Finding focus in high-power industrial laser processes

In today's economic climate, those working with industrial high-power lasers should be doing everything they can to maintain one of their most valuable tools at its peak performance and optimize the processes for which they are used. As technology progresses, more techniques are available to laser users to optimize the application of their lasers, with the goal of maximizing throughput and minimizing downtime. Laser output power, along with focused spot size and its temporal location, are crucial to optimizing the laser process.

Material processing is an idea as old as time itself; however, using a laser for joining, cutting, ablating, etc. is something that is relatively new to mankind. Several different lasing techniques have served well over the past few decades, but it is no secret that the fiber laser, with its high wall-plug efficiency and high beam quality, has changed the way we produce parts with a laser. But two things have not changed with the introduction of the fiber laser: the high power densities needed for different results in material processes and the need for process control.

The concept of power or energy density is the amount of power (when discussing continuous-wave [CW] or average-power lasers) or energy (when discussing pulsed lasers) concentrated into a certain amount of space. For example, a 4000W laser focused down to a 100μm diameter spot size will yield a power density of approximately 51MW/cm2.

The power density that the laser yields determines the result of the interaction with the material. For instance, the ablation of plastic requires a much lower power density than the cutting of 1-in.-thick steel because of how the laser interacts between these two materials.

Focus shift

As the demand for laser powers continues to increase for industrial applications, the problem of stresses on the components within the laser system becomes more prevalent. One of these is the specific problem known as "focus shift," which is caused by thermal effects on the laser's components—specifically transmissive optics, such as focusing lenses and protective cover slides. When the focus shifts for the same distance that the laser's processing head is to the material, the power density changes; this causes a change in the way that the laser interacts with the material. Determining exactly where the focused spot is with respect to the parts being processed is crucial in many industrial laser applications.

To ensure a consistent process over time, the spot size must be measured to control performance. Most laser users working with material processing will agree that measuring the laser's power and spot size are important when developing a process. However, the reputation of the fiber laser's high-quality beam has lulled some laser users into thinking that process control is not as important once the laser is put into production.

The simple fact is that regardless of the lasing medium, the laser is still made of matter and matter degrades over time. Combine this fact with the relatively hostile environments in which industrial lasers are used and the result is a laser system that changes over time. These changes cause losses in laser power delivered to the work piece and changes in thermal effects that the laser light has on its components. Only through a rigid process control routine can the laser user better predict when to take maintenance actions on his laser system to keep its process optimized for peak performance.

Laser power measurement

Historically, laser power measurement suppliers have been able to supply laser users and technicians with power meter systems that are easy to install inside work cells, integrate directly into logical environments, remain protected from laser processing debris while not in use, and are easy to maintain and keep calibrated. These meters provide periodic measurements that are an effective way to determine the consistency of laser performance over time for the purposes of maintaining laser quality, improving maintenance schedules, and troubleshooting.

Many production environments and the debris that is produced during their processes are harsh on laser systems and can quickly and significantly reduce laser system efficiency. Process debris settling on the processing head's protective cover slide alone can reduce laser power to a point where the quality of the parts being produced is greatly diminished. Laser power measurement is the best first step to ensure that the laser is performing consistently over time. However, given the phenomenon of focus shift, a laser's power measurement will only tell part of the story. For this reason, laser measurement suppliers also have two techniques that are used to determine how large the focused spot is and where the focused spot is with respect to the processing head so that the desired laser power density can be maintained at the work piece.

At-focus beam measurement

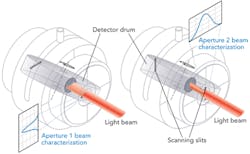

Scanning slit profiling systems, such as Photon's NanoScan products, are an accurate way of quickly determining the size of your focused spot (FIGURE 1). A spinning drum rotates two orthogonal slits around a single-element detector to incrementally expose the laser. The position of the drum interfaces with an encoder to tell the position of the drum, accurately reconstruct the size of the laser, and even mathematically represent 2D and 3D profiles of the laser simultaneously. The advantage of this method is that since the laser is incrementally exposed, the relative power density of the laser being profiled without any attenuation is high. Scanning slit profilers can be put directly into the beam path to image the focused spot of the laser—usually up to about 1000W of laser power (depending on the size of the focused spot). Using this method, the laser user can place his focused spot at the point of measurement without sampling or absorbing the beam to ensure that it is the correct size and that it is not changing over time. The laser user can also quickly and easily determine the best distance between the laser system and the part being processed.

