Femtosecond laser processing of metal and plastics in the medical device industry

Microsecond fiber lasers have been used successfully for medical device applications in hypo tube and stent cutting for many years. While precise and fast, the downside has been that the parts require a number of post-processing operations after they are cut, which adds significantly to part cost and can also damage mechanically delicate parts.

In recent years, ultrashort femtosecond laser technology has been introduced, which produces pulses that leave no thermal fingerprint on the part. These disk-based femtosecond lasers offer sub-400fs pulses, plus best-in-class beam quality and peak power that enable an extremely high-quality cold ablation cutting process rather than a melt ejection process. Therefore, the resulting cut requires minimal post-processing and the smaller beam size allows machining of very fine details.

The process works especially well for production of such medical devices as catheters, heart valves, and stents, as well as in other medical glass cutting and marking applications and in 3D structuring of ceramic material for dental implants. But perhaps the most interesting potential use is on a whole new class of bioabsorbable materials—polymers that safely remain in the body for controlled lengths of time before absorbing, which are being developed as an alternative to traditional polymers or metal components.

In the past, femtosecond lasers have been considered too slow for commercially viable operations. Recent studies evaluated cutting time per part and post-processing steps, demonstrating that the return on investment (ROI) for a femtosecond disk laser can in many cases be less than 12 months, especially for high-value components. A key aspect of realizing the femtosecond laser's potential is the system platform; to this end, Miyachi America has developed both stage and scan head platforms that can fully unlock the promise of reaching this new level of quality and precision for micro treatment.

Femtosecond basics

Femtosecond light pulses are ultrashort pulses (USPs). One femtosecond equals 10–15s and, as a calibration point, a 300fs pulse equates to a physical length of pulse of only 90μm. Since there is no thermal processing as there would be in nanosecond pulses, USPs have many advantages:

• No heat impact, so there is no thermal tension in the material and no change of material characteristics;

• No shock waves, so there are no structural changes;

• No micro cracks for smooth, processed surfaces;

• No melting effects, so there are no structural changes;

• No surface damages, so there is no rework or after-processing;

• No debris, so no cleaning is necessary;

• No ejected material for clean surfaces; and

• No recast layer, so there are smooth edges.

FIGURE 1 illustrates these effects on an application using a long-pulse laser (for example, microsecond) compared to that of a USP laser like a femtosecond laser.

Femtosecond laser technology is not new, as it's been widely used in institutions and research centers for more than 30 years. However, commercially ready femtosecond technology that can last in an industrial environment with a 24/7 qualification has been around for about the past seven years. Originally used for wafer dicing and scribing of P1, P2, and P3 solar panels or creating channels in panels for electrodes, femtosecond lasers are now advancing into a new wave of machining capabilities and many medical devices are excellent candidates, especially given the high cost of the components machined.

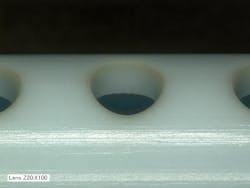

In addition to the ROI justification of minimized post-processing, the femtosecond disk laser can create unique features that were previously not possible due to quality concerns, particularly with processing polymers. FIGURE 2 shows the comparison of a nanosecond 355nm source and a 1030nm femtosecond disk laser source processing polypropylene. The appearance of the femtosecond disk hole shows little taper, no melting, or heat effect distortion around it. This enables product design freedom to maximize functionality with little or no compromise to the manufacturing process.Development based on ROI considerations

The edge quality possible with a femtosecond laser for both metals and plastics makes it excellent for machining of heart, brain, and eye stents (both Nitinol and cobalt-chrome); catheters; heart valves; and polymer tubing. The nearly cold cutting process means very fine feature sizes can be cut into the thinnest material while still maintaining mechanical and material integrity. No internal water cooling is needed for even the smallest Nitinol diameter tube.

Quality improvements and the promise of reduced post-processing has always made femtosecond laser technology a theoretical possibility, but until about six years ago there was little commercial interest in its use for medical devices due to concerns about the expense and slow speed compared to other technologies.

That changed when some companies, including Jenoptik, developed an ROI tool to illustrate the true cost of post-processing. The tool can be used to factor in overall costs, including laser equipment purchase, post-processing capabilities, machine time, and handling time. The calculations demonstrate that femtosecond lasers are actually faster because they alleviate several time-consuming post-processing steps.

Take the example of the ubiquitous coronary stent, one of the first devices to be manufactured with a fiber laser. The part has to be machined, then honed or cleaned out inside with a mechanical tool, and finally deburred. Then, a chemical etch process must be performed to clean up around the edges, followed by an electro-polishing step. Not only are these steps time-consuming, they can also cause the part to become brittle, deformed, and form micro cracks. Yields tend to be in the 70-percent range, meaning that a significant amount of end product is lost.

By contrast, the femtosecond laser is a dry format, meaning that no water or heat is introduced in the part. The number of steps is drastically reduced—the part is machined and then undergoes an electro-chemical process to round the edges. This results in improved part integrity, eliminates time-consuming steps, and enables yields closer to 95 percent.

