The art of laser marking

Achieving the balance between speed and performance

Pat Grace

In laser marking, as with many other industrial processes, there is almost always a tradeoff between mark quality and mark speed. Better character formation, higher contrast, or greater mark depth require more precision and lower beam travel speeds at the workpiece. Small beam spot sizes allow the user to create smaller characters and finer mark details, but if the spot is too small, linewidth and mark contrast will suffer. Different laser types produce different beam wavelengths. The wavelength will affect how the beam reacts with different materials; one wavelength may create high contrast at very high speeds, while another wavelength may mark very slowly, or not at all. All of these factors, along with customer budgets, need to be considered by the manufacturers creating today’s high-performance laser marking systems.

null

Key process parameters

The majority of bare metal laser marking applications today are done with Q-switched Nd:YAG lasers. This laser type provides a short pulse (from 10 to 100 ns) with high peak power. These characteristics allow the focused spot to vaporize the metal, which is necessary for the laser to engrave into the material. Another factor impacting the engraving process is focused spot size. Reducing the spot diameter by 50 percent multiplies the power density by a factor of four. Modern diode-pumped Nd:YAG lasers have spot sizes around 0.002 inch while typical lamp-pumped Nd:YAG lasers have 0.005-inch focused spots.

Ferrous metals as well as titanium also can be marked with a technique referred to as annealing. With this process, the metal is heated up to a point below its melting point, which allows a thin metal oxide layer to form. The color of the layer is dependent upon the surface temperature generated by the laser beam on the material. While engraving requires very high peak power density to vaporize metal, annealing uses longer pulse durations and larger focused spots to yield much lower power density.

Marking of synthetic materials and paint layers borrows some techniques from metal engraving and annealing. This style of marking is done with medium length pulses to minimize heat affect without coupling excessive energy into the material, which would cause bubbling, blistering, or melting. As much less energy is required to create a color change on synthetic material, higher pulse repetition frequencies can be used and very high surface velocities. The end result is much faster marking on synthetics than on metals, with a cycle time for an equivalent mark taking less than one tenth the time it would take to mark on metal.

Laser design factors

The challenge for the manufacturer is to optimize this wide range of parameters, all of which are interdependent in varying degrees. As an example, pulse energy and peak power decrease as pulse frequency increases. If high peak power is needed, the pulse frequency can be lowered, but then the scan speed must be decreased or mark spots on the material may separate enough to become individual dots. To avoid this contrast reduction, the laser must be designed to minimize pulse duration, even at high pulse frequencies. Shortening the pulses compresses the available pulse energy into a smaller slice of time, causing the peak power to increase.

Shorter pulse durations require short laser resonators and Q-switched pulses. By design, lamp-pumped lasers have long resonators because their high heat input creates substantial thermal issues, degrading the beam quality. The long resonator is then the only method available to recover some of the lost beam quality. Long resonators are also necessary in fiber lasers because introduction of the pump light into the fiber requires significant length to get complete absorption. Fiber lasers can recover some of the peak power lost to the long pulse with their inherently high beam quality and small focused spots. The small diameter of the fiber (typically less than 0.1 mm) used in fiber lasers yields a high quality beam, but not without a sacrifice. Pulse energies must be kept below a threshold, otherwise internal damage to the fiber will occur. For most fiber lasers, this damage threshold occurs if the laser is pulsed below 20 kHz.

Diode-pumped Nd:YAG and Nd:YVO4 lasers offer an excellent general-purpose compromise to the design tradeoffs mentioned above. Because the pump diodes emit light only at the needed wavelength, heat input and thermal effects are kept to a minimum. This allows the use of much shorter resonators without sacrificing beam quality and spot size. The beam diameter within the resonator is also large enough to allow very high pulse energies and pulse peak powers without causing any damage to the laser itself.

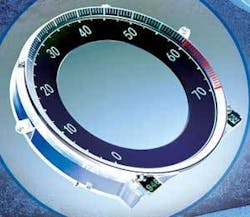

Greater material sensitivity requires better consistency of the pulse energy emitted by the laser. Diode-pumped laser designs are very good from this standpoint. Minimal heat input means minimal changes in beam quality throughout the operating range. Care must be taken to control the first pulses emitted during the mark process. First pulses occur every time a new character stroke is initiated. Because the laser is not pulsing between strokes, extra pump energy is built up in the laser rod. When the laser begins pulsing again on the next stroke, this can lead to a bright spot or first pulse dot on the mark surface. This is particularly noticeable when marking on the mold compounds used in the semiconductor industry and also when marking on day/night buttons and switches. On semiconductor materials, a large first pulse will dig into the material, possibly damaging the delicate circuitry inside. When marking day/night products, first pulses will cause bright spots obvious to the end customer. The latest marking system designs utilize modern electronics to control not just the first pulse, but all of the pulses generated until the laser reaches a steady state marking condition.

Conclusion

There is not one single tool that meets all possible applications. Different laser types provide different parameters, wavelengths, pulse energies and focused spot sizes. Diode-pumped Nd:YAG lasers are the superior choice for demanding applications such as engraving and high-quality annealing. If price is the primary purchase criterion, fiber lasers offer an acceptable solution, although with limitations on engraving depth and linewidth. Even though CO2 lasers have large spot sizes and limited peak power, they provide good applicability on wood and paper items along with a small percentage of synthetic materials. Regardless of the laser type chosen, application expertise and software also make a significant contribution to mark quality and ease of operation. Before any purchase decision is made, the end user should receive sample marks on their own material and they should also witness a thorough demonstration of the operating environment. Even the least expensive laser marker on the market is a substantial investment and the customer needs to know what they are buying.

Pat Grace is a regional sales manager for TRUMPF Inc. on the West Coast. For more information, visit www.us.trumpf.com.