The inability to produce high-quality fillet and butt welds in thin (<2 mm) titanium alloys has limited the fabrication of these structures for aerospace and military applications. The problem is related to the instability of the molten weld pool that occurs in pulsed gas metal arc welding (GMAW-P) at higher processing speeds and subsequent lower heat inputs. The use of autogenous laser welding can be accomplished in titanium but fit up and equipment cost are prohibitive. Other researchers have investigated hybrid welding (laser with GTAW, GMAW, or PAW) of titanium alloys but their efforts have focused primarily on the use of high-power lasers to achieve very high production rates.

Recent investigation at Edison Welding Institute (EWI) has determined that a low-cost hybrid welding system can produce high-quality welds at low heat inputs. The approach uses low laser powers (~200 W) to stabilize the location of the cathode spot in the weld pool, which greatly improves the weld quality. By using a low-power laser with a GMAW-P system, it may be possible to greatly decrease titanium fabrication costs for aerospace, petrochemical, medical, and defense manufacturers.

The high specific weight, excellent corrosion resistance, high temperature performance, and bio-compatibility of titanium make it attractive to many different industries (aerospace, defense, petrochemical, and medical).1,2 Typically these structures are either machined from cast, wrought, or forged materials, or are conventionally welded with high heat input/high distortion processes. GTAW welding produces acceptable welds but it is slow and uneconomical.3 GMAW may increase efficiency and decrease cost but can not produce high-quality welds at higher processing speeds.1,3,4 The drawbacks of GMAW and GMAW-P processes are related to the instability of the arc and the cathode spot location in the weld pool at higher processing speeds.

The combination of laser beam welding (LBW) with either GMAW or GTAW is referred to as hybrid welding. Hybrid welding has been extensively investigated on a wide range of materials over the past few decades.5,6,7 Most hybrid welding research has utilized high laser powers for increased travel speed and penetration.8,9,10 While hybrid welds appear stable, there has not been any work to investigate the laser conditions that make the GMAW-P stable. If the GMAW-P process could be stabilized with a low-cost laser system, then the utilization of titanium fabrications may increase.

Experimental work

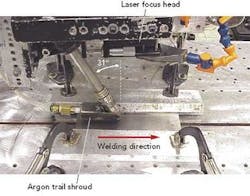

A dramatic change in the weld quality was observed when laser power was added to GMAW-P welding of titanium. This work was accomplished with a Lincoln Electric GMAW-P power supply and a TRUMPF/Haas Nd:YAG laser. The lamp-pumped laser can deliver 4 kW in CW mode through a 0.6mm diameter fiberoptic cable. For this effort, a four-axis CNC table produced the motion; the laser focus head and GMAW-P torch were mounted to the z-axis. The laser focus head was at 90º and the torch at 31º from vertical. Bead-on-plate welding trials were performed on 6.35mm-thick Ti-6Al-4V by translating the plates in the x-axis. A Lincoln Electric wire feeder was used to feed 0.889mm diameter ERTi-5 wire to a Binzel torch. The gas cup and a 50 × 60 mm trail shroud supplied pure Argon at a flow rate of 65 CFH (see Figure 1). Figure 2 (top) shows a typical bead-on-plate GMAW-P weld made at 1 m/min. A range of laser powers was investigated in order to stabilize the weld. Figure 2 (bottom) is the result of the same GMAW-P parameters with 200 W of laser power. The ability to stabilize the weld pool at such a low laser power was unexpected.

Figure 2. (top) GMAW-P; (bottom) Ti-hybrid, 200W; both welds at 1 m/min.