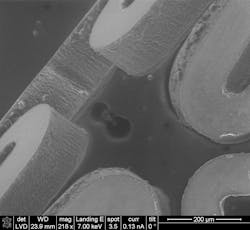

FIGURE 3 shows the high cutting quality of the femtosecond laser for cutting Nitinol stent material. The use of the femtosecond laser prevents burr and the slight roughness of the cutting edge gives a good precondition for the electro-polishing-process. Removal rate in this example was 0.25–5mm/s and material thickness up to 400μm is possible.The numbers definitely tell the story, as major medical device manufacturers are starting to understand the true ROI of more efficient machining technologies.

The femtosecond laser is also the only current technology appropriate for machining medical products out of new, bioabsorbable polymers, which can be safely implanted in the body for controlled lengths of time before absorbing without causing harm or adverse interactions. Next-generation advanced bioabsorbables (also called aspirants) provide an alternative to traditional polymers or metal components, and are being designed to meet precise degradation rates and other specifications.

The bioabsorbable material can be machined into any profile that can be used for stents. However, it must be machined correctly and without inducing heat. Failure to do so might lead to crystallization in the material, which would degrade its structure and affect its lifespan and ability to dispense medicine at the correct rate. Also, because bioabsorbables dissolve, they cannot be cleaned like most plastics, nor can they be touched with any liquid solutions—which is another reason that the femtosecond laser is a better choice for the material.

Bioabsorbables are already being used for coronary stents in the EU, although they have not yet received FDA approval for use in the US. Mostly composed of polyesters, primarily homopolymers and copolymers of poly (lactic acid) and poly (glycolic acid), bioabsorbables are showing promise for a variety of uses, including cardio stents for patients who may have been stented numerous times and can no longer tolerate a traditional fixed stent. The material is also being used to deliver medicines into organs of the body—for example, a plastic material like a sponge is doped with medicine and inserted into the liver, dispensing medicine at a consistent rate and lasting from six months to three years before dissolving. FIGURE 4 shows a femtosecond laser cut of a bioabsorbable stent.After years of clinical trials, several firms are awaiting approval and already planning for the new innovation to hit the US market, and several have been qualifying use of femtosecond laser equipment to gear up for the precision micromachining required.

Integration into a micromachining tool

The industrial robustness of the femtosecond disk laser needs to be matched to an equivalent system to deliver the day-in, day-out reliability that the medical device industry demands. It is worth noting that the femtosecond laser cannot currently be fiber-delivered and therefore is directed and delivered to the focusing optics by fixed mirrors. So, designing a beam delivery system for a 4-axis tube cutter that can make off-axes cuts while maintaining alignment can be a challenge. The optical path design has to ensure that such key optical tools as the beam expander and fine tuning attenuator are easily accessible as needed for process development. The system design requires full mechanical isolation and in some cases ambient temperature stability to provide a system foundation for process repeatability. Jenoptik teamed with Miyachi America to develop a platform based around Miyachi's Sigma Tube cutter (FIGURE 5).Miyachi is providing the first line of support, including sampling processing, quoting, and building of the work cell, as well as installation, training, service, and warranty. The company uses its in-house femtosecond processing lab to provide a seamless transition from developing the application to the define-design-deliver approach used by the systems engineering group for both standard and custom system fulfillment.

While there is no doubt that mechanical stiffness and isolation are required, this is simply the starting point. Determining how delicate parts and materials will be repeatably positioned or clamped, implementing in-system part inspection and incorporating real-time optical beam diagnostics are several other key pieces of the puzzle.

Optical alignment is important and ensuring that the beam profile and power levels are maintained requires the use of in-line, nonintrusive optical diagnostic tools to provide real-time information. Being in-line and nonintrusive enables data collection during processing that can be time- and date-stamped as part of the manufacturing data.

Bright future for femtosecond disk

The femtosecond disk offers unique process capability with excellent beam quality and high peak powers. To maximize the process capability for production, the laser must be integrated into a system that enables high quality and repeatable processing. The combination of a highly robust femtosecond product that has been on the market for more than eight years with an experienced micro systems provider with in-house parts processing capabilities results in a partnership that can develop ideal production system solutions for high-value medical products.

Geoff Shannon, Ph.D. | Director Strategic Marketing for Precision Manufacturing, Coherent

Geoff Shannon, Ph.D., is Director Strategic Marketing for Precision Manufacturing at Coherent (Santa Clara, CA) and an Editorial Advisor to Industrial Laser Solutions. He previously served as Laser Technology Manager for Miyachi Unitek, specializing in the development of lasers and applications for existing and new markets. Shannon has a BEng in Mechanical Engineering and PhD in Laser Welding Technology from the University of Liverpool. His 20-year career in laser technology has centered around applications research and development and new product development of lasers and systems.

Stephen Hypsh | VP – Business Unit Lasers, North America at Jenoptik

Stephen Hypsh is VP – Business Unit Lasers, North America at Jenoptik (Jupiter, FL).