Q-switched CO2 lasers deliver power

Stephen Lee

Recent work takes advantage of the high peak power potential and high beam quality available from this new class of gaseous lasers

The Q-factor is typically switched by one of two common methods: A rotating cavity mirror or electro-optical (EO) modulation. Rotating mirror techniques are slow and require moving parts and thus are less attractive solutions in a solid-state, high-tech world.

EO modulators are very fast response solid-state shutters that prevent feedback and create loss in the cavity through a change in the state of polarization of the light circulating in the cavity, effectively preventing gain saturation, enabling small-signal gain build-up.

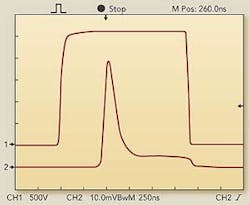

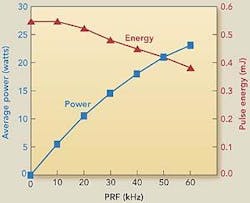

Coherent's GEM Series Q-switched lasers have demonstrated 150 ns full-width half-maximum (FWHM) pulses at 100 kHz pulse repetition frequency (PRF) repetition rates with pulse energies of 0.5 mJ. This results in high peak powers in excess of 3 kW. Figure 3 illustrates typical power-repetition rate performance.

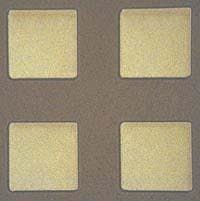

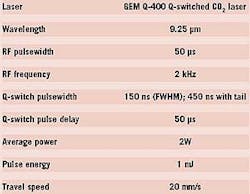

ApplicationsIn general, CO2 laser drilling accounts for approximately 80 percent of the laser microvia market.2 Therefore this is the first significant commercial application for Q-switched CO2 lasers. Other commercial applications include skiving polyimide from flex circuitry and marking glass.The laser was used to skive polyimide from copper on a flex circuit board. A galvanometer was used to raster scan a focused laser beam, with a calculated spot size of 50 micron, located 60 mm below the scanner. A number of tests were conducted using a variety of scan speeds, pulse duration times, PRFs and scan line spacing to determine the optimum operating parameters, which are listed in the table.

No charring was observed and the polyimide was successfully removed from large areas, especially in places where copper leads and circuit patterns were covered. Moreover, no additional cleaning of the polyimide was required from the flex circuitry. Non-tenacious debris created was removed using conventional cleaning techniques, such as permanganate de-smearing.

Material processing of polyimide, silicon and glass at nine microns, coupled with the ability to deliver large amounts of energy in short pulses through Q-switching, will enable faster and more efficient flex circuit machining, micro-machining of plastics, microvia formation in printed circuit boards, silicone tube cutting and glass marking.

These capabilities are now available for the first time in a production-grade, robust Q-switched CO2 laser designed specifically for commercial materials processing applications.ReferencesStephen Lee, "CO2 processing at 9 microns," Industrial Laser Solutions, March 2002.