Project to develop improved optics for laser surface treatment

AACHEN, GERMANY – Most laser processes for surface finishing can be described as high precision and quality, but too slow. Recognizing this, the Fraunhofer Institute for Laser Technology (ILT; Aachen, Germany), together with nine international partners, will be developing two new optics to quickly adapt laser beam shape to constantly changing laser surface treatment situations.

The research project, dubbed ultraSURFACE, involves companies and institutes from Germany, Belgium, The Netherlands, Israel, and Switzerland researching and developing what they call ultra-dynamic optical systems for high-throughput laser surface processing. Two new laser optics for the near-infrared (near-IR) range they are developing will reduce the processing time of surfaces ideally to one-tenth and cut costs by half.

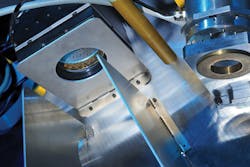

FIGURE 1. A piezoelectric deformable mirror (PDM) developed in the EU project ultraSURFACE is shown. (Copyright: Fraunhofer ILT, Aachen, Germany)

One of the optics is specifically designed for polishing and processing thin layers with lasers and a continuously adjustable piezoelectric deformable mirror (PDM; FIGURE 1). This ensures that the laser beam adapts to the processing situation with switching intervals of <5 ms (FIGURE 2). The laser beam is reshaped depending on the angle of incidence so that its projection on the workpiece surface always has the same shape and the intensity remains constant. This manipulation is important because only if the three-dimensional beam is continuously adapted at high processing speeds and hits the surface with constant intensity will the result of the laser processing always be the same, even with complex-shaped components and constantly changing angles of incidence. On the other hand, if the laser beam projection deforms on slanted surfaces, the quality of the processed 3D surface also deteriorates.For laser structuring, a second optic was developed that allows four beams to be used in parallel, instead of the usual single beam, to increase processing speed and productivity. With a diffractive optical element (DOE), the laser beam is split into a square beam of four partial beams. In the ultraSURFACE project, a special system has been developed with which each individual partial beam can be adjusted in its position within milliseconds so that there is always a square beam for processing.

Two compact optical modules are currently being developed. The ultraSURFACE team will test their potential in a new laser system in various applications until the end of 2018. A Swiss company is building an industrial-grade machine that can be used to polish, structure, and coat flexibly, cost-effectively, and quickly, thanks to the quickly interchangeable optical modules. Using the new optics and the new machine, processing will be 10X faster so that laser-based surface finishing will offer a cost-effective alternative to conventional surface finishing for many companies from various industries.

For more information, please visit www.ultrasurface.eu.