Solution combines state-of-the-art cleaning with process monitoring and in-line process control

EDWIN BÜCHTER

Laser cleaning started in Germany in the late 1990s and the technology has since established itself in industry. For example, in the U.S., several hundreds of installations in automotive, aeronautics, and general industry have proven the potential of laser cleaning.

The laser-based surface pretreatment of industrial components and surfaces is often an economical alternative to conventional component cleaning. In addition to its low energy consumption, the media-free process does not require any chemicals or abrasives, which is why cleaning with light is particularly sustainable and environmentally friendly.

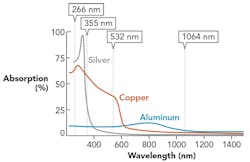

To avoid damaging the surface of the component, industrial cleaning lasers with short pulses are used. Depending on the intensity, pulse duration, and wavelength, different effects and surface properties can be adjusted. The spectrum ranges from gentle cleaning to selective surface structuring. The effect of laser radiation depends on the absorption of the processed material (FIGURE 1).

FIGURE 1. The absorption spectrum of different metals is shown. (Courtesy: Laser Zentrum Hannover [LZH])

Metals have a high reflectivity for the typical solid-state wavelength of 1064 nm, while impurities and oxides on the surface will absorb the laser radiation better. Moderate beam intensities can therefore be used to remove contamination from the surface without damaging the metal underneath. When cleaning with light, organic and acidic oxide contaminations are efficiently blown off from the surface of metallic components.

By intensifying the laser parameters, metallic materials in the uppermost boundary layer (typically up to 5 µm) can be modified to create structures or roughness. One example is to improve the corrosion behavior of light metals and to increase the surface area by roughening.

Laser beam cleaning offers high precision and reproducibility, therefore saving enormous costs in industrial series production. The investment in current laser technology is often many times cheaper than that in, for example, wet chemical alternatives. In addition, the running costs of highly efficient laser machines are usually significantly lower because of their low energy consumption (a few kilowatt hours) and moderate maintenance requirements. Significant savings in component unit costs can thus be achieved, especially with large part quantities and fully automatic processes.

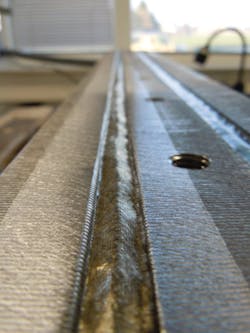

The flexibility that laser cleaning offers makes it suitable for various industrial applications, including pretreatment of joints for bonding and welding; accurate contour removal of coating to, for example, provide electrical contact; paint stripping for adhesive pretreatment; and post-treatment of welding seams and descaling of steels prior to varnishing/cathodic dip coating (FIGURE 2).

FIGURE 2. Precise decoating of metallic surfaces is demonstrated.

Standard optics and special versions

Laser beam cleaning optics are available for a wide range of applications. Optics are connected to the powerful base units by means of fiber-optic cables, have an application-oriented design, and have been developed, in part, for complex component geometries.

For example, the optics of the Share Motion series can clean a vertical tongue-and-groove geometry (FIGURE 3). The optics only need to be moved along the groove by means of a linear movement. Because of the multiple beam deflection, it is possible to achieve an efficient adhesive pre-treatment with a simple movement and almost no nonproductive times at an optimum beam angle. Depending on the complexity of the path contour, the efficiency increase in process quality and speed that can be achieved compared to conventional robot-guided motion is up to 76%.

FIGURE 3. The Share Motion special optics for the machining of slot spring geometry are shown.

Post-weld cleaning

CleanLASER offers laser-safe cleaning machines that can be integrated directly into running production because of their modular and compact design, which can be adapted to individual customer requirements in terms of laser power, workspace, and loading. The mobile lightCASE compact laser system has uses, for example, in nondestructive testing and weld seam stripping in aviation or shipbuilding.

The lightCASE system’s steel housing with carrying handle is as compact as a beverage crate. Its 100 W laser is operated via an intuitive touchpad panel. The system has already proven its worth in very cramped operating conditions—for example, in the case of partial weld seam stripping for nondestructive testing in the interior of a submarine (FIGURE 4).

FIGURE 4. The lightCASE compact cleaning lasers have utility in aviation and shipbuilding.

Welding seams can be specifically re-treated and the surfaces removed from deposits. The laser cleaning process, which is carried out at short intervals directly after the welding process, enables dirt, oxide, silicate, and slag layers to be removed quickly and cost-effectively. After the melt has solidified, oxides and silicates are removed from the surface with the CleanLASER.

In the middle of the weld seam, a large area of silicates is formed, which are mainly found as islands. These lie on the relatively smooth surface and can be removed very well with the laser. In the edge area of the weld seam (the seam root), the silicates can be partially well-bonded and shaded by the throw-up, and can therefore be removed more difficultly. The laser beam is directed to the surface at an incidence angle <90° to remove these edge silicates. In this way, these areas can also be removed without leaving residues, even at high laser intensity (FIGURE 5). By means of an additional after-cleaning with the laser, tarnishing colors that occur at high intensities can be removed again.

FIGURE 5. Residue-free laser after-treatment of weld seams.

The laser process replaces cost-intensive and nonreproducible brushing and blasting processes, especially for aluminum and steel welds. The processing speed is up to 10 m/min.

Process monitoring

The interaction of the laser beam with the surface not only leads to a modification of the surface, but also to characteristic process lights during processing. During the evaporation of the soiling and the metal oxide layer close to the surface, a plasma is generated that, depending on the radiation intensity, shines brightly for simple detection, therefore enabling effective process control.

Plasma intensity measurement is a special method that can only be used in the laser process and combines numerous disturbance variables in a collective signal. Clean-Lasersysteme (Herzogenrath, Germany) has developed a plasma sensor that records the brightness curve during laser processing and compares the measured curve with reference curves or fixed limit values to determine a measure of process capability. Flexibly configurable, graphically based software supports the setup of the system with automatic measurement and reference functions. Therefore, minimal intensity fluctuations can be detected in the production process and limits for quality characterization, and 100% in-line control can be defined and used according to different criteria. The component itself neither needs to be touched nor removed from the process for the measurement.

The final goal for all the company’s laser systems is to minimize costs and reduce the burden on the environment. ✺

EDWIN BÜCHTER([email protected]) is managing partner of Clean-Lasersysteme (cleanLASER), Herzogenrath, Germany; www.cleanlaser.de.