By Gilbert J. Haas

The adaptive optic is an adjustable optical device. It's mirror surface, or curvature, is deformed via high–speed piezoelectric actuator offering a standard performance of 25 Hz. The devices from Diehl Munitionssysteme GmbH (Nuremberg, Germany) are available with a 40–mm or 60–mm clear aperture. The 40–mm design can handle laser powers of 3.5 kW while the 60–mm design can handle up to 6 kW. The mirror surface can be changed ±20 microns from concave to convex with several custom versions available. An internal wire strain gauge provides a closed–loop position control to provide consistent and repeatable mirror deflections with a resolution down to 1 micron.

Applications

The implementation of adaptive optics can offer many new and improved laser–processing solutions. Brief descriptions of some applications follow.

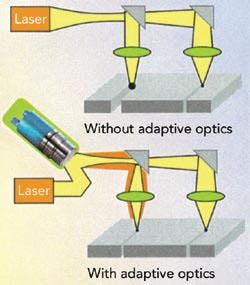

Focus size–Flying–optic laser beam delivery systems consist of moving mirrors and lenses that transmit the laser beam from the laser source to the laser process head as it travels back and forth over a workpiece. As the lenses and mirrors in the beam delivery system change their position, the laser beam path length also changes, affecting the laser beam divergence. The result is variations in the focus spot size and focus position.

To correct this effect, an adaptive optic is added to the beam path near the laser source to control the beam divergence or beam diameter falling on the focusing optic (Figure 1). The adaptive optic solution eliminates the alternative use of moving telescopes, multi–mirror articulated arm systems and tromboning optical systems. In addition, adaptive optics used in conjunction with diffractive optics can provide an on–line, closed–loop system to monitor and compensate for beam divergence.

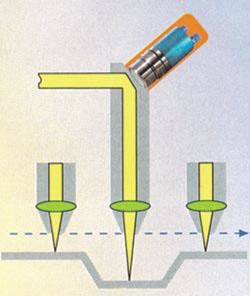

Focus position–Thick section laser cutting techniques such as piercing and cutting require the ability to shift the focus. An adaptive optic added near the focusing lens will shift the laser focus on demand (see Figure 2). For example, an adaptive optic placed in this location will shift the focal point 10 mm at a speed up to 25 Hz when used with a 7.5–in. focus lens. Adap tive optics provide a high–speed low–mass fo cus shift solution while eliminating the alternative need to mechanically move the focus lens.

Figure 2. Focus position control.

3D laser processing–3D laser processing de picts a process where the path of the nozzle is kept constant while the focus is varied to track the workpiece. The performance of 3D laser applications is limited to the dynamic behavior and ability of the handling system to quickly respond to focus position corrections and complex workpiece structures without collisions. The combination of adaptive optics and a sensor system (capacitive, plasma diagnostics, etc.) offers new technologies in 3D processing and laser beam welding. The result is simplified programming, which provides a high–speed, low–mass, focus correction solution of tracking complex structures.

Remote laser processing–Remote laser processing incorporates a high–speed, two–axis galvo system to position the laser focus in the X and Y axes. The integration of adaptive optics into this system can now be used to provide the required high–speed focus position control. The result offers extraordinary possibilities in high–speed laser processing. In addition, a fast interaction of the laser parameters and process control becomes possible providing a powerful laser processing tool. Remote laser processing applications include laser scribing, laser stereolithography, laser cladding/sintering and remote laser welding.

Laser process control–Laser process control can be accomplished through the use of adaptive optics and intelligent process sensor systems. A simple solution for focal size control can now be implemented to control energy density during welding processes when integrated with on–line sensors. In addition, adaptive optics can be used to compensate for degrading laser power due to output coupler aging.

Dual–spot welding–Dual–spot laser welding applications provide a preheat and weld condition onto the workpiece. Adaptive optics can be used to simulate a dual–spot application when incorporated near the focusing lens to shift the laser focus. Adaptive optics can easily be programmed to provide high–speed shifting of the laser focus or oscillate the laser focal point in and out of focus. Various duty cycles, focal positions and energy densities can be programmed, varied and fine–tuned as per application. Additional process controls can be added as required.

Material ablation–Laser material ablation can be accomplished through the use of adaptive optics utilizing a two–step focus method. The adaptive optic can rapidly adjust the focus so that a laser operating at high power can ablate closely spaced, deep parallel lines across a workpiece. The adaptive optic can then readjust the focus so that a laser now operating at low power can smooth the peaks of material between the rough–cut parallel lines.

Laser sawing–Laser beam sawing is a new cutting technology using adaptive optics for thick–section metal sheet cutting, which oscillates the focus position at high–speed during the cutting process. This technique allows a laser to cut thicker materials while reducing the roughness of the kerf, by improving the interaction between the beam and the material.

Intelligent laser process head–Several specialized intelligent laser process head systems are currently in development. These systems will incorporate an adaptive optic with several combinations of clearance and plasma sensors, diffractive optics, dual–purpose nozzles and interchangeable nozzles. Some designs can be interfaced directly with the laser and motion system parameters to provide real–time corrections. Additional designs will move the laser focus several millimeters into otherwise inaccessible profiles, switch automatically between processes on different materials and track across three–dimensional surfaces. The systems will also cut materials cleanly by sawing the focal point up and down. Future prototype systems can be fitted with a dual–purpose nozzle/auto–change nozzle system to allow a laser to switch between cutting and welding while working on the same component.

Conclusion

With a current installation base of more than 1000 units worldwide, adaptive optic technology has opened new applications and provides new solutions to industrial laser processing.

Gilbert J. Haas is the president of Haas Laser Technologies Inc., the exclusive distributor for Diehl Adaptive Optics in the U.S. Contact him at Tel. (973) 598–1150 or e–mail at sales@ haaslti.com.