As an alternative to traditional mechanical drilling processes for natural stone, multi-shot percussion drilling is faster, more flexible, and requires no chilling liquid

J. Pou, F. Lusquiños, A. Riveiro, R. Soto, M. Boutinguiza, and F. Quintero

From the onset of civilization, stones have played a significant role in all human activities. The demand for stones for both construction and decorative purposes never ceased and became more and more important. This fact can be easily demonstrated from the constant increase observed in the stone production through the years. Twenty years ago the total production of ornamental stone was 21.7 million tons, whereas this figure increased to 88 million tons in 2004-an increase of more than 400 percent in 18 years. This translates to a sustained yearly increase average of more than 20 percent during the last two decades.

The stone industry is of strategic importance to some economies. A significant percentage (65 percent) of the total world production can be attributed to the European countries, representing a market of about $25 billion (US). Eighty-one percent of the European stone production comes from southern European countries, namely Italy, Spain, and Portugal. Nowadays, about 60,000 companies work in the stone sector (including marbles, granites, and slates) in Europe, employing more than 500,000 people. In the U.S. the stone industry is also in good health according to a market study published by the trade magazine Stone World (January 2006). According to this study a total of 75 percent of companies saw increased business last year and 50 percent of all stone fabricators saw their business increase by a factor of more than 20 percent. The goal is to maintain the growth over the next 10 years. The U.S. is the biggest customer of natural stone after China, ranking 11th in the producers’ world list.

From the first manipulations in the quarry, the stones follow different steps up to the production of the slabs or tiles ready to be commercialized. It is outside the scope of this article to give a detailed report of the different steps, but in general the process comprises extracting big blocks from the quarries, squaring the blocks, sawing the blocks using gang-saws or big disc-saws to obtain slabs, surface treating the slabs, and cutting them to the final sizes. In most cases rocks are being mined the way it has been done for years and the manufacturing is mainly manual, usually carried out in conditions of powder and noise. This fact is threatening the leading position of the southern European countries because the emerging countries have labor costs significantly lower in this sector. According to the 2006 edition of the Annual Natural Stone in the World report, the average cost per hour in this sector is $17 (US) in North America, $13 (US) in south Europe, and just $0.3 (US) in China. Therefore, European stone manufacturers are exploring new methods to improve the machining of natural stone, reducing manual labor and creating a unique way to endure.

One example of this research effort is the study of the use of lasers to drill stone slabs, which was carried out at the University of Vigo (Spain) sponsored by the European Union, the Spanish Government, and in conjunction with the local stone manufacturers. Holes are needed to fix slate tiles onto a wooden frame to make a roof capable of withstanding the most severe weather conditions. In the last few years a new application of stones has gained substantial importance among architects and building constructors. This is the use of stone slabs in ventilated façades. Ventilated-type façades were developed to protect buildings against the combined action of rain and wind by counterbalancing the effects of water beating on walls and keeping the building dry, with high level aesthetic characteristics and undisputed advantages of heat insulation and soundproofing. In this application, holes are made on the granite slabs to clamp them because in these types of façades there is no mortar used to fix the slabs to the wall. The drilling step is done at the end of the process and must be done precisely and carefully in order to preserve the integrity of the processed granite slab. Therefore there is a need to improve the overall yield of this particular drilling process assuring accuracy in the positioning of the holes, in the high speed, and in the mechanical integrity of the stone pieces.

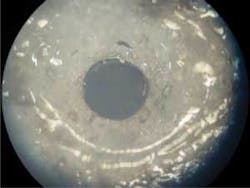

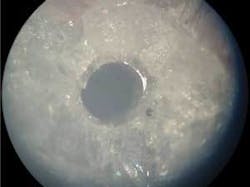

In contrast to polymers or metals, natural stones have an extremely high boiling point. Therefore the laser drilling process consists of heating the stone with the laser to melt the irradiated material and drag it out by a gas jet (usually compressed air) as depicted in Figure 1. This process is called “multishot percussion drilling.” In this technique there is no relative movement between the workpiece and the laser beam. Despite the uncertainties caused by the intrinsic inhomogeneity of a natural stone, reliable correlations have been observed between the geometrical characteristics of the hole and various process parameters. In this pulsing method of drilling the energy per pulse is a key factor. As a general tendency, increasing the pulse energy from 2 to 20 J per pulse, results in a 50 percent reduction in the number of laser pulses required for complete drilling of slate tiles. Figure 2 shows the aspect of a hole 1.5 mm in diameter drilled in a commercial granite slab 10mm thick. Using a 1kW CO2 laser, this hole is obtained in two seconds, which is 10-30 times faster than using a mechanical drill.

null

FIGURE 2. Shown is the aspect of the entrance and the exit of a hole 1mm in diameter drilled with a CO2 laser at an average power of 1 kW in two seconds. The granite slab is 10mm thick. The difference between the inlet and outlet diameters is 0.03 mm.

In laser drilling, as well as in laser cutting processes, the assist gas contributes to increase the effectiveness of the process by extracting the molten material from the interaction zone. The results of the experiments performed to study the role of the assist gas pressure in drilling natural stones show that at more than 1 bar the gas pressure does not represent a significant influence in hole diameter dimensions. Although under these experimental conditions (using a conventional conical coaxial nozzle at 1 mm from the stone slab surface) higher pressure should lead to an increase in pressure in the interaction zone.

Due to the high temperature achieved in the interaction zone of the laser beam with the stone, most of the minerals forming the granite (that is, mica, feldspars, and quartz) are molten. Therefore a thin impervious layer is formed inside of the hole (see Figure 3). This impervious layer seals the hole wall giving an additional protection to the stone slab especially when the slab will be used for external coverings as façades susceptible to frost, thus preventing them from cracking.

FIGURE 3. Viewed under an electronic microscope, the cross-section of a hole drilled in a granite slab shows an amorphous impervious layer that is formed along the hole wall.

Comparing laser drilling to mechanical drilling there are several factors that should be taken into account. The capital investment is highly favorable to mechanical drills. Also the running costs are advantageous to the mechanical tools. Notwithstanding, the availability of new sealed CO2 lasers that are more powerful and rugged, and require less maintenance, this is actually narrowing the gap in this particular aspect. But laser drilling systems offer several advantages when compared to their mechanical competitors. There is a significant reduction of time when using the laser (10 to 30 times faster). Additionally, the lasers have more process flexibility than the mechanical drills. Perhaps the main advantage is the absence of chilling liquids when using the laser. A mechanical drill consumes around 20-40 liters per minute. Nowadays water is becoming an expensive resource, especially due to the environmental regulations endorsed by the governments and agencies.

Reading about making a hole in a rock with light seems more appropriate to a Flash Gordon comic than for a technical journal, but this is real today and is made possible because of laser technology.

Acknowledgements

The authors wish to thank the European Union and the Spanish Government (FEDER/CICYT, DPI2002-02864) and Xunta de Galicia (contracts INFRA 94-68, PGIDT 03PXIC30309PN, PGIDT 01PXI30308PR and PR405A2002/11-0) for their support.

The authors are at ETS Ingenieros Industriales, Dpto. Física Aplicada, Universidad de Vigo, Lagoas-Marcosende 9, 36280 Vigo, Spain. Contact Juan Pou at [email protected].