Fiber laser technology improves metal cutting

The sheet metal cutting market is dominated by fiber lasers because of their unmatched combination of productivity, precision, and cost-effectiveness. Fiber lasers in the 2–6 kW range have become workhorses for many fabrication shops, offering faster and more precise cutting of thin metal than legacy cutting technologies, such as carbon dioxide (CO2) lasers and plasma torches. Many fiber laser systems are, however, designed for cutting a limited range of metal thicknesses. Specifically, a small, tightly focused laser beam provides the fastest cutting speeds for thin gauges, but for thicker plate this small beam has significant limitations in edge quality and maximum thickness. Alternatively, a larger beam can improve the edge quality for thick plate because of the wider kerf, but with a substantial speed penalty for cutting thin sheet.

Large fabrication shops may purchase multiple fiber laser tools, where each tool is dedicated to cutting a particular thickness range: a small-beam system for light gauges and a larger-beam system for thicker plate. Smaller fabrication shops that rely on one tool to cut the full range of metals will have lower productivity if they are limited to one spot size, especially if they have a diverse job mix. These shops typically change the focusing lens in the cutting head to better optimize the laser spot size for a given job. Each change of the lens causes lost productivity when the laser is not cutting, and it risks contamination of the lens and the cutting head, which can result in catastrophic failure and significant repair costs and downtime.

The ability to automatically tune the laser spot size would greatly extend the applicability, productivity, and process window of fiber lasers. Most existing approaches entail motorized free-space optics. Examples include zoom cutting heads, fiber-to-fiber or free-space-to-fiber couplers that vary the launch conditions into the fiber, or fiber-to-fiber switches with 2–4 outputs coupled to independent process fibers. Such free-space optical approaches entail significant cost and complexity and can degrade tool performance and reliability. They are sensitive to misalignment, contamination, and environmental conditions (temperature, vibration), introduce power dependence (thermal lensing) and optical loss, and/or have slow switching speed. Zoom cutting heads, which incorporate a motorized lens within the head, are larger and heavier than standard cutting heads, resulting in reduced acceleration and imposing additional design requirements on the gantry and motors. Tool designers resorting to these approaches are required to pass along the cost, performance, and reliability burden to their customers (the end users).

The lack of tunability of the spot size from existing laser sources thus forces tool integrators and fabrication shops to choose between flexibility in the job mix and tool performance and reliability. This compromise drives up costs and leaves productivity on the table.

Fiber laser breakthrough

nLIGHT has developed a novel, all-fiber technology (Corona) that enables rapid tuning of the fiber laser spot size directly from the feeding fiber over a range of more than 3X without any of the drawbacks of free-space approaches. In addition, Corona fiber lasers provide beam shapes that have shown improved cutting quality for various metals, including flat-top and annular (donut) beams. Corona fiber lasers at the 4 kW power level have delivered greatly improved performance over conventional fiber lasers for sheet metal cutting of mild steel, stainless steel, aluminum, and copper for thicknesses up to 1 in., enabling the development of universal tools for optimized cutting of a wide range of metal thicknesses.

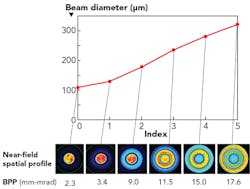

The Corona fiber laser output beam is continuously tunable between ~100 µm and ~300 µm. To facilitate process optimization, a fixed number of settings (Index values) are provided. FIGURE 1 shows the output beam diameters, beam-parameter product (BPP) values, and beam shapes of a Corona fiber laser with six Index settings.

As is evident in the beam images shown in FIGURE 1, the feeding fiber is divided into zones that guide the laser beam. Many different Corona fiber designs are possible to address a wide range of applications. In the design shown in FIGURE 1, the feeding fiber consists of a 100 µm central core surrounded by two annular guiding regions with diameters of 200 and 300 µm. The beam diameter and beam shape are tuned by varying the partitioning of the laser power among these three guiding regions. The critical and unprecedented feature of Corona is that this tuning of the beam shape is accomplished all within fiber and with no free-space optics, thereby maintaining all of the performance, stability, efficiency, and reliability advantages of fiber lasers. The full laser power is available at each Index setting.

An additional advantage of Corona is that beam tuning is very rapid, with a transition time from the smallest to the largest diameter of <30 ms. The fiber laser continues to operate at full power during an Index change, with no need to turn off (or blank) the laser while changing the beam shape. Corona’s rapid tuning enables use of the optimum beam characteristics for each step of the cutting process, not just for cutting of different materials or thicknesses. For example, different Index settings can be used during the piercing sequence vs. cutting or during straight cutting vs. cornering.