To determine the operational range of the stable process, a test matrix was performed. High-speed video (HSV) and data acquisition (DAQ) monitored the process and were used to help determine when the process was stable. The HSV and DAQ acquired data at a rate of 12,000 and 24,000 times per second, respectively. Various focal lengths (100, 150, and 200 mm) were used to produce a range (0.3, 0.45, 0.6, 3.18, and 5.58 mm) of focus spot sizes. Laser power was adjusted for these spot sizes until the arc was stabilized. The HSV captured "wandering" of the cathode spot in the weld pool as indicated by the small, bright spot in Figure 3a. In these images, the cathode spot has moved to the right edge of the weld pool (-0.68 ms prior to the application of the peak current), creating an irregular weld bead shape at that location. The arc column originated and grew from the cathode spot toward the molten wire. Once the droplet was fully incorporated into the weld pool, the cathode spot relocated itself in the weld pool. By contrast, Figure 3b shows a cathode spot that is rooted to the focused laser beam at the front and center of the molten weld pool. The arc column has a uniform shape, and the cathode spot did not move during any part of the waveform. This stabilization explains the results that were displayed in Figure 2 (bottom).

When "stability curves" were plotted as a laser power versus spot size for two speeds, the results indicated a minimum point (see Figure 4). This seems to indicate that a stable arc is not solely related to power density. Also, as the processing speed increased, the minimum required laser power increased by 50 to 200 W at the same spot size (see Figure 4). This suggests that a critical temperature (or amount of laser energy) must be maintained for a given laser spot diameter to achieve stabilization. However, the increase in laser energy input does not appear linear with the increase in travel speed.

Discussion and summary

The results indicate that it is possible to use a low-power, low-cost laser with GMAW-P to make high-speed, low-heat-input welds on titanium alloy structures. This could have a major impact on economic decisions concerning machining versus fabrication of components for a number of different applications. By using a low-power, low-cost laser, it may be possible to economically produce high-quality, low-heat-input fillet and multi-pass welds in these alloys. This could drastically decrease the fabrication cost for the structures making it more appealing to use titanium materials not only in aerospace and military applications but also automotive and consumer products.

While this investigation has resulted in a number of important conclusions, additional efforts are needed. A better understanding of the relationship between the laser spot size, energy input, and cathode stability is needed to determine the limitations of the approach. Further, with this understanding, it may be possible to transfer this approach to other alloys where such stabilization has not been noted at low laser powers. Additionally, because the laser power is low and the laser spot size large, it may be possible to use lower-cost diode lasers or even focused "white light" to produce similar results.

The authors are all with EWI, Columbus, OH. Paul Denney can be contacted by e-mail at [email protected].

Acknowledgements

Funding for this effort has been provided under the Ohio Department of Development, Technology Division, Agreement No. TECH 04-006.

References

- ASM Handbook, Welding Titanium Alloys, Vol. 6.

- Crowly, G., "Low-Cost Titanium," Advanced Material Processing, November 2003, pp. 25–27.

- Zhang, Y.M. and Li, P.J., "Modified Active Control of Metal Transfer and Pulsed GAMW of Titanium," Welding Research (Supplement), February 2001, pp. 54s–61s.

- Eickhoff, S.T., and Eager, T.W., "Characterization of Spatter in Low-Current CMAW of Titanium Alloy Plate," Welding Research (Supplement), October 1990, pp. 382s–388s.

- Dilthey, U., Lueder, F., and Wieschemann, A., "Technical and Economical Advantages By Synergies in Laser Arc Hybrid Welding," Journal of the International Institute of Welding, 1999, Vol. 43:141–150.

- El Rayes, M., Walz, C., and Sepold, G., "The influence of various hybrid welding parameters on bead geometry," Proceedings from Gas Metal Arc Welding for the 21st Century, December 6–8, 2000, pp. 1145–154.

- Eboo. M, Steen, W.M., and Clark, J., "Arc augmented laser welding," International Conference of Advances in Welding Processes, May 9–11, 1978, pp. 257–265.

- Aybe, N., et. al., "High speed welding of thick plates using a laser-arc combination system," Transaction of JWRI, 1997, Vol. 27 (1).

- Jokinen, T, Viherva, T., Riikonen, H., and Kujanpaa, V., "Welding of ship structural steel A36 using a Nd:YAG laser and gas-meal arc welding," Journal of Laser Applications, 2000, Vol. 12 (5): pp. 185–188.

- Hyatt, C.V., et. al., "Laser-assisted gas metal arc welding of 25-mm thick HY-80 plate," Welding Research Supplement, July 2001, pp. 163–172.