Wavelength beam combining enables ultra-high brightness at any wavelength

Jay Liebowitz

Ultra-high-brightness direct-diode lasers are a new commercial product that has been creating interest among the world's laser system integrators. I asked Jay Liebowitz from TeraDiode, currently one of only two suppliers, to explain why his company's laser has generated this interest. Readers can get another view by reading an Applications Report by Dr. Silke Pflueger that appears in the January/February issue of Industrial Laser Solutions. —DAB

The two largest applications for high-power industrial lasers are cutting and welding of mild steel, stainless steel, and other metals. These two applications alone form—according to this magazine—a roughly two-billion-dollar market made up of machine tool builders who manufacture cutting equipment for metal fabricators and system integrators who produce automated welding equipment primarily for automotive and other transportation manufacturers. The lasers used in these two applications range in power from 1 to 20kW, but are mostly in the 2–6kW range. They are differentiated not just by power, but also beam quality measured in beam parameter product (BPP), where welding requires BPP values no higher than low tens of millimeters times milliradians (mm-mrad) and cutting demands values 10 times lower in the few mm-mrad. A laser that emits multikilowatts of power and has a BPP value as low as 4 mm-mrad—a combination ideal for high-speed cutting of stainless steel several millimeters thick, for example—is referred to as having ultra-high brightness.

The first generation of ultra-high-brightness industrial lasers, which pioneered laser cutting of metal, were primarily 10-μm-wavelength CO2 lasers, which can be as large and heavy as a pickup truck and have wall plug efficiencies of roughly ten percent. Similar in size are lamp-pumped 1μm solid-state lasers, which have efficiencies of a few percent and beam quality only good enough for welding. Both are also plagued with a variety of maintenance needs. In the last decade, a second generation emerged, based on the commercialization of high-brightness diode lasers. These diodes enabled the pumping of secondary, active media to make higher efficiency, more compact solid-state lasers. Diode-pumped fiber and disk lasers have the size of home appliances and have wall plug efficiencies about three times higher than their first-generation counterparts. Fiber and disk lasers have brightness not just for welding, but also for cutting. Moreover, the maintenance cycles are reduced relative to their predecessors. Recent results in cutting of thick stainless steel suggest that 1μm lasers may make CO2 lasers obsolete.

Direct-diode utility

The use of diode lasers to pump secondary media, of course, begs the question of how to eliminate the "middle man" and use diodes directly. In fact, researchers initiated such investigations immediately upon the invention of the diode laser in the early 1960s. After all, the diode laser is the smallest, most efficient, least expensive, and most reliable laser. At the single-emitter level, the beam quality is extremely high, making fiber-optic telecommunication networks over thousands of miles possible. The challenge is to combine the beams of a vast number of diodes so as to achieve ultra-high brightness while not sacrificing size, efficiency, cost, and reliability.

Inventions in wavelength beam combining (WBC) at the Massachusetts Institute of Technology Lincoln Laboratory during the 2000s, followed by further inventions and commercialization efforts at TeraDiode in this decade, have answered this challenge. WBC is elegant for its simplicity in enabling the scaling of brightness without compromising size, cost, efficiency, or reliability. The founders of TeraDiode come from this group in Lincoln Laboratory and exclusively licensed the intellectual property they developed; TeraDiode has added its own patents in WBC as well.

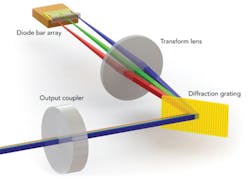

Figure 1 shows how WBC works for a single-diode laser bar; in this case, at a wavelength of 0.97μm. This bar consists of multiple emitters in an array, with spacing between emitters of a few hundred microns. The light from the emitters pass through a transform lens, which focuses the beams onto a dispersive element such as a diffraction grating. On the other side of the grating is an output coupler. Since the overall structure forms a laser, the beams between the grating and the output coupler must be perpendicular to the output coupler so that all the beams emanating from the output coupler are superimposed on each other. Between the diodes and the grating, each emitter passively self-adjusts to a distinctive wavelength, based on its own angle relative to the grating. The result is a narrow spectrum of wavelengths all imaged as though they came from just one emitter.

