Laser joining of aluminum poised to grow as cars lose weight

Aluminum is a versatile and, in many ways, amazing metal, as it has a very low atomic mass compared to most metals. This low mass, combined with high corrosion resistance and excellent thermal and electrical conductivity, make aluminum a very unique and appealing metal. The great news for manufacturers is that aluminum is easily machined, cast, drawn, and extruded—and there's a lot of it. Aluminum is the third most abundant element in the world, subordinate only to oxygen and silicon, and it's the most abundant metal, making up more than 8 percent of the earth's crust.

Comparison to steel

Comparing aluminum to the other primary manufacturing metal—steel—several key differences become apparent. One major difference is it's resistance to corrosion. Aluminum's affinity to oxygen is attributed to its three valence electrons. Since oxygen can accept two, aluminum oxide (Al2O3) is readily formed. Aluminum oxide is a passive, 1nm-thick surface film that protects the base metal from corrosion and reaction with other elements. If the layer is damaged, it immediately reforms when exposed to oxygen. Steel has no such passive mechanism; in fact, when in the presence of oxygen or water, the iron in steel forms a corrosive oxide known as rust.

The second important difference is the mass. Aluminum's mass is about a third of that of steel, and weight reduction is a key driver for the use of aluminum in many industries, especially the transportation industry. As a general rule, aluminum components can typically be about twice the sheet thickness compared to steel for similar structural performance, providing an overall weight savings of about 33 percent. This bodes well for the automotive industry in particular, which by 2025 must increase fuel economy to a fleet average of 54.5 miles per gallon.

Additional attributes such as aluminum's high thermal conductivity, which is very useful for components such as heat exchangers, and its low electrical resistivity, which makes it a good current conductor, reinforces just how versatile this material is. But all those unique and useful characteristics would mean little if it weren't for the fact that aluminum is also highly manufacturable. It's easily formed, machined and welded, which are all keys to useability.

Welding issues and proven methodologies

With the addition of alloying elements, eight wrought alloy groups emerge, expanding the overall utilization of aluminum into a wide variety of manufacturing applications (Table). However, regardless of the alloy or the application, the question of weldability arises. Luckily, most alloys can be successfully fusion-welded, depending on the alloy filler material that is sometimes required. Joining with lasers can solve some of the problems that plague conventional techniques, such as MIG welding. Compared to MIG welding, laser processing provides higher welding speeds, less heat input, a smaller heat affected zone, much lower distortion and can be welded autogenously in many cases.Aluminum and its alloys do have a few troublesome attributes, however, that may contribute to welding issues if not properly addressed. The wide range of alloy vaporization and solidification temperatures can lead to keyhole instability, porosity, blow holes, loss of mechanical properties and various defects in the weld metallurgy, such as hot cracking. The high rate of hydrogen solubility in molten aluminum can lead to extensive weld porosity and blow holes. The low-viscosity, highly fluid molten aluminum can result in dropping or sagging of the underbead. Finally, aluminum's high reflectivity combined with high thermal conductivity can challenge the coupling of the light energy into the material. As dismal as all of that sounds, the history and success of laser welding of aluminum is quite the opposite. Each and every one of those troublesome characteristics with its related welding issue has a well-defined and production-proven manufacturing solution to overcome each problem. Let's take a brief look at five of the most common issues, the mechanisms and the control measures.

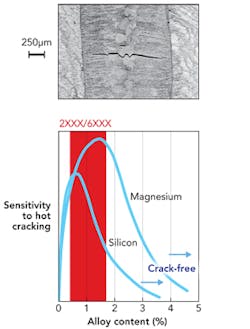

Hot cracking, or weld solidification cracking, is the result of solidification stresses on the microstructure, and is exacerbated by aluminum's high thermal expansion and conductivity. Hot cracking sensitivity can often be avoided by using the appropriate filler wire or inlayed filler foil material to alter the weld chemistry and avoid the crack sensitive peak (Figure 1). For example, typical values of silicon and magnesium for good weldability are >2 to 3 percent and >3 to 4 percent, respectively. The typical range for these alloys in the 2000 and 6000 series aluminum alloys are 0.4 to 1.6 percent, meaning that in most cases these alloys will require filler for crack-free welding.

