Automated hybrid laser welding combines with high-power laser cutting to produce a better process solution

EDWARD HANSEN

Hybrid laser arc welding (HLAW) using an automated seam welder, a high-power solid-state laser, and innovative adaptive process control technology, combined with conventional CO2 laser cutting, provides productivity, quality, and cost efficiency gains for thin-tank fabrication.

First introduced in 2006, ESAB's HLAW process offers impressive benefits: welding speeds three to five times higher than gas metal arc welding (GMAW), reduced heat input of up to 90 percent, and operational savings of approximately 50 percent compared to GMAW. HLAW has opened the door to new design approaches for products, reducing product weight and cost through use of high-performance lightweight alloys and advanced structure designs.

Today, a strong business case can be made for the use of HLAW in thin-walled tank and pressure vessel production. Thin-tank fabrication includes stationary and mobile storage tanks and pressure vessels made of mild steels, high-strength steels, and stainless and duplex steels, as well as aluminum alloys with thin, light structures having walls 16mm or less in thickness.

High-accuracy, clean-edge geometry

The first step in the automated tank manufacturing method (SIDEBAR) is flat sheet cutting. ESAB's process uses high-definition, large-format CO2 laser cutting to achieve part accuracy over long seam lengths required by hybrid welding for robust operation. Laser cutting machinery is substantially less expensive to acquire and operate than plate milling equipment, which has been previously used prior to laser butt welding operations. The high edge quality of laser cutting delivers predictable joint geometry with few process contaminants and a weld-ready condition. In addition, large-format laser cutting systems provide very flexible production capability that dedicated edge milling equipment can't offer.

ESAB's Alpharex laser cutting gantries—with working widths of up to 5.1m and no theoretical restriction in working length—eliminate beam divergence, which can be problematic over large work areas, and ensure that laser intensity and cut quality remain constant over the full work space. The cutting system's guidance achieves high accuracy at very high speed positioning and cutting rates. In this first operation, high part level dimensional accuracy with the correct, high-quality edge geometry required for advanced joining processes is cost-effectively achieved.

Longitudinal seam welding

In developing its new hybrid laser tank production process, ESAB teamed with partner company Deuzer Machinenfabrik (Deuma; Netphen, Germany). Together, the two firms developed an advanced, automated seam welding platform capable of performing longitudinal flat sheet and cylinder one-side seam welding of shells up to 8.5m long and as small as 1.07m in diameter. In a single weld pass, it is able to weld a wide range of carbon steels, stainless steels, duplex stainless steels, and aluminum alloys up to 12.5mm in thickness (FIGURE 1). Thicker plate joints can be accomplished with additional fill and cap weld passes.

The automated seam welder uses its length capability and high production speed to help tank designers shift from short cylinder segments with frequent girth seams to long cylinder segments with fewer girth seams. Longitudinal seams are much easier to automate and much less expensive to produce than circumferential girth seams. Shifting tank designs to take advantage of high speed, automated longitudinal seam welding over greater seam lengths with fewer manual/semi-auto girth seams both increases production rates and significantly reduces production costs.

On this unit, individually CNC-controlled multi-stage pneumatic clamping fingers along with pop-up alignment gauges are used to precisely align and clamp sheets in 3 axes without manual intervention. A specially designed, cooled backing bar with inert gas purge creates a very small, clean internal root bead, which can minimize post-weld surface preparation. The small cap and root bead make installation of internal baffles easier and improve tank coating and lining. They also make it easier to roll a perfectly round tank circumference.

For thin-tank production, this longitudinal weld process achieves:

- Higher welding speeds of 120 ipm (3 m/min) to 160 ipm (4 m/min);

- Larger tanks/shell sections with fewer girth joints/seams at assembly, making it easier to automate the production of large tanks;

- Rounder, smoother tank interiors, which improve down-stream installation and coating and finishing;

- Reduced opportunities for creating weld defects and weld repairs, as girth seams are the greatest source of weld defects in tank production; and

- Reduced intersections of girth and long seams, which reduces the need for inspection as well as the chances of creating RT defects and expensive repairs-the intersections of girth and long seams are areas often requiring x-ray inspection on pressure vessels.

Circumferential girth joint welding

ESAB and Deuma also collaborated on addressing the welding of girth seams on tanks and pressure vessels. Once the initial tank shells have been produced using laser cutting and hybrid laser welding, the precision can be achieved that is necessary to proceed to hybrid laser welding of circumferential girth welds.

ESAB's laboratory work on 1G rolled cylinder welding and fully orbital welding has demonstrated the suitability of the hybrid process for all-position girth joining. Deuma brings to bear their precision tank fixturing system, which is capable of aligning, positioning, and manipulating tank girth joints during the hybrid welding process. Their External Alignment System simultaneously squeezes the sections to eliminate shell ovality, aligns joint edges to eliminate mismatch, and compresses the weld joint to minimize gaps. This system then rolls the aligned shell sections on precision bearing surfaces to allow 1G rolled girth welding without the need for pre-tacking of the sections (FIGURE 2). The end result is a fully penetrated, single-pass girth joint on thin-tank walls or a deep, high-integrity initial root pass on thicker tank walls.