One situation in which this beam measurement technique is useful is with the processing of medical devices. Measurement of the focused spot (in addition to at-process laser power) is crucial and sometimes even required during application development, system runoff, and continuous process validation. Since access to the laser's beam path after the laser is integrated into a system and put into production is often limited due to mechanical interferences, sampling the beam for purposes of attenuation is usually challenging. Since scanning slit profilers have a small footprint and require no attenuation, using them to measure the focused spot on CW or quasi-CW beams has been successful.

Non-contact beam measurement

Recently, Ophir-Spiricon released a camera-based, non-contact beam profiling system called BeamWatch, which provides multi-kilowatt, 1-μm-wavelength laser users with data never before seen with any beam profiling system (FIGURE 2). The signal supplied to and analyzed by the product is based on a physical property of light known as Rayleigh scattering, where the high-concentrated light around the laser's beam waist is scattered off air molecules in its vicinity and captured by the camera. This allows for an analysis of the laser's waist without coming in contact with the beam. The result is a beam analyzer with no water cooling required, no moving parts, and no upper limit in the power of the laser being analyzed. And since it is a camera-based system, it provides data up to 15 times per second to allow users to see more time-based characteristics of their laser systems.The system includes software designed for the laser technician that provides measurement of laser spot (or "beam waist") size and the location of the spot over time. Laser users can measure and graph how much and how quickly the spot shifts to better characterize their laser system. In non-contact beam measurement, the camera coupled with a telecentric lens is viewing the laser's Rayleigh length, which is not only the focused spot, but the beam path above and below the focused spot. As a result, beam divergence, M2, and beam parameter product (BPP) measurements can be provided in real time. The system also includes an optional, simplified "user interface" that displays green and red Go/No-Go readings on key laser parameters based on predefined user specifications for quick periodic checks of the overall laser system.

Many industrial laser applications that use multi-kilowatt lasers rely on measurement of the focused spot size and location to ensure correct and consistent laser power densities. It wasn't until the release of BeamWatch that laser users had a way to measure these laser parameters. For instance, during some automotive welding applications, processing happens not at focus, but some distance past focus since a relatively larger beam with a lower power density produces desired results. If the focused spot is shifting due to thermal effects on the laser system after the beam is turned on, the location of the focused spot is not constant and therefore the power density of the beam changes, resulting in an inconsistent result over the duration of the weld.

Another laser application where the location of the focused spot is critical is laser drilling for aeronautical and aerospace part production. During these processes, thousands of tiny holes are drilled into parts for purposes of air-cooling parts, which would otherwise be destroyed or deformed during use. Lasers with extremely high peak power and relatively long focal length lenses are used to drill these holes. The location of the focused spot—where the laser's power density is highest—must be determined and strategically placed onto the part being processed so that each hole is consistently drilled, both from top to bottom of each hole, and from hole to hole. Maintaining the location of the laser's focused spot has historically been a challenge since there has not been a way to dynamically measure this laser characteristic. Non-contact beam measurement provides a solution to this problem.Reflective optics at high powers

Recent advances in beam delivery systems have led to new ways to deal with the problem of focus shift. Laser applications specialists have used Spiricon's non-contact beam analyzer to help develop these advanced products. One design characteristic that helps with this problem is the application of reflective optics instead of transmissive optics, which are more susceptible to thermal effects from the laser. As laser powers continue to climb, they are applied to industrial processes. Recently, measurements were made with Spiricon's BeamWatch system on a 100kW fiber laser being focused with reflective optics (FIGURE 3). Due to the relatively high laser power, this processing head exhibited an approximate 8mm focus shift from beam-on time to approximately 20 sec later (FIGURE 4). The fact remains that lasers will continue to have thermal effects on the system components with which they are integrated.The past few years have taught us all to do more with less. Industrial laser users and those who support their efforts are in no way exempt from this. More and more pressure is being put on production facilities to optimize their processes, increase their throughput, minimize their downtime and operational costs, and reduce scrap. Thankfully, the laser user and the laser technician have more tools than ever before to maximize the efficiency of their laser and to keep their laser processes consistently high-quality. In addition to utilizing the latest technologies in laser systems to accomplish these goals, the latest technologies can be used to better characterize and optimize the performance of these laser systems.

ACKNOWLEDGEMENT

BeamWatch is a trademark of Ophir-Spiricon.

John McCauley

John McCauley is senior business development manager for MKS Ophir, with a focus on automotive and directed energy applications. Previously, he served as their Midwest regional sales manager and product specialist for all markets. Since 1998, his background has been as an end user of, and an applications engineer working with, laser marking and engraving systems. He has also worked closely with several mid-Indiana metal fabricating customers.