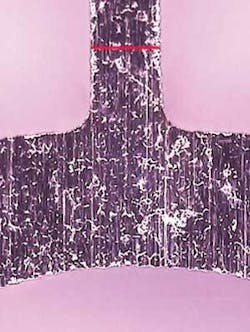

FIGURE 1. Comparison of conventional (left) and Laser MicroJet (right) cutting quality of 316 L stainless steel.

Laser combines with water jet to revolutionize the manufacture of medical devices

Keith Stay and Bernold Richerzhagen

Today, surgical procedures increasingly use precision instruments for delicate and often intricate operations. These devices require particularly high manufacturing standards, such as clean surfaces, smooth edges, no thermal or mechanical damage, and high cutting accuracy. Until now the manufacturers of these devices have relied on either conventional laser or etching processes for production. Now the water-jet-guided laser also is being applied for the manufacture of high-quality devices.

This technology (Laser MicroJet) is based on focusing a laser beam into a nozzle while passing it through a pressurized water chamber. The laser beam propagates through the water jet and is emitted from the nozzle by means of total internal reflection taking place at the water-air interface, in a manner similar to conventional glass-fiber transmission.

Either flashlamp-pumped infrared (IR) lasers or multimode diode-pumped Q-switched lasers are used, operating at 1064 nm (IR), 532 nm (green), or 355 nm (ultraviolet). The laser wavelength can be chosen freely as long as it fits within the water-transmission spectrum. Pulsed (duration 100ns to 100μs) laser power is used, so that during the interval between pulses the water jet efficiently cools the workpiece in the area where ablation has taken place. To avoid either absorption or scattering of the laser beam, pure deionized and filtered water is used, pressurized between 100 and 500 bar, depending on the nozzle diameter and required cutting length. Mechanical forces applied by the water jet to the target material are negligible, typically ranging from 0.1 to 0.5N.

Comparison of benefits

In conventional laser cutting, the laser is focused on the piece to be cut, with the beam forming a conical shape before and after the focal point, resulting in a short working distance and requiring precise focus control. Using a water jet to guide the laser beam, the working distance corresponds to the stable portion of the jet. This is usually several centimeters, depending on nozzle size, and is about 100 times longer than with a focused laser. After leaving the nozzle, the MicroJet is perfectly cylindrical and constant, resulting in excellent kerf parallelism. It can achieve a variable depth of cut, depending on the laser pulsewidth/frequency programming.

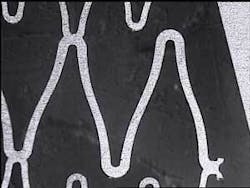

FIGURE 4. Close-up of stainless-steel tubular stent cut with the Laser MicroJet from 1.5mm diameter tube.

Overheating is one of the main problems of laser-based cutting, because the cut is achieved by heat absorption. However, with the laser/water jet, the water prevents thermal damage within the material by cooling the laser processed area and its surroundings between laser pulses. The heat-affected zone is so greatly reduced that the usual negative effects (such as microcracks, oxidation, or low fracture strength) are practically eliminated (see Figure 1).

A second issue with conventional laser technologies is the removal, using an assist gas, of molten material generated by the ablation process. However, this technique is inefficient because of the low density and compressibility of the gas. Using a water jet, the ablated material is efficiently removed, as the kinetic energy of the water passing through the kerf is high. The water jet instantly cools the remaining particles and flushes them away from the cutting area, at the same time forming a thin water film on the surface of the piece, eliminating the requirement for protective coatings to prevent deposition and providing savings on material and manufacturing costs.

Medical device applications

Because it generates little or no thermal damage and contamination, the water-jet-guided laser offers several advantages to medical device manufacturers. The process has so far been applied to the manufacture of stents, blades, scalpels, needles, tubes, and piezoceramic substrates for ultrasound devices.

FIGURE 6. Edge of a silicon blade for ophthalmic surgery (contour), directly after cutting.

Stents, both as expandable wire mesh or perforated tubes, find many uses in minimally invasive surgery and are used to counteract a localized constriction in a bodily organ, such as an artery that has recently been cleared with angioplasty. The stent is first collapsed to a small diameter and put over a balloon catheter. It is then moved into the affected area, where the balloon is inflated, expanding the stent, which locks in place forcing the artery to remain open. The stent is left permanently in place, improving blood flow to the heart muscle and relieving symptoms of stenosis (chest pain). Because the stent will remain inside the human body and is crucial to the patient’s long-term health, the finish is paramount, requiring a high level of quality control during fabrication-clean smooth surfaces with no attached dross or burrs.

The devices require the cutting out of intricate patterns in the metal sheet or tube to obtain struts, the shape of which together with the type of material employed determine its expansion characteristics. The main materials used are flat or tubular stainless steel, titanium, or Nitinol (NiTi) of varying thickness or diameter. Of these three materials, 316 L stainless steel, which is nonferrous, is the most commonly used. For flat sheets, which are later bent to form a tube and welded, the material thickness can vary between 100 and 200µm. For tubular stents, the diameters typically vary from 1 to 5mm and the tube wall thickness from 30 to 600µm.

Conventional Nd:YAG laser cutting characteristically leaves an oxide layer on the surface of the stent and remelt on the sides of the struts due to diffusion of the laser beam. These unwanted artifacts must then be removed, typically with a closely controlled micro-blasting process, to avoid weakening the strut joints, which could lead to premature device failure. Besides these additional processing steps, other factors such as cutting speed and the degree of automation required contribute to a limited throughput in stent production.

In comparison, the Laser MicroJet provides excellent and fast cutting quality (parallelism and smoothness) and no thermal damage. Stent materials exhibit excellent absorption properties at IR wavelengths, and so efficient machining with IR lasers is possible. Using a short-pulse IR laser within the water jet, a clean, remelt-free cut is achieved, and the continuous water jet immediately cools the material. The results are a very narrow burr-free cut with parallel kerfs, little or no thermal penetration, and no oxidation. As no remelt is created during the cutting, microblasting can be significantly reduced or even eliminated. The laser/microjet process increases the quality of the manufactured item and removes the danger of stent failure due to weakened struts.

The Laser MicroJet technology is highly suited to the manufacture of blades, scalpels, and needles. The blades are usually made from steel, carbon steel, tungsten carbide, ceramics, or diamond. Tubes include an array of devices such as cannulae, or endoscopes, with the wall thickness varying from 30 to 600µm. The tubes are conventionally made of steel, stainless steel, titanium, or Nitinol. The main manufacturing tasks are cutting out of slots, cutting of complex shapes, edging, drilling, and grinding.

An example of such an application is the cutting of a silicon ophthalmic blade from 350-μm-thick material. The laser system creates the blade contour and fixation holes, while etching produces the cutting edge. Using an Nd:YAG green laser (wavelength 532nm, average power 30W), high cutting rates of 15mm/s are practical. The edge quality of the contour is shown in Figure 6.

In the medical field, piezoelectric (PZT) materials, which are also ceramics, are used for ultrasound devices. Although it is a brittle material, the PZT does not suffer from thermal or mechanical damage when being processed by the Laser MicroJet. Any shape can be produced, and contamination is negligible (see Figure 7).

The water-jet-guided laser is fundamentally different from conventional lasers, offering many advantages to the medical-device industry, such as efficient ablated material removal, reduced particle contamination, minimal HAZ, high-speed cutting, and negligible mechanical constraints on the workpiece. It is well suited to cutting stainless steel, shape-memory alloys, silicon, and PZT materials to any required shape and in very small dimensions.

Keith Stay and Bernold Richerzhagen are with Synova SA (www.synova.ch), Ecublens, Switzerland.