Metal cutting performance

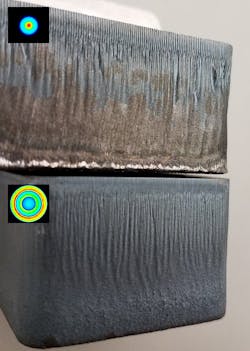

The general metal cutting market, including laser cutting, is dominated by thick mild steel (MS) plate. The Corona fiber laser offers unique benefits in edge quality and maximum thickness for thick MS cutting compared to other laser systems. FIGURE 2 shows photographs of MS cut with both a standard 4 kW fiber laser with a 100 µm feeding fiber and a 4 kW Corona fiber laser. A fixed-optic cutting head with 1.5x magnification was used for all tests, and the assist gas was oxygen. The optimum Corona beam shape is shown for each case, and the cutting speed and measured surface roughness are presented in the graph.Key observations are:

- For the thinnest sample (0.25 in.), the optimum Corona beam diameter is 100 µm. The cutting speed and edge quality are similar for the two fiber lasers, as expected because the lasers have similar spot size and BPP at this Corona setting.

- For thicker samples, the Corona fiber laser provides significantly better edge quality, with the roughness reduced by up to 3X. The optimum Corona beam diameter is >100 µm for these samples.

- The maximum thickness that provides consistent drop performance is 0.75 in. for the standard fiber laser. The Corona fiber laser substantially extends the range to 1 in. thickness with outstanding edge quality.

- The roughness of parts cut with the Corona fiber laser has a much lower dependence on thickness than parts cut with the standard fiber laser. The measured roughness of 1 in. MS cut with Corona is even less than that of 0.5 in. MS cut with the standard fiber laser. This high edge quality reduces or eliminates the need for costly and time-consuming post-processing steps.

- The cutting speed of the Corona fiber laser is the same or slightly faster (~5%) than that of the standard fiber laser.

It is important to note that the edge-quality and thickness-range benefits provided by the Corona fiber laser do not entail a speed penalty (FIGURE 2), and the cutting tool employed a standard, fixed-optics cutting head. This no-compromises performance is unattainable with any other technology and is derived from the unique, all-fiber design of Corona.

We have also explored nitrogen-assisted cutting of mild steel, stainless steel, aluminum, and copper using a 4 kW Corona fiber laser. In most cases, the smallest Index setting provides the best performance, with cutting speeds and edge qualities similar to a standard 4 kW fiber laser. This result is expected because Index 0 provides the highest power density on the workpiece. For nitrogen cutting of some of the thicker materials, however, higher Index settings provide better edge quality for some applications with a penalty in speed because of the lower power density. In these cases, the optimum Index setting is application-specific, and Corona allows the tool integrator or end user to tailor the edge characteristics to the application.

Reliability

All nLIGHT fiber lasers include robust, hardware-based protection against back-reflections from the workpiece, enabling uninterrupted processing of highly reflective materials. Corona retains this high back-reflection tolerance, and Corona fiber lasers have been used for cutting and welding of copper and other reflective materials.

We have characterized the Corona lifetime in accelerated life tests. A Corona fiber laser was cycled through its Index settings with a 100 ms dwell at each setting, and the beam diameter was measured periodically to look for drift or degradation of the performance. Over 13.4 million Index changes, the beam diameter for all Index settings stayed within 4%, with no systematic changes or drift. Corona fiber lasers thus offer the long lifetime and maintenance-free operation characteristic of high-performance fiber lasers.

The Corona fiber laser represents a major advance over standard fiber lasers and over previous technologies for providing tunable beam quality, with advantages that include:

Corona’s tunable beam quality now enables development of universal tools for optimized cutting of a wide range of metals and thicknesses. The job shop or factory is no longer forced into a choice of compromised performance, procurement of multiple tools, and/or use of complex, expensive, and fragile free-space optical technologies.

ACKNOWLEDGEMENTS

nLIGHT is a registered trademark of nLIGHT, and Corona is a trademark of nLIGHT.

About the Author

Brian Victor

Director of Industrial Applications, nLIGHT

Brian Victor is Director of Industrial Applications at nLIGHT (Vancouver, WA).

Dahv Kliner

Vice President of Fiber Laser Technology, nLIGHT

Dahv Kliner is vice president of fiber laser technology at nLIGHT (Vancouver, WA).