Cutting thick steel plate

New developments, including the use of fiber delivery and high-pressure oxygen assist gas, make the Nd:YAG laser an alternative for cutting thick mild steel plate

The laser used for cutting steel plates (up to 25 mm thick) is predominantly CO2, however, more recently the Nd:YAG laser is becoming an industrial performer in this area. Following a report at ICALEO 2003, it is now possible to obtain high-quality cutting of mild steel plate to 50 mm thickness using a fiber-delivered Nd:YAG laser at incident powers as low as 500 W. This is done by using the Lasox process, reported in Industrial Laser Solutions (January 2003 and June 2004), and by exploiting the material removal capabilities of high-pressure oxygen assist gas. The authors conducted this work at IRIS, Swinburne University of Technology, with the support from the Cooperative Research Center for Intelligent Manufacturing Systems and Technologies, Melbourne, Australia.

The advantages of using this process with a fiber-delivered Nd:YAG laser compared to using the CO2 laser are the better positional stability of the laser spot, the more divergent laser beam and higher absorptivity of the Nd:YAG beam by the workpiece, which allows a better utilization of the beam at lower powers. This technology is well suited to laser job shops that cannot justify the purchase of a higher-power laser but want to increase the thickness of mild steel plate that can be cut. In addition, the technology would also enable them to reduce subcontracting of thick-plate work to plasma, oxy-fuel or water jet cutting job shops.

In short, the technology increases the capability of an existing Nd:YAG laser without major changes required to the laser optics and gas delivery system and without a significant capital outlay. The use of an optical fiber to deliver the laser beam opens new opportunities for in-situ robotic cutting of thick-section 3D structures.

This follows several years of research by the authors on a new "add on" Nd:YAG laser cutting head that adapts the beam and also delivers either low-pressure (up to 120 kPA and termed "LoPOx") or high-pressure (up to 700 kPa and called "HiPOx") oxygen assist gas for cutting thick mild steel plate. In each case the laser beam is highly divergent with the spot incident on the workpiece surface larger in diameter than that of the co-axial assist oxygen jet.

This type of cutting uses the laser as the initiator of the cutting process (the laser preheats the surface to about 900° C), which is predominantly fueled by the exothermic reaction of the steel with the oxygen assist gas. Consequently, the control of the oxygen assist gas dominates the quality and nature of the cut and kerf shape. This approach has allowed the use of a relatively low-power (~0.5 - 2.0 kW) fiber-delivered Nd:YAG laser to cut mild steel plate between 20 and 32 mm in thickness with LoPOx and between 32 and 50 mm thickness for HiPOx.

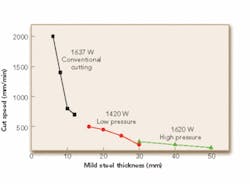

Figure 1 shows the compiled cut speed results for the two thick plate processes and conventional cutting of thinner mild steel plate with the Nd:YAG laser. This demonstrates that despite the novel approach to cutting with LoPOx and HiPOx the cut mechanism is similar.

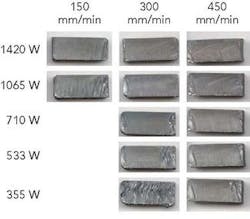

Figure 2 shows the high-quality cut surface that can be obtained by using LoPOx cutting as well as the incident laser powers and cut speeds for 20mm-thick mild steel plate using a 3.5mm diameter co-axial nozzle. Here, the critical issue is laser power level at the initiation of the cut, with first indications of insufficient laser power being the poor quality of the resultant surface at the beginning of the cut, which improves as the heat generated within the kerf conducts towards the top surface of the workpiece. Kerf widths are typically 2.5 to 3.5 mm with a taper of two to seven degrees.

Figure 3 shows a profile cut and surface finish for 40mm-thick, 250 grade mild steel plates cut at 150 mm/min. using HiPOx. The surface is very smooth compared to conventional cutting, with little or no oxide and a perpendicular top edge. Using HiPOx cutting there is large clearance (2 - 4.5 mm) between the co-axial nozzle and workpiece, increasing nozzle lifetimes and reducing the possibility of collision and damage. Kerf widths are typically 2.5 to 3.5 mm with tapers of two to three degrees.

An important aspect of profile cutting is piercing. Piercing of thick steel plate using HiPOx is very quick, with the 32mm thickness pierced in less than one second—compared to the typical 12 seconds necessary for an oxy-fuel system. This increases the possibility of laser profile cutting internal shapes within a thick plate. Figure 4 shows the piercing of 32mm thick, grade 250 mild steel plate with the resultant pierced hole seen in cross section. During piercing there is a significant amount of dross ejected upwards that can later inhibit the cutting process by sitting on top of the plate. Consequently, novel methods are required to ensure that the top surface of the workpiece is kept clear after piercing and that the co-axial nozzle itself is also kept clean.

The flow of high-pressure oxygen gas within the kerf generates small shock features, which are seen when viewing the melt stream. These leave small marks on the otherwise smooth cut surface; however, they can be easily controlled and minimized by optimization of the cutting parameters.

Research activities are currently directed at determining the optimum laser cutting conditions for a range of mild steel thickness, improving the cutting head design and material piercing. This work in laser cutting is part of IRIS's strategy to develop new processes and industrial applications for lasers.

James Harris and Milan Brandt ([email protected]) are with the Industrial Laser Applications Laboratory of IRIS, Swinburne University of Technology, Hawthorn, Melbourne, Victoria. Australia.