Mark Eisenmenger and Daniel Szymanski

Through innovations in technology, TWB Company has introduced a break-through product: tailor welded coils that bring the advantages of tailor welded blanks to coil-fed forming operations. With increasing corporate average fuel economy (CAFE) standards being imposed combined with consumer demand for more fuel efficient vehicles, the automotive industry is compelled to explore new and innovative ways to systematically and strategically remove weight and costs from the vehicle structure. The challenge (and opportunity) to improve fuel efficiency and lessen the effect of CO2 emissions, while making vehicles safer, is a daunting task for automotive engineers. For example, reducing total vehicle weight by 100 kg improves the average fuel economy by 8%.With the continued growth of new advanced high strength and ultra-high strength steel grades, materials can be selectively used where they are needed. This tailored approach enables a flexible part design that fully optimizes the properties in a single stamped part. The combination of optimum steel grades allows for improved part performance related to crash behavior and energy absorption needed to achieve the coveted five star safety rating.

How it all began...

Laser welded, tailored blanks were first produced in the mid-1980s by Germany's ThyssenKrupp Steel AG to meet the escalating technological needs of the automotive industry. The first mainstream application for a tailor welded blank resulted from a need to produce a part that was wider than the hot-dip galvanizing line could coat at that time. The ThyssenKrupp solution was to laser weld two sheets of the same steel together to produce the part to meet their customer's needs. The results were so positive that in 1985, the decision was made to produce laser welded blanks on a large scale at ThyssenKrupp's Duisburg facility. The manufacture of tailor welded blanks has since evolved to encompass welding steels of varying thickness, coatings, and material grades, including stainless and carbon steels in all combinations.

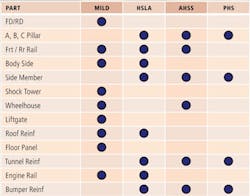

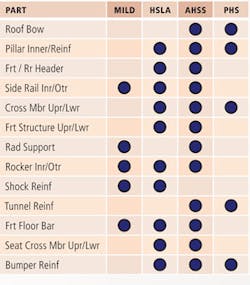

The TWB Company, based in Monroe, Michigan, was formed in 1992 as a joint venture between Worthington Industries Inc. and ThyssenKrupp Steel AG. The joint venture has become a North American market and technology leader for these tailored solutions. TWB's global network includes ThyssenKrupp Tailored Blanks (TKTB), and a dedicated machine designer for tailored products, which has extensive tailor welded blank and tailor welded coil operations throughout Europe and Asia.Tailor welded blanks are commonly applied to over 18 automotive applications; some of the more frequent include inner door panels, inner body side panels, pillars, side members, and rails. Part consolidation, part optimization, and improved material utilization save piece cost, tooling investment, and weight in automotive structural body panels. As OEMs continue to design and produce a greater number of global vehicle platforms, they must rely more heavily on tiered suppliers that can support their worldwide operations like TWB and TKTB.

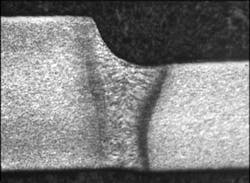

TWB utilizes a patented flow-through continuous laser welding technology that incorporates a pressure roller drive system to traverse the blank through a stationery laser beam. This results in high process reliability and an efficient blank welding technology. The company uses CO2 or fiber laser technology as the laser source on all of its blank and coil welding lines.

All weld seams are fully monitored to assure quality and reliability using a proprietary magnetic flux leakage detection system that measures internal weld discontinuities to a resolution of 0.3 mm. This is further integrated with a real-time profile monitoring system with weld geometry resolution to 0.03 mm.

Tailor welded coil evolution

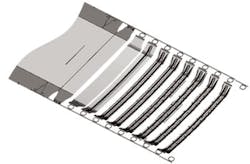

TWB has taken its continuous laser welding technology to the next level and is extending the capability to joining coils together, edge to edge. These coils can then be used in coil-fed processes such as blanking, progressive die stamping, transfer press stamping, and roll forming operations. This technology leap has opened the door for new parts that can be tailored with steel grade, gauge, and coating combinations. Tailor welded coils provide a cost effective solution to applications where using traditional welded blanks has not been possible. This has attracted the attention of automotive product and manufacturing engineers and also non-automotive industries that primarily use coil-fed processes.In addition to the previously stated benefits realized by tailored products, tailor welded coils can expand the steel coil width availability for many steel grades. Most high strength, advanced high strength, and ultra-high strength steels have a limited rolling width that can be produced while still maintaining uniform properties. By expanding the widths of these higher strength steels, TWB gives greater flexibility to the manufacturing engineers; parts can now be designed as a single stamped component rather than as multiple components that are subsequently sub-assembled downstream. Tailor welded coils provide widths of up to 2.5 m that can be used on the largest coil feeders in the world.

Progressive die stamping and roll forming operations are the most efficient forming operations available, resulting in substantial stamping cost and weight savings when used with tailor welded coils. This technology also increases the throughput of coil-fed transfer and tandem press lines that are typically less efficient when feeding individual blanks. Over 45 tailor welded coil applications have been identified in automotive body structures that, when implemented, can save over 35 kg of weight. A few of the parts that can be processed as tailor welded coils include: roof bows, headers, pillar reinforcements, cross members, front structures, seating, and exhaust system components.

Slit coils varying in width from 75 mm to 1500 mm, with gauge ranges of 0.6 mm to 3.0 mm, can be loaded into TWB's coil welding line. They pass through individual in-line leveling stations that are designed to handle material strengths up to 980 MPa. The individual coils are then simultaneously fed through the fixed-position 6 kW fiber-delivered laser powered welding station, where they are joined. The welded coils are then re-coiled under tension to full size and ready for customer forming processes.

Coils with multiple weld seams made up of three individual coils are passed through the welding station a second time. Most coils are typically made by joining three coils with two separate welding seams.

When winding coils of dissimilar thickness, coils will inherently wind to the thicker gauge. As long as coils have a thick width to overall width ratio of approximately 40% or greater, they can be rolled to full size (35 tons). Coils with a thick width to overall width ratio under 40% are wound to less than full size.

Another issue successfully addressed is coil length equalization. As coils of dissimilar thickness tend to vary in length, TWB equalizes them in an efficient and cost effective way. The coil welding line is able to add shorter coil strips together inline, while leaving a small gap between the head and tail of coil strips to be welded. This small gap creates a defect in the welded coil, which is identified and mapped, but remains a cost effective way to maximize material utilization.Summary

Tailor welded coil technology brings industry proven tailor welded blank advantages to the most efficient forming operations: i.e. progressive stamping and roll-forming. This offers the automotive engineer another tool to achieve mandatory CAFE regulations while meeting consumer demands. This is accomplished by optimizing the existing material supply base and stamping infrastructure to obtain significant weight savings.

Tailor welded coils are an example of TWB's effort to expand tailored solutions to new automotive applications and to other industries.

Mark Eisenmenger ([email protected]) is the manager for new product development at TWB (www.twbcompany.com) and Daniel Szymanski is responsible for the North American tailor welded coil product line.