Successful manufacturing of medical devices requires an in-depth understanding of the weld process, a highly stable laser source, and, most importantly, an integrated solution that incorporates the laser, software, motion, vision, and tooling with a proven weld process. We recommend obtain all these resources from a single vendor.

Medical product designers continue to create smaller and more advanced medical devices. When it comes to laser welding these devices, both the manufacturer and the laser supplier are presented with entirely new challenges such as achieving reliable and repeatable micro-welds that can be as small as 35 microns in diameter, and may also be mechanically delicate. Catheters and guide wire assemblies, for example, are typically fabricated from Nitinol or 304 stainless wire with an outside diameter of 50.8-127 microns. Flat ribbon wire used in some emerging medical applications may be only 25.4 microns thick; and wire coils with an ID of 127 microns are common in many new products. These products may have varying dimensions along the length, which may be up to two meters. Alongside these micro-spot applications are classic seam welding applications such as the hermetic sealing of implantable devices—applications that are being pushed more toward automation and reduced cycle times.

The major challenge to the system vendor is to create a timely and cost effective custom solution for each application.

In the area of medical device welding, the pulsed Nd:YAG laser still represents the best laser solution, offering unrivalled spot welding performance and minimum heat input seam welding.

Laser welding of medical devices appears to fall into two categories, macro-scale seam sealing and micro-spot. Defining macro and micro is somewhat of a gray area: anything smaller than a 200-micron spot size can be considered micro. Above this size, single-element focusing optics and standard 400-600 micron core diameter fibers can be used—these fibers are easy to launch into and have no power handling limitations. Below 200 microns, multi-element focusing optics is necessary, as well as smaller, more sensitive fiber core diameters (100 and 200 microns).

Macro applications typically fall into two categories: implantable devices and end-effector attachments for surgical tools. These applications require excellent weld quality with minimal heat input. Seam welding of implantable devices typically requires 300-600 micron core beam delivery fibers to provide maximum process stability and weld speed. The key in these particular seam welding applications is the integration of motion with laser control to create the contour weld, such that the pulse repetition rate is tied to the speed, and weld nugget spacing and energy input are consistent. The pulsed Nd:YAG is ideally suited to this form of control. The end-effector's attachment is usually a fillet weld requiring smooth transition between the two material thicknesses, such that no dirt or debris can accumulate.

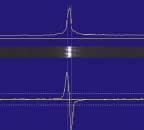

Micro-welding applications present a greater welding challenge. Reducing spot size, and therefore rapidly increasing peak power density, is great for drilling applications but presents significant obstacles for welding. Furthermore, when creating micro-welds, methods of heat sinking and means to avoid material balling around the joint are critical. Balling occurs when the joint material simply melts and forms a ball under surface tension pulling away from, rather than wetting, the other interface. For these applications the laser needs to operate around 100-500mJ, and down to as little as 20mJ.To ensure process stability the laser must offer excellent pulse-to-pulse stability. This is achieved by employing real-time power feedback during the pulse that, in turn, ensures that each pulse from warm start or cold, at the start of the flashlamp life or the end, is consistent.

In most cases, the welding process is qualified by producing prototype parts using basic tooling and fixturing concepts. This may involve several iterations to achieve a stable process but must be completed timely, as the manufacturer usually requires the system to meet FDA qualification and production schedules.

The system

Laser welding systems used for manufacturing medical devices are generally automated and require custom software, motion, vision, and tooling.

The software development has two parts; the graphic user interface (GUI) and the underlying code. The GUI must also provide a method for SPC and FDA data collection. The GUI, and the control code require the user and supplier to define functionality and precisely how and what needs to be seen and controlled. This process can be lengthy, but a laser system supplier can reduce this time by working closely with the manufacturer to understand each step in the process.

The motion system encompasses the required positional accuracy and repeatability and the orientation of tooling and support structures to allow sufficient accessibility for welding and loading. For instance, welding nested guide wires requires a direct drive system for speed and positional accuracy. However, seam welding a surgical tool end-effector only requires open loop steppers. A vision corrected motion system is often an essential component in medical laser welding systems. It can offer correction in all three orthogonal axes within a pre-determined "field of view interest" based on stack up tolerances. The lighting for the vision, along with software configuration of what is expected to be seen, is critical to the system reliability.

Once the device manufacturer has taken delivery of the laser welding system, the role of the supplier shifts to support. This has been made considerable more convenient by the use of emote diagnostics via PC and modem connections, which permit the laser system supplier to take full control of the system, with permission of the customer, to monitor and implement modifications directly. Motion programming, vision, and weld process parameters may be modified or diagnosed from a remote location.

Geoff Shannon, Ph.D. | Director Strategic Marketing for Precision Manufacturing, Coherent

Geoff Shannon, Ph.D., is Director Strategic Marketing for Precision Manufacturing at Coherent (Santa Clara, CA) and an Editorial Advisor to Industrial Laser Solutions. He previously served as Laser Technology Manager for Miyachi Unitek, specializing in the development of lasers and applications for existing and new markets. Shannon has a BEng in Mechanical Engineering and PhD in Laser Welding Technology from the University of Liverpool. His 20-year career in laser technology has centered around applications research and development and new product development of lasers and systems.

Craig Marley | Director of Business Development, Laser & Systems Division at Unitek Miyachi Corporation

Craig Marley is director of business development for the Laser & Systems Division of Unitek Miyachi Corporation (Monrovia, CA).