FRANK GEYER

The terms hot stamping and press hardening are commonly known and used within the automotive industry. The benefits of using ultra-high-strength steels, such as 22MnB5, allow car manufacturers to build lighter, yet stronger and safer vehicles.

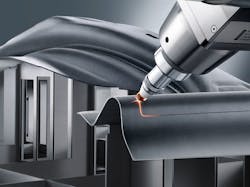

Press-hardening components made from boron steels requires several processing steps that result in high-strength parts. First, the blanked parts are heated to about 1740°F and then formed and quenched while still in the die, giving a characteristic martensite grain structure and the desired properties. While the structure of a car body outside the passenger cell is designed to deform and absorb energy, the hot-stamped components used in body-in-white (BIW) construction are intended to maintain shape to protect the passengers. A- and B-pillars, for instance, are typical components made from hot-stamped materials (FRONTIS).

However, this harder material comes with its challenges. Due to its properties, press-hardened boron steel cannot be conventionally trimmed with a die-cutting process, as the material is harder than the die steel. Here, the laser comes into play. With its non-contact and no-wear characteristics, it is the preferred tool for cutting and trimming these extremely hard parts.

Making steel stronger

Before the hot stamping process, the blanks for the components are cut from coiled material—an aluminum-silicon (AlSi)-coated boron steel with initial yield strength of 500MPa. In the first part of the heating process, the blanks then are heated to approximately 1200°F to allow the AlSi coating to bond to the boron steel base. In the second part, they are further heated to approximately 1740°F. The bright-red glowing parts are placed in the press dies, followed by forming and quenching within the die. Within a short period of time, the parts are cooled to about 400°F using rapid controlling. The result is an austenitic grain structure, which gives the parts a yield strength of around 1500MPa. While the process is often referred to as hot forming, the description of press hardening is actually more precise, as the entire process is a heat treatment. The forming alone could be done without the parts being heated.

With the parts formed, they need to be trimmed into their final shape and openings or holes need to be added. The high strength of the parts requires a different method than commonly used on other stamped sheet-metal parts. Trimming die material is not hard enough to allow its use for trimming or cutting hot-stamped parts. Even if this process could be used, it would still pose risks like deformation of the edges and micro-cracking due to the high forces involved. In addition, the cost of those tools would be too high to be economically viable, as they would require repair or replacement within several hundred hits. The downtime for the tooling changeover and its associated cost further reduce the usefulness of this process.

Knight of the Light

Since cutting steel with steel is no longer a practical option, the industry has turned to the laser. In the case of cutting thin sheet steel, the solid-state laser—with a wavelength of approximately 1μm—has been proven to be the best solution. When used as a cutting tool, the laser's high-energy beam melts the material and a high-pressure processing gas blows the molten material away from the cut. Contrary to some beliefs, the laser does not cut like a blade. Instead, the energy input into the material from the focused beam, combined with the high-pressure cutting gas, produces the actual cut. The advantages are significant, as the laser cutting process allows for a consistent quality (light has no wear). In combination with a high-performance 5-axis machine, the customer has a tool that provides high quality and efficiency. An additional benefit of such a laser system over a die cutting press is the ability to quickly adapt the processing geometry. The laser beam is guided through optics to the processing head, which can be positioned by a computer numeric control (CNC) program. A small change in the part design requires only a program adjustment, not a reworked die with its high cost and timing impact. The challenge, however, lies in matching the throughput of laser cutting with that of blanking. For any exterior trim or interior cutout, a laser cuts one contour after another while a die cuts all features in a single hit. High-power lasers, in combination with high-end laser systems, allow customers to address this issue efficiently.

Cutting speeds have increased significantly over the last decade. Almost 10 years ago, cutting a typical hot-stamped part—such as a B-pillar from a Volkswagen Passat—took two minutes to cut using a state-of-the-art system equipped with a 3.2kW CO2 laser. Today, the same part, with 22 holes and a total cutting length of 248in., is cut in just 47 sec—this time using a 3kW solid-state laser with high beam quality, advanced machine functions like piercing-on-the-fly, and increased machine dynamics.

Reduced cutting, faster handling

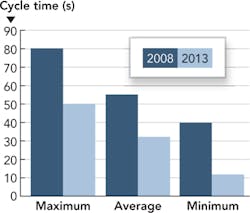

While laser processing is efficient and popular, customers attempt to use it as infrequently as possible. With pre-developed edges, most frequently found on parts with overlapping slip joints, the amount of laser cutting is reduced to a bare minimum. With a decrease of the amount of cutting necessary, the cycle times are reduced as well. This poses a unique challenge for customers, as the cutting systems are too fast for an operator to load and unload within the desired cycle time. This leads to a reduced utilization of the system as the laser system waits for the operator. Companies typically calculate approximately 40 sec for a total cycle with loading and unloading. The 2008 average cycle time for hot-stamped parts at around 55 sec is shown in FIGURE 1. This has been reduced to an average of only 32 sec in 2013.Less can be more

In addition to the speed of processing, the overall cost of manufacturing a hot-stamped part is critical to customers. While higher speeds seem to be the obvious solution for higher efficiency, the laser cutting process is more complex and other aspects need to be considered as well. High processing speeds require simple, as-straight-as-possible cutting geometries and high laser power. As most component geometries in a BIW construction do not fit this description, the notion of more-is-better does not apply. A complex 3D geometry limits the processing speed and, in turn, the amount of laser power that can be applied. While a 5-axis laser cutting system can reach straight-line cutting speeds of 1180in./min in 0.04in. steel with a 3kW solid-state laser, it rarely reaches this speed and power level when cutting a part with many directional changes. There, the laser power applied is often below 2kW—in tight corners, it is even less.

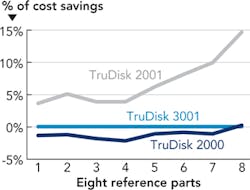

As laser power has an investment and an operational cost factor, this has to be considered an area for possible cost improvement. With the latest generation of higher-beam-quality, lower-power solid-state lasers (FIGURE 3), it is possible to reduce the cost per part with little to no increase to the cycle time. When comparing a 2kW solid-state laser to a 3kW version, the typical cycle time impact is 4–6 percent slower processing times. Going from a beam quality of 4mm*mrad to 2mm*mrad increases the processing speed capability at the same power consumption. With the lower investment cost and reduced energy consumption, a lower cost per part is possible when the fabricator chooses a 2kW laser with high beam quality over a conventional 3kW laser.Summary

Press hardening has become a commonly used process in the manufacturing of BIW structures in the automotive industry. These engineering solutions continue to mature and evolve, while the systems used for post-processing, such as laser cutting systems, have been able to keep up with the ever-increasing requirements for productivity and cost efficiency. Market requirements and the specific solutions available to fulfill them ensure that the use of lasers for cutting hot-stamped parts will remain the tool of choice and allow customers to stay competitive.

FRANK GEYER is Product Manager – Laser Systems for TRUMPF Inc., Plymouth, MI.