Diode lasers for remote welding

Lighter weight and less cost in auto manufacturing

TOBIAS STITTGEN, AXEL LUFT, and WOLFGANG TODT

For more than 13 years, diode lasers have been used in series body manufacturing. The first diode laser system was installed for brazing tailgates on the Audi A3 in 2001 (FIGURE 1). While today's diode lasers in car-body construction are the industry standard for brazing, cutting, and welding of aluminum and steel, a new promising technology in body shell work emerges: remote laser welding.

What are the main advantages/benefits of this technology? What are potential applications? How can fiber-coupled, high-power diode lasers create added value in body-in-white (BIW) remote welding applications?

The most common application in BIW construction is still laser brazing, where moderate beam quality is sufficient because the application is mainly a melting process. However, Laserline now offers diode lasers with considerably wider ranges of power and beam quality than required for brazing. In 2009, the LDF4000-30 diode laser was introduced; with an optical output power of 4000W at a beam parameter product of 33mm-mrad, this laser enabled welding and cutting in addition to brazing applications.

The latest model, LDF4000-8, was introduced in 2013. This diode laser, with an active converter fiber and output power of 4000W at a fiber diameter of 200μm, completes the top of the product portfolio and plays an integral role in remote laser welding.

These lasers are appropriate for any kind of application in body shell work, seating, and interior. The system is characterized by the robustness and availability of a diode laser, while increasing beam quality up to 8mm-mrad.

Since 2001, the number of end customers employing diode lasers in automotive manufacturing has increased continuously. As of 2014, more than 450 systems have been installed and most automotive companies use diode lasers for their series production.

Remote diode laser welding in body construction

Compared to traditional joining technologies such as resistance spot or arc welding, laser joining offers numerous advantages: low heat input, contact-free design, low wear, single-sided tool access, and high process speed in reproducible, robust processes.

Remote laser welding is characterized by increased flexibility, high operational speed, and a reduced cycle time, and complements the aforementioned advantages of laser joining.

In remote laser welding, the combination of a high-power, high-beam-quality diode laser, scanner unit, and robot system is essential (FIGURE 2). The scanning unit consists of focusing optics with a relatively long focal distance in combination with galvanometer scanning mirrors. This setup enables high-speed focusing of the laser beam onto the workpiece. In most available scanning systems, the focus position is not limited to a two-dimensional plane-an additional linear axis within the beam collimation enables any arbitrary 3D workpiece geometry.

This optical layout allows for extremely fast switching in between the desired weld joints, resulting in a significant decrease in laser off-time. Additionally, the long working distance allows for simplified clamping techniques and protection of the optics from weld spatter. To further improve workpiece accessibility and system flexibility, the scanning unit is attached to a six-axis robot.

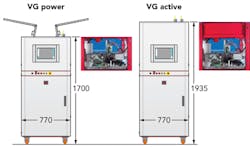

Laserline's LDF4000-8 fiber-coupled, high-power diode laser satisfies all requirements imposed by remote laser welding in BIW applications to a high degree: excellent beam quality and, hence, focus ability, simple integration, and an operational availability of more than 99.5 percent. While having identical spare parts, handling, and footprint as the company's other diode lasers, the active converter fiber version is only 12 percent higher and has a wall plug efficiency of 26 percent (FIGURE 3).

Remote welding of aluminum door flanges

In application trials, ThyssenKrupp System Engineering (TKSE) qualified Scanlab's intelliWeld scanner systems (FIGURE 4) and the HighYAG RLSK laser processing head (FIGURE 5) in combination with the new LDF 4000-8 diode laser. With a fiber diameter of 200μm and tri-fold aspect ratio, welding is carried out with a spot size of 0.6mm at a focal length of 500–600mm.

TKSE set up a door flange remote welding process to qualify Laserline's high-beam-quality diode laser in combination with the aforementioned optics. With remote welding, non-productive time between weld seams is minimized and laser utilization can be maximized. By using remote welding in applications like welding the inner structure of doors with a big amount of weld seams, this high utilization results in a significant decrease of equipment and in investment costs.

Additionally, single-sided access, a facilitated clamping process, and smaller weld flanges enable a completely new part design with regard to material mix, geometry, and weight.

Furthermore, remote welding allows welding of load optimized weld geometries and so called "knobs," which ensure a degassing gap when zinc-coated steel is in use. All these different possibilities were tried out at TKSE with the LDF 4000-8 and both scanner systems.

Added value in body work

As pointed out, diode lasers have gained significantly in importance during the last 13 years and are today's standard in all common BIW applications. In 2013, Laserline launched the LDF4000-8 with superior beam quality, surpassing state-of-the-art fiber lasers of comparable beam quality and power with regard to lifetime, stability, and modularity. The anticipated lifetime of a Laserline diode laser is 40,000 to 50,000h. This means that no replacement of diodes is necessary within a car model cycle.

Also, a strong synergy is created when combining a scanner unit guided by a robot and the new LDF4000-8: the gained flexibility promotes welding of different body architectures on one single production line.

However, flexibility is not limited to the welding process itself. Diode lasers are of small size and can be placed right beside the laser cell; that is, the use of very short fibers is feasible. The lasers are equipped with wheels and are not stationary. All connectors are equipped with plugs and if problems occur, the laser can be replaced on-site within 30min. Backup systems are recommended for high throughputs and high workloads, as exhibited by remote laser welding processes.

Summary

Lasers enable lightweight designs in cars, open new design opportunities, and yield cost reductions in car body work. Diode lasers are used in all common body work applications such as brazing, welding of steel and aluminum, and cutting. They have advantages concerning wall plug efficiency, are very robust towards backreflections in aluminum welding, produce low investment and operating costs, are very reliable, and are simple to handle when service is required. During the past 12 years, application potential and advantages have led to a large number of diode lasers in car body production. Today, about 450 lasers are used across the world in such applications and their number is still on the rise.

TOBIAS STITTGENand AXEL LUFT([email protected]) are with Laserline GmbH, Mülheim-Kärlich, Germany, and WOLFGANG TODT is the vice president of Laserline Inc., Santa Clara, CA.