The solubility of hydrogen in molten aluminum can lead to gross porosity. Hydrogen is actually quite abundant, especially in manufacturing environments, as it is found in water, lubricants, and in the air. The issue here is that hydrogen readily dissolves into molten aluminum, but has virtually no solubility in solid aluminum. Upon solidification, any hydrogen in the molten weld pool is either trapped in the weld as pores or outgasses, causing blow holes. Luckily, the preventative measures are not complicated:

• Keep materials clean and dry, including filler wire or foil

• Avoid temperature differentials (for example, storage to production area) that can cause condensation on the parts or filler material

• Clean weld joints and remove "porous" oxides when needed

• Use a shielding gas

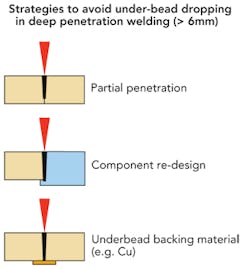

Underbead dropping occurs in through penetration welds in the range of about 6mm and greater, though the exact threshold thickness depends on wavelength, alloy type, power, speed, spot diameter, etc. The simplest way to avoid this effect is to position the weld joint horizontally, but oftentimes this is impractical or impossible. When welding with a vertical weld joint, there are several strategies that can be employed to avoid underbead dropping in deep penetration welding (Figure 2):

• Use a partial penetration weld

• Re-design the component to avoid a through penetration weld condition

• Use an underbead backing material (e.g., copper)

BMW 7 Series doors

Laser welding has been used in the automotive industry for joining of aluminum components such as frames, roofs, doors, deck lids, steering columns, wheel rims, and fuel filters, to name just a few. One noteworthy application is laser edge-fillet welding of the aluminum doors on the BMW 7 Series luxury sedans (Figure 3). Aluminum was the material of choice for BMW engineers; not only for the light weighting benefits, but also because of the critical experience they could gain in laser welding aluminum for future implementation on higher volume vehicles. Though the selected alloy (Al 5083) is autogenously weldable, manufacturing engineers chose to use the edge-fillet joint design and laser weld with filler wire to keep flange width to a bare minimum. This allowed them to maximize the cross-section (Figure 4) and thereby increase the section modulus and moment of inertia with minimum material utilization. Laser-welded doors have 1.7 times greater section modulus and a factor-of-2.3-greater moment of inertia compared to resistance-spot-welded doors, yielding a significant improvement in both strength and stiffness. The four aluminum doors per vehicle incorporate over 15 m of laser-welded seam and are roughly 30 percent lighter than their steel counterparts. An additional benefit of the tight and more continuous laser welding seam is the elimination of adhesive, further reducing both weight and cost.The weight-to-strength ratio and corrosion resistance of aluminum are two of the many reasons why manufacturers have looked to aluminum as a desirable metal for their applications. While most aluminum alloys are fusion-weldable—either with or without fille—-there are a few well known and understood welding issues that are readily overcome by production-proven methodologies. To punctuate that reality, numerous components comprised of aluminum and aluminum alloys from a variety of industries have been laser-welded in production since the 1990s. The BMW 7 Series luxury sedan is a great example where a vision for the future, laser processing, strength, light weighting, and cost all come together to create an elegant solution. With the fuel economy mandates in automotive, light weighting is inescapable. Aluminum is certain to be a significant part of that endeavor and because of its advantages and capabilities, laser joining is just as certain.

About the Author

David Havrilla

Manager of Products and Applications, TRUMPF Laser Technology Center

David Havrilla is the manager of products and applications at the TRUMPF Laser Technology Center (Plymouth, MI).