The value of WBC is the way in which it scales to ultra-high brightness. In fact, the name TeraDiode refers to this scaling capability, where Diode refers to diode laser and Tera is based on WBC's theoretical capability of terawatts/cm2-str. We demonstrated the brightness scaling of WBC by combining two 1kW beams into a 50μm fiber, each generated by an array of 342 emitters in a single plane. Similarly, we preserved nearly diffraction-limited beam quality with over 500W of diode laser power. Each experiment set a world record for direct-diode lasers by at least two orders of magnitude.

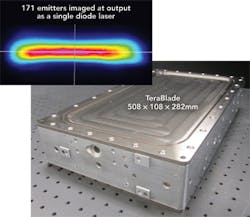

In general, ultra-high-brightness industrial applications do not require diffraction-limited beam quality: in cutting, a too-bright beam results in a kerf that closes in on itself, and in welding, the fusion zone is too thin to have the strength needed for meeting crash safety requirements of the transportation industry. Our basic building block is called the TeraBlade, shown in Figure 2, which is designed for the range of needs in cutting and welding applications. These include brightness, cost, size, efficiency, and reliability, but also scaling, servicing, and maintenance. The WBC architecture is inherently simple, enabling high-volume manufacture at low cost, and is immune to the effects of back reflection, increasing reliability. The main components in the TeraBlade are diode laser bars, which provide the highest economic value for power and reliability and require much less handling than single emitters while having longer lifetimes than diode stacks. In addition, the limited handling of diode bars enables their operation at low currents, extending lifetimes to hundreds of thousands of hours, whereas single emitters, when fiber-coupled, become burdened with costs that require operating them at higher currents, shortening their lifetimes.

Cost savings

WBC technology is also optimal for minimizing cost of ownership. With just a handful of optics inside the TeraBlade, the placement processes are all computer-controlled and highly automated so that the total touch time is well under a person-shift. In addition, all the alignments are free-space so that there are no interfaces that must tolerate hundreds of watts in just a few square microns, eliminating the splice failures that often occur, for example, in fiber lasers. Moreover, the building block architecture of TeraBlade lends itself to easy replacement of blades in the field, satisfying servicing and maintenance requirements.

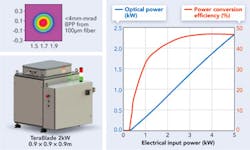

As of the time of writing, our standard TeraBlade uses nine diode laser bars, each 80W and with an electro-optic efficiency of more than 55%, so the TeraBlade itself emits well over 600W and has a power conversion efficiency of 50%. The image in Figure 2 is the free-space output of nine bars, each with 19 emitters, clearly imaged as a single diode laser that has an M2 of fewer than 2.5 in the fast axis and 9 in the slow axis. We integrate four of these 600W modules, using conventional spatial and polarization beam combining techniques, to make the TeraBlade 2kW, which emits over 2,000W with a BPP under 4mm-mrad from a 100μm fiber. Furthermore, we have achieved power conversion efficiency of more than 47%, as shown in Figure 3, and wall plug efficiency just a few percentage points lower. In addition, the TeraBlade 2kW is highly compact, with a volume of under a cubic meter.

This laser is also ideal for scaling brightness economically. As diode laser bar powers go up and their efficiencies rise, the economic value of the TeraBlade platform for brightness proportionately increases. We are engineering new versions that will be at least twice as high in power and more than 10% efficient; the result will be a more economical and efficient 4kW version from the same cubic meter. These innovations will make the gap between WBC and second-generation lasers even more profound, to the point that the shift in the market to ultra-high-brightness direct-diode lasers will accelerate. The shift has begun already, with major machine tool builders and automotive integrators working now with multikilowatt versions.

WBC is disruptive technology for operational efficiency and total cost of ownership, meaning new material processing applications, beyond cutting and welding, will be served based on lower costs per watt and unit brightness. Moreover, WBC works at any wavelength, unlike second-generation lasers that require dopants of rare earth elements, creating the possibility to customize laser wavelength to the material—808nm for aluminum, 450nm for copper, etc.—for maximizing material processing efficiencies and minimizing production costs. Given the value and flexibility of WBC, it is arguable that the third generation of the ultra-high-brightness industrial laser is also the ultimate generation.

Acknowledgement

TeraBlade is a trademark of TeraDiode Inc.

JAY LIEBOWITZ([email protected]) is vice president, sales and marketing at TeraDiode, Inc., Wilmington, MA.