Separating thin glass

Heinz-Georg Geissler

Innovative laser cutting technology has become the standard in cutting glass in several industries

Because of the current quality requirements for glass products, processing techniques must become more precise, smaller, and purer, apart from considering the different material properties. In growing and demanding markets such as electronics, innovative technologies for glass cutting are highly desired.

Conventional separation methods for glass, using hard metal or diamond tools, have been widely used for many applications, with the cutting process divided into two steps. First the glass is scribed by a diamond tip or a carbide cutting wheel, producing a crack line on the glass surface; then, in a second step, the glass is mechanically broken along the crack line.

However, this method of scribing and breaking has disadvantages. The removal of material causes chips, fragments, and microcracks, reducing the edge strength and making a subsequent cleaning procedure necessary. The induced deep crack is often not perpendicular to the glass surface because of the mechanical introduction of force, with a nonvertical cutting line resulting. And the yield loss due to the mechanical impact of force on thin glass is a factor.

These disadvantages can be reduced by using tension-free glass and by extensive optimization of the tools and installations for breaking. However, it is not possible to avoid the systematic contradiction between a vertical cutting line and the prevention of edge chips and fragments. The development of laser technology has led to a solution for these quality issues.

Laser scribing and breaking

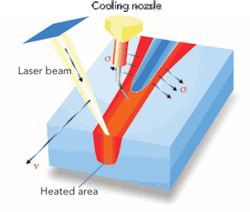

Unlike the mechanical cutting tool, the energy in a laser beam cuts the glass in a noncontact manner. This energy heats the workpiece, locally limited, to a defined temperature. The quick heating of the workpiece followed by rapid cooling produces tensions within the glass causing a vertical, fragment-free or chip-free crack along the tension-induced fissure line (see Fig. 1). As the crack is only thermally induced, not mechanically, there are no edge chips and/or microcracks. Therefore, the strength of the laser-cut edge compared to the conventionally scratched and broken edge is greater. The need for a finishing treatment will be reduced or will become obsolete. Moreover, the formation of broken glass fragments will be completely avoided.

For laser scribing, the glass is scratched up to a depth of approximately 100 μm (10% of the glass thickness) by a heating and subsequent cooling procedure (see Fig. 2). The glass can then be broken due to the well-directed weakening. Because this technique does not produce any glass fragments, a weakening of the edge strength is prevented, and the subsequent steps of polishing and washing are not necessary. Furthermore, the glass is three times as break-proof as a conventionally separated glass panel.

For glass from 50 µm to 1 mm thick, even a complete cut in one step is possible (see Fig. 3). The breaking step becomes obsolete, as well as all subsequent steps such as washing or polishing.

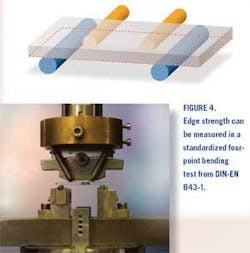

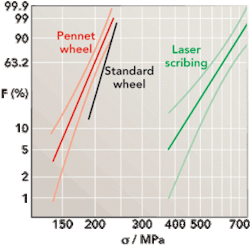

The edge strength can be measured in a standardized four-point bending test from DIN-EN 843-1. A piece of glass is fixed on two rollers (see Fig 4). On the top side, two additional rollers are used to induce a defined bending force, and the force under which the glass breaks is measured. This test is repeated approximately 100 times to get a proper statistically reliable value of the probability of breaking (see Fig. 5).

In most cases laser scribing and breaking is the choice for processing in mass production. The advantages are high process speed, high accuracy, and easy parameters. However, in situations of cutting a few lines and sufficient process time, full body cutting is an attractive method because of its dry cooling method and no additional breaking step. In both cases, the result is an edge of highest quality. So there is the potential of saving time and improving quality simultaneously if cutting glass by laser.

Laser cutting in production

It is not easy to transfer a new and sophisticated technology into mass-production lines for high-technology products. From the customer’s point of view, it must be a well proven, automated, reliable, and economically sensible solution before implementation into mass production. Practically, the use of innovative technologies works only under two circumstances: with the establishment of new products that count on new production methods to enable innovative features or to reduce production costs by saving processing steps, or if existing production is under such high financial pressure that dramatic production method changes are going to be considered.

In the flat-panel-display industry, the implementation of laser cutting took about five years to find its place in production lines, after passing several thousand hours of use in several prototype lines. Now it is routinely considered for the production of new products that have a danger of breakage or in the electronics industry for any mobile devices containing glass or products using thin glass that are seen as a potential weak part, such as sensors, touch panels, or cover glass.

Processes occurring in a cleanroom, such as in the biomedical industry, are opportunities because these are extremely sensitive to particles that might result from conventional cutting or grinding steps. Examples are substrates coated with DNA-codes (bio slides) or substances for grocery tests cut in pieces by a laser. The next potentially large industries to take advantage of laser cutting are the solar industry and the automotive industry.

Laser cutting technology for glass will develop as it did in the metal industry years ago; it will be established for a wide range of products by replacing the traditional methods. However, traditional methods of processing glass will, in the future, remain an essential part of production as the majority of glass products do not have requirements for high edge quality.

Laser shape cutting is an innovation that may find its place in the electronics, automotive, or architectural industries. Beside laser cutting of glass there is also potential for further laser-processing methods on glass, such as drilling, chamfering, and coating removal, all in the development/sampling stage. These processes require different laser types, such as green lasers.

The established CO2 laser cutting technology is used on other brittle materials such as ceramics used as wafer material in the electronics industry. Other new materials used in the semiconductor industry are possible candidates and are waiting to be tested and put into production.

Heinz-Georg Geissler ([email protected]) is vice president for sales/marketing at MDI SCHOTT Advanced Processing in Mainz, Germany.