile skin and elephant skin effects. Typical processing time for this is around one minute per pair of jeans.

There is also a market for 300- and 600-watt laser systems. Because of their higher cost, these are usually operated on wholesale bulk denim. To date, there has been very little demand for systems at power levels above this point due to the cost of these lasers and because, at this power level, there is the potential for damaging or burning the fabric.

Conclusion

Traditional applications for CO2 lasers primarily involved simply heating or melting a material. However, the development of increasingly sophisticated CO2 lasers offering enhanced pulse characteristics and highly controllable output has enabled them to accomplish more demanding materials processing tasks. These expanded capabilities, together with the high output power and low total cost of ownership for CO2 lasers, continue to broaden their application space.

David Clark ([email protected]) is with Coherent Inc., and Angelo Petrogalli is with DS4 Laser Technology (Pedrengo, Italy).