Advanced process control and quality assurance

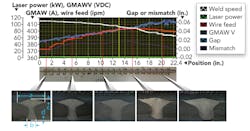

An advanced adaptive welding process control, developed by ESAB, broadens the process window for handling joint gaps and mismatch by a factor of five compared to conventional steady-state welding controls (FIGURE 3). The adaptive control and quality assurance system, part of the company's seam and girth welders, makes the HLAW process more cost-effective for thin-tank production, as it allows the use of conventional thermal cutting processes rather than plate machining to manufacture the tank shell. It also allows large-shell girth circumferences to be welded without expensive shell re-machining.

The hybrid laser process control is a three-stage system that looks ahead of the process, tracks the joint, measures the joint fit-up, monitors and adapts the weld process in real time, and looks behind the process for weld geometry measurement and automatic weld feature identification and measurement to produce uniform bead shape, uniform penetration, and acceptable weld quality over the entire weld length.

This 3-stage control system gives the hybrid welding system a process window that is 5X larger than comparable constant-control hybrid systems. In addition, a quality control module collects a meta-record for each weld seam, which includes information on the weld joint, the actual measurements of all essential weld variables used in the process, and the resultant weld joint surface quality. This is recorded in detail and reported with a statistical summary of the finished weld quality and identification and location of any and all weld discontinuities that occurred during the weld. Such level of comprehensive quality control can be an indispensable new capability for tank manufacturers, particularly those building pressure vessels.

In this process, the adaptive control system (FIGURE 4):

- Senses joint fit-up variation;

- Senses any movement in the joint during welding;

- Adapts essential welding variables during weld to match joint conditions;

- Monitors and maintains welding parameters within approved Welding Procedure Specifications (WPS); and

- Senses shape and quality of weld bead surface immediately after welding.

Better fit and finish on high-performance materials

Tank manufacturing using the combination of laser cutting, hybrid laser welding, and advanced automation control provides improved product fit and finish, and enables a shift to high performance/lighter weight alloy steels and aluminum to enhance product quality. This thin-tank fabrication method may also provide opportunities for premium margins and create a barrier for low-tech competitors.

Process cost reduction

The process cost reduction from the use of hybrid welding can be significant. Use of a deep 12.5mm hybrid laser square butt root pass reduces total joint volume by 80 to 90 percent compared with conventional welding on plate thicknesses up to 25.4mm. In addition, downstream savings by reducing distortion can be a major cost reduction factor. The downstream effects from distortion may be hidden, but are costly and can involve fitting, scribing, assembly adjustments, make-up pieces, and slotted fasteners, as well as post-weld layout, machining, and finishing treatments. A low-distortion joining process such as HLAW can reduce or eliminate non-value-added work, rework, and repair.

While investment cost is typically the primary barrier to adoption of HLAW technology, a look at the total impact of the technology to the production process, including plant throughput and overall production costs, reveals the true ROI. As laser costs continue to decline, direct-diode lasers begin to offer the beam quality and power level to be industrially relevant—as the laser form factor continues to improve, this technology will inevitably have a major impact on tank and pressure vessel fabrication. Hybrid laser welding already offers aggressive competitors a step change in efficiency, cost, and productivity for thin tank and pressure vessel fabrication.

ED HANSEN([email protected]) is Global Product Manager – Welding Automation with ESAB Welding & Cutting Products, Florence, SC, www.esabna.com.

Automated tank production enables:

- Improved rolling and shell roundness with small weld bead size

- Small 1mm radius of the weld root; ready for food-grade tanks with minimal additional preparation

- Improved over-coating with tank liners for longer coating life and lower warranty costs

- High travel welding speed of about 120–160 ipm (3–4 m/min); increased productivity in the seam welding operation allows the tank manufacturer to rebalance the welding process-shifting from girth seams to long seams-to increase overall throughput

- Pre-weld optical inspection and regulation of weld joints automatically performed by the adaptive process control to ensure proper fit-up for welding

- In-process adaptive control adjustable to joint location, which compensates for variations in fit-up gap and mismatch during the welding process, monitoring and adjusting these parameters on the fly to meet specifications

- Very smooth, flat, full-penetration, single-side welds are achieved, allowing tanks to be rolled perfectly round

- Precision square butt joint with no root gap opening and low heat input results in a precise tank diameter for improved installation of baffles, domes, and girth joints

- Replacement of manual fitting and semi-automatic girth welds with fully automatic long welds

- Reduced weld rework, grinding, finishing, and other secondary operations

- Improved product quality (coatings, cosmetics, roundness), which may bring a premium in market

- Higher plant throughput with more production from the